Pipelining emergent repairing method of prestressing steel cylinder concrete pipe

A technology of concrete pipes and prestressed steel, applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., can solve the problems of large waste, high cost, and long repair time, and achieve low cost and short repair time , the effect of not wasting water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

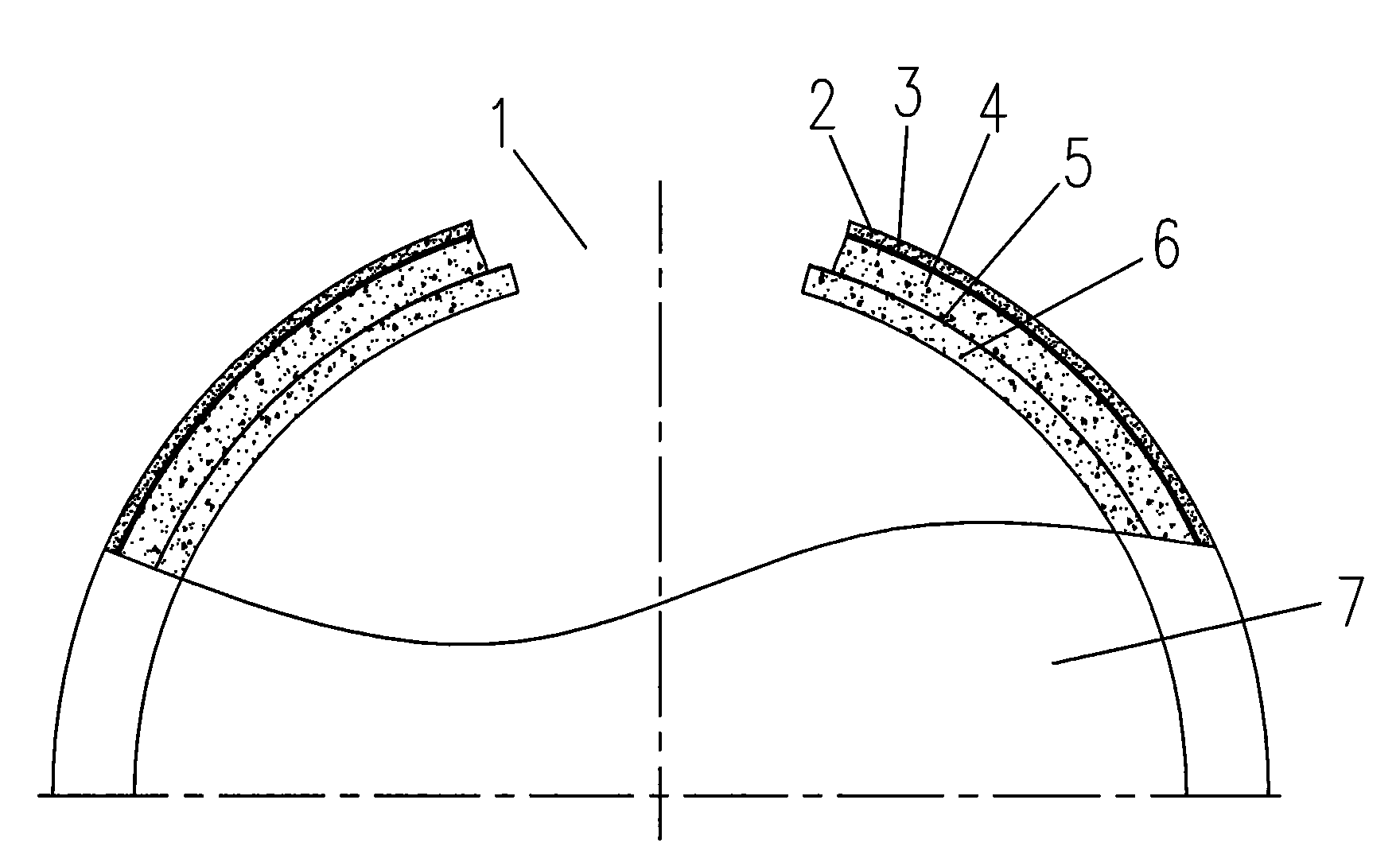

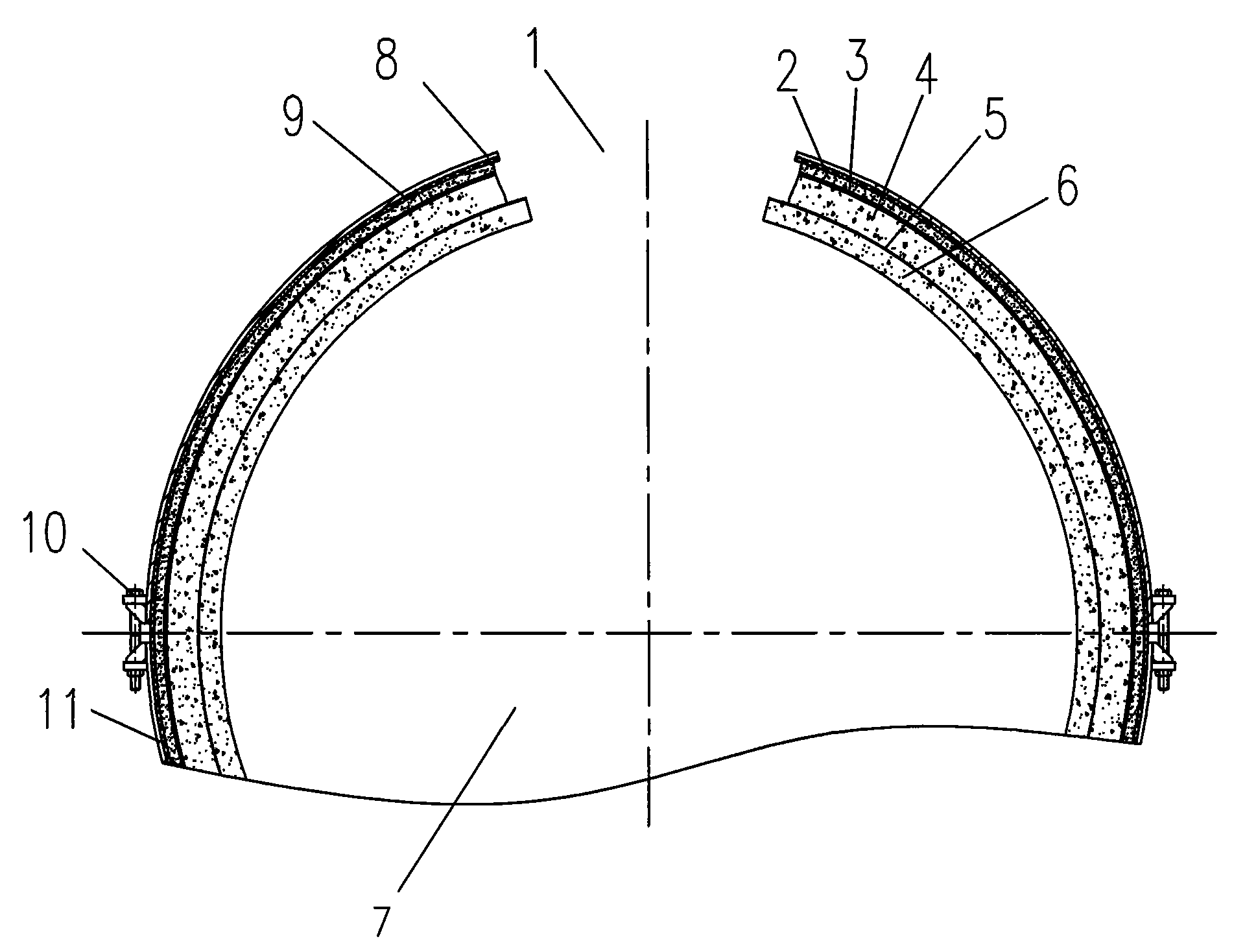

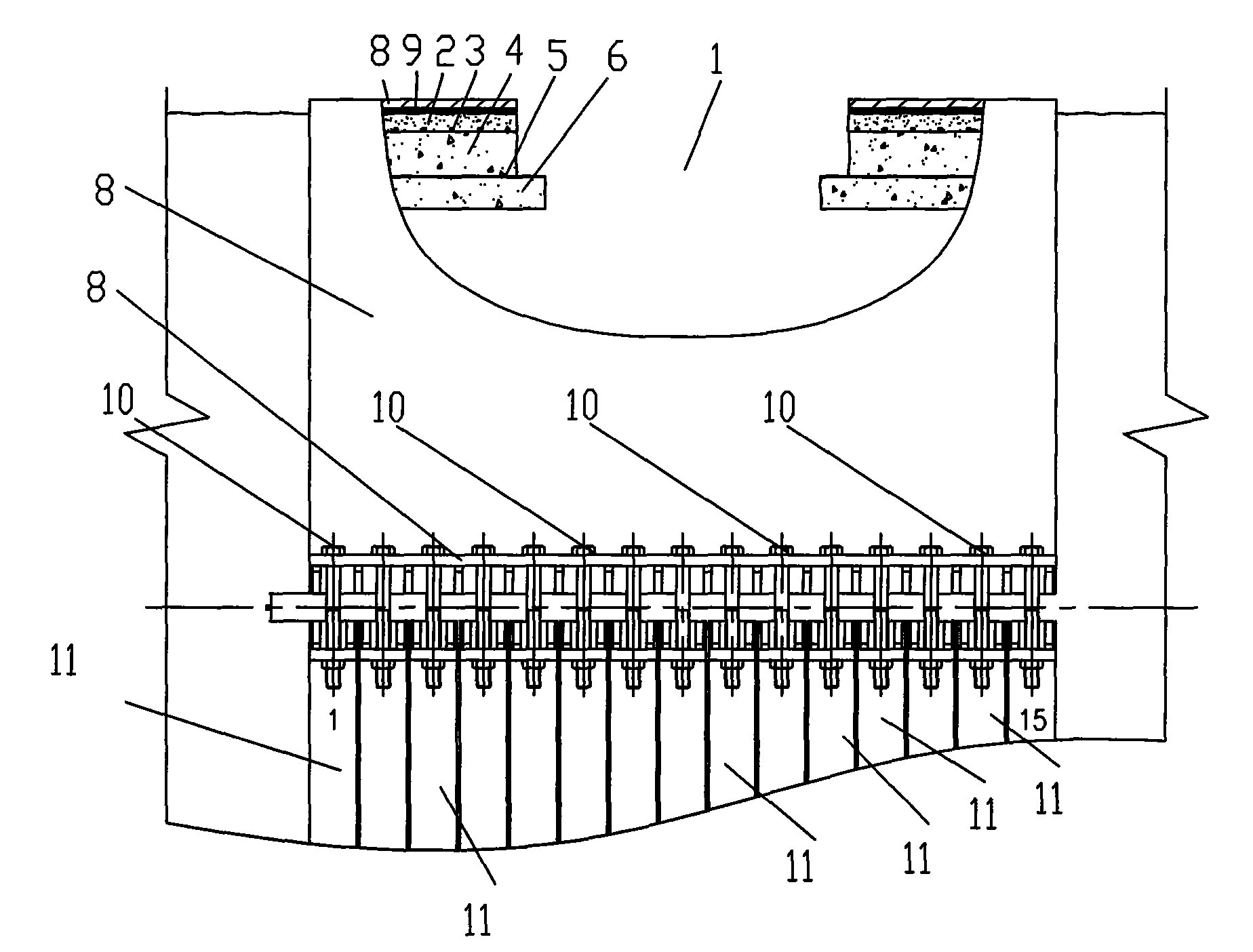

[0026] The method comprises the steps of:

[0027] Step 1, setting the lining plate 13: place a lining board 13 on the inner wall corresponding to the damaged hole 1 on the pipeline, the radian of the lining board 13 coincides with the inner wall radian of the pipeline; the lining board 13 The size should ensure that the inner liner 13 can be put into the pipeline through the damaged hole 1, and after being put in, it can completely cover the damaged hole 1 on the inner wall of the pipeline, and a bracket 12 is set outside the pipeline corresponding to the damaged hole 1 ;

[0028] Step 2, install the cover plate: put the cover plate 18 and the top plate 17 on the screw rod 16, and then connect the screw rod 16 to the inner lining plate 13; set the cover plate hole 22 on the cover plate 18; The liner 13 is connected to the bracket 12 by the screw 16;

[0029] Step 3, repairing the inner tube core: fill the pit corresponding to the inner liner 13 on the pipeline with concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com