Method for detecting compressive strength of concrete by body sampling

A compressive strength, concrete technology, applied in the direction of strength characteristics, measuring devices, material inspection products, etc., can solve the problems of limited use, low precision, detection error and high detection cost, so as to ensure accuracy and realize representative sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

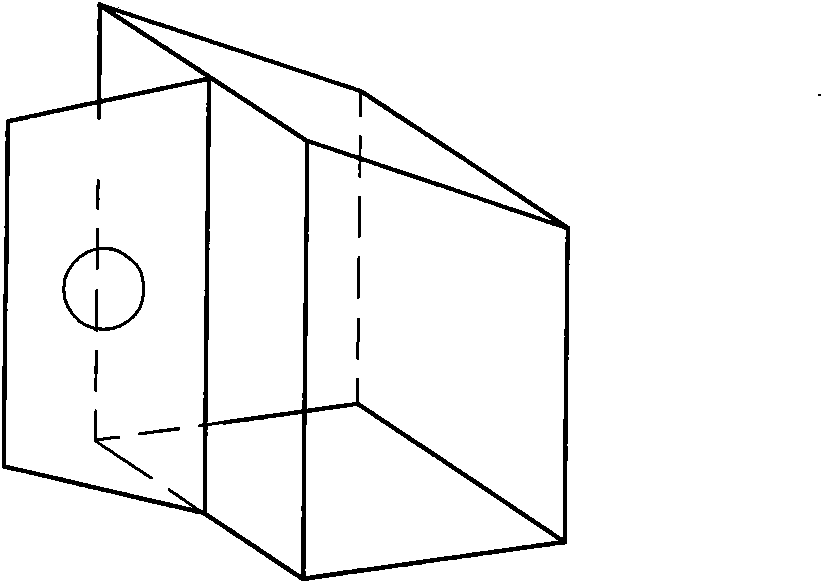

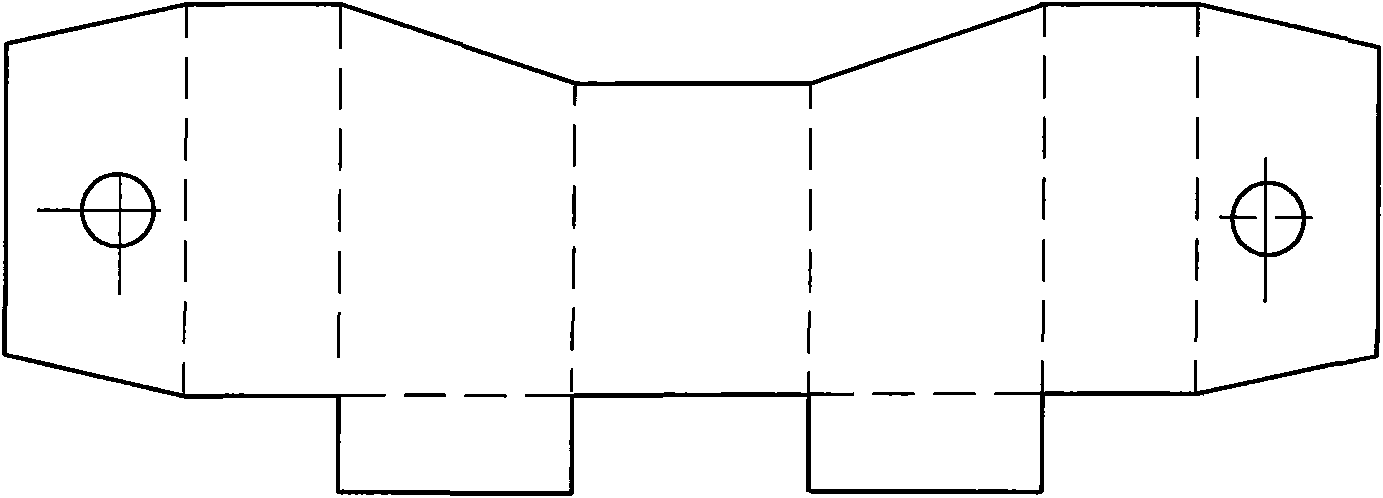

[0019] Q235 steel plate is used, the thickness is 2.0mm, the net size of the mold box is set as length × width × height = l × b × h = 100mm × 100 × 120mm, pressed into the attached figure 1 The mold box shown is used for pre-embedding in cast-in-place concrete components. When assembling the formwork of cast-in-place components, the mold box is suspended and fixed on the inside of the formwork. When pouring component concrete, a concrete compression test is formed in the mold box pieces. When the same conditions as the cast-in-place concrete components are maintained and reach the age, take out the mold box, and then take out the concrete specimen in the mold box, according to length × width × height = l × b × h = 100mm × 100 × 100mm, cut After grinding, the compressive data is obtained on a pressure testing machine.

Embodiment 2

[0021] Q235 steel plate is used, the thickness is 1.5mm, the net size inside the mold box is set as length × width × height = l × b × h = 80mm × 80 × 100mm, pressed into attached figure 1 The mold box shown is used for pre-embedding in cast-in-place concrete components. When assembling the formwork of cast-in-place components, the mold box is suspended and fixed on the inside of the formwork. When pouring component concrete, a concrete compression test is formed in the mold box pieces. When the same conditions as the cast-in-place concrete components are maintained and reach the age, take out the mold box, and then take out the concrete specimen in the mold box, according to length × width × height = l × b × h = 80mm × 80 × 80mm, cut After grinding, the compressive strength of the specimen is obtained on the pressure testing machine, which is used to detect and evaluate the compressive strength of the cast-in-place concrete body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com