Fire-fighting sprinkler head with circular-arc nozzle

A sprinkler head, arc-shaped technology, applied in the field of fire extinguishing equipment, can solve the problems of delaying fire extinguishing time, wasting fire extinguishing agent, etc., and achieve the effects of less fire extinguishing agent, low fire extinguishing cost, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

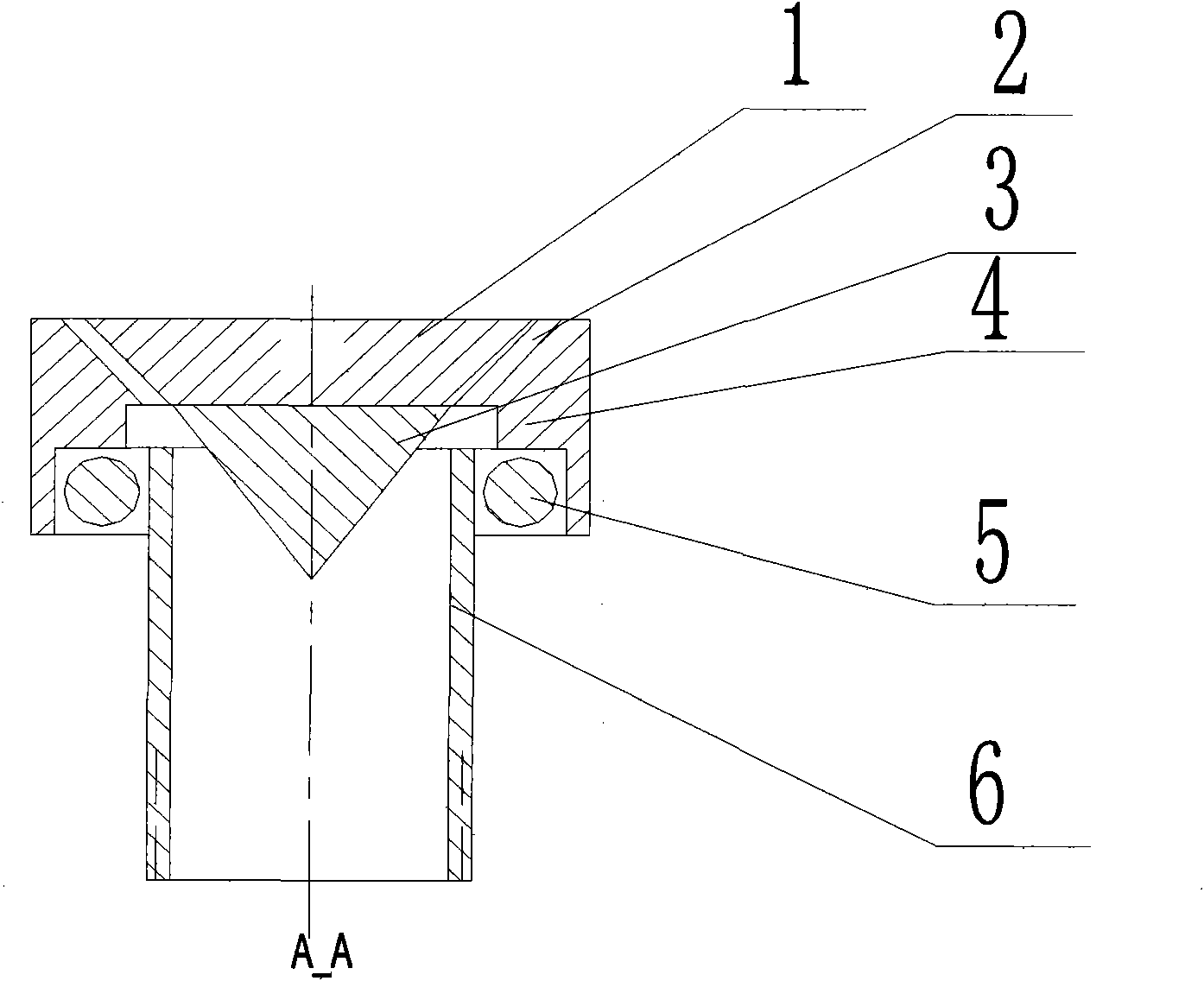

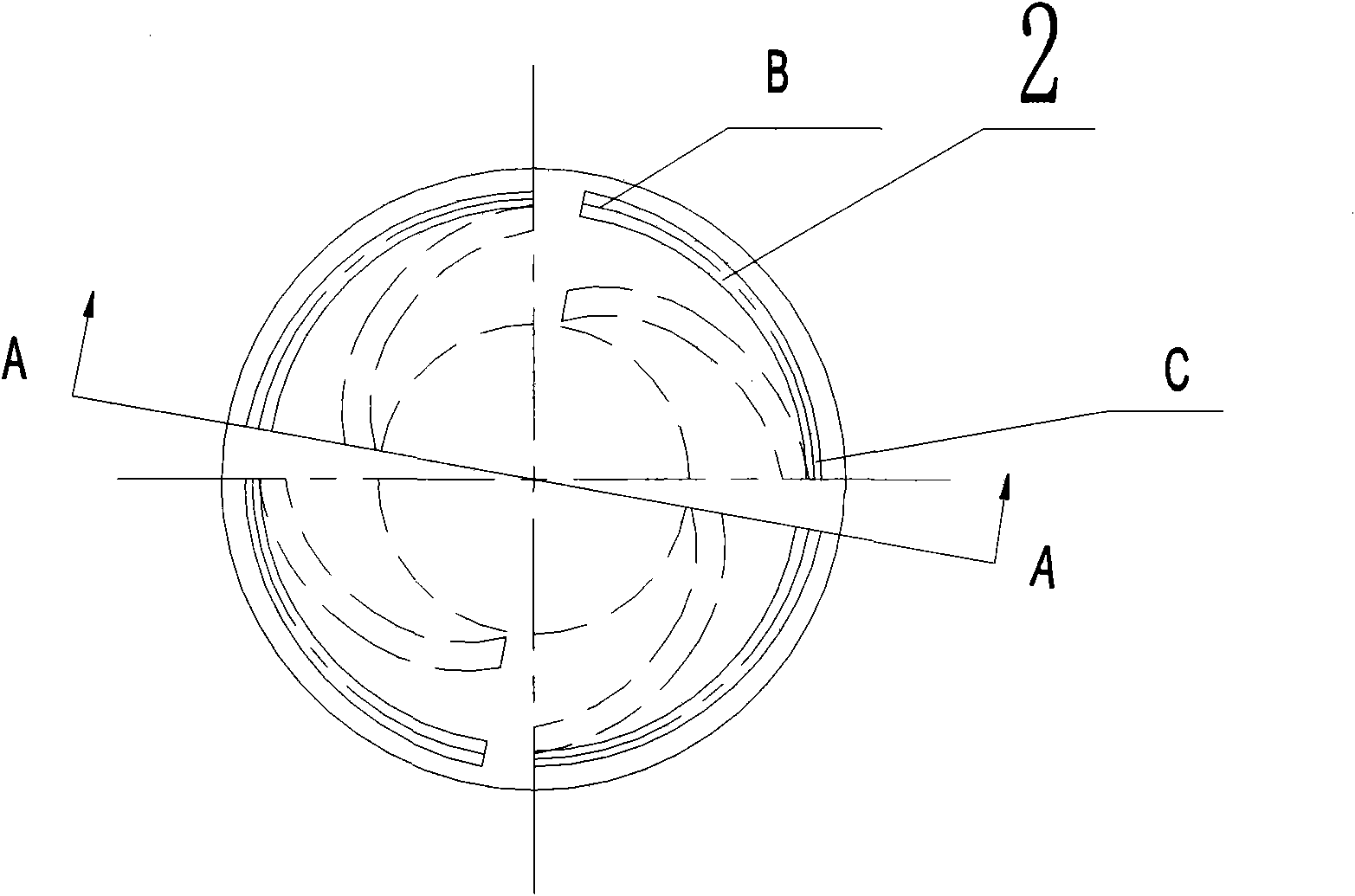

[0014] see figure 1 with figure 2 , the fire sprinkler head with arc-shaped nozzle includes sprinkler head body 1, bearing 5, cone 3 and connecting pipe 6. The sprinkler head body 1 is a stainless steel cylinder with a diameter of 60 mm and a thickness of 10 mm. There are four arc-shaped nozzle grooves 2 evenly distributed on the top circumference of the sprinkler head body 1. The equation of the centerline of the arc nozzle at the upper end of the sprinkler head body 1 is: x=rcost, y=rsint, where the arc base circle radius r is 27mm, the arc spread angle t is 0-4π / 9, and a certain injection angle is formed between the axial lower end and the axial upper end of the nozzle groove 2, the injection The size of the angle changes uniformly from the starting end B of the nozzle groove at the upper axial end to the terminal end C end, and the width between the axial lower end and the axial upper end of the nozzle groove 2 also changes uniformly; The spray angle is 70°, the outlet ...

Embodiment 2

[0018] The diameter of the sprinkler head body is 40mm, and the thickness is 8mm; there are three arc-shaped nozzle slots evenly distributed on the top circumference of the sprinkler head body. The groove width is 1.5mm, and the groove width of the outlet at the upper axial end is 1.0mm; the injection angle at the B end of the nozzle groove 2 is 45°, where the groove width of the inlet at the lower axial end of the nozzle groove is 2.0mm, and the groove at the outlet at the upper axial end The width is 1.5mm; the arc base circle radius r is 18mm, the arc spread angle t is 0~11π / 18, the bearing 5 is a K811 series flat seal with an inner ring waterproof bearing with an outer diameter of 35mm and an inner diameter of 20mm, and a connecting pipe 6 The length is 100mm and the outer diameter is 20mm.

[0019] Others are with embodiment 1.

Embodiment 3

[0021] The diameter of the sprinkler head body is 50mm, and the thickness is 10mm; there are two arc-shaped nozzle slots evenly distributed on the top circumference of the sprinkler head body. The groove width of the nozzle groove is 2.0mm, the groove width of the outlet at the upper axial end is 1.5mm; the jet angle at the B end of the nozzle groove starting end is 45°, here the groove width of the inlet of the lower axial end of the nozzle groove is 2.3mm, and the groove of the outlet at the upper axial end The width is 2.0mm; the arc base circle radius r is 22mm, the arc spread angle t is 0~17π / 18, the bearing 5 adopts the K811 series flat seal with an inner ring waterproof bearing with an outer diameter of 42mm and an inner diameter of 25mm, and the connecting pipe 6 The length is 100mm and the outer diameter is 25mm.

[0022] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com