Reinforced type lead wire damping spacer

A reinforced, spacer bar technology, applied in the direction of maintaining the distance between parallel conductors, mechanical vibration damping devices, etc., can solve the problems of twisting deformation and fracture damage of line fittings, improve torsion resistance, compensate for creep relaxation effect, Easy to install and remove effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

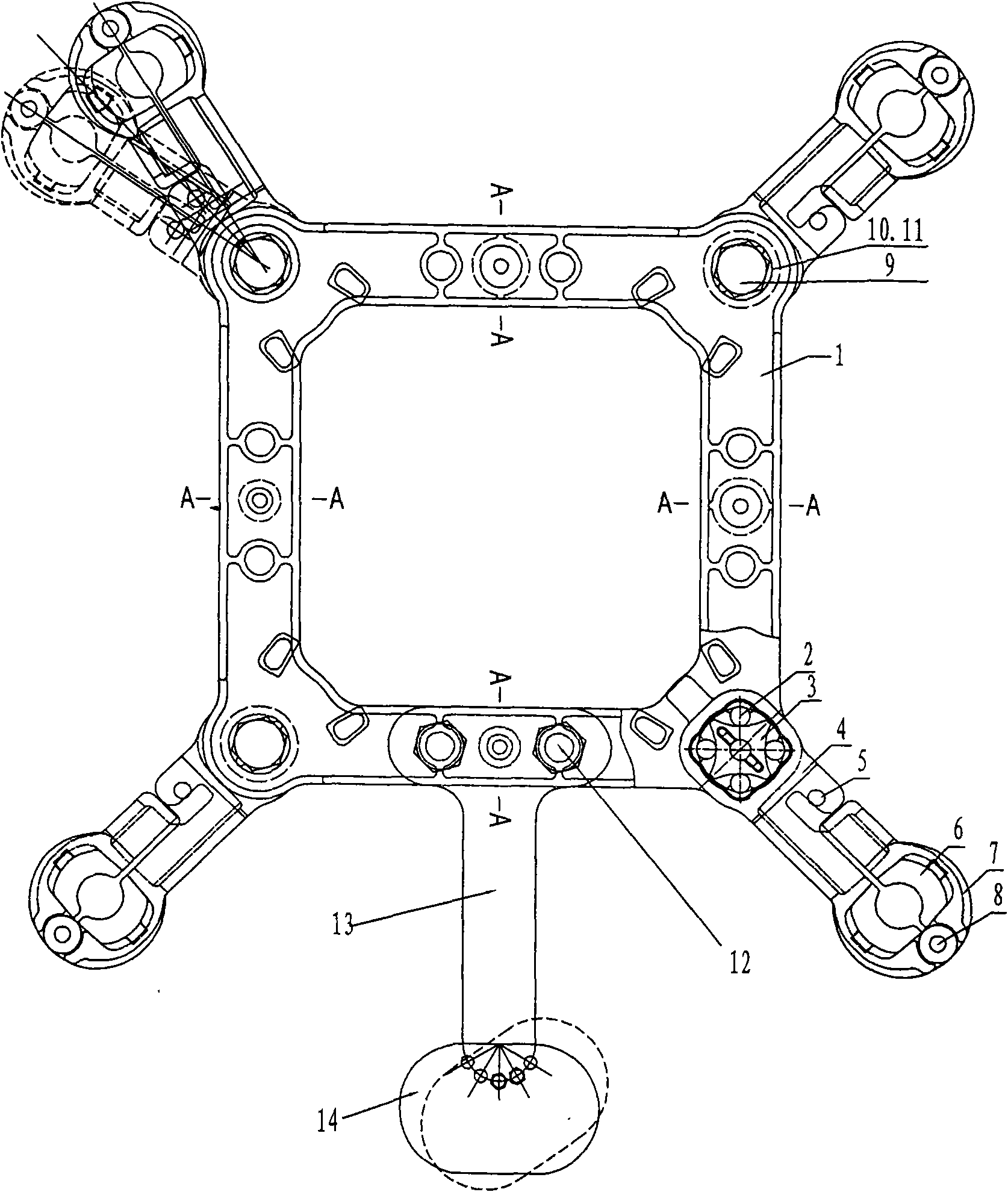

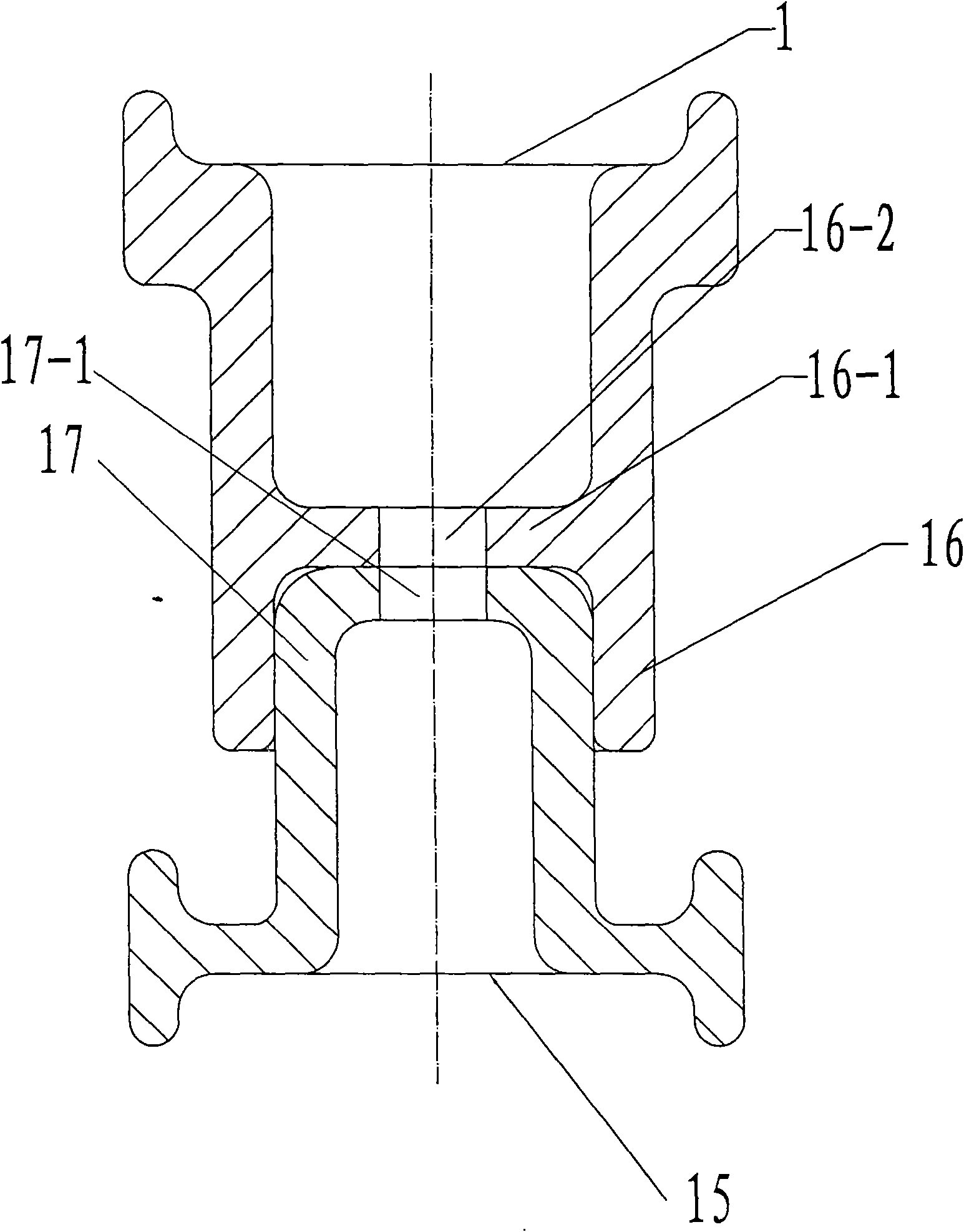

[0021] Such as figure 1 with figure 2 As shown, this reinforced wire damping spacer includes an upper frame 1, a lower frame 15, four clamp bodies 4 and a cover plate 7, and the upper frame 1 and the lower frame 15 are square frame bodies. One end of the clamp body 4 is built with a cross sleeve 3 , and eight damping rubber columns 2 are arranged around the cross sleeve 3 . The clamp body 4 is integrally connected with the upper frame 1 and the lower frame 15 through bolts 9, nuts 10 and washers 11. The other end of the clamp body 4 is integrated with the cover plate 7 through the hinge pin 8. The clamp body 4 And the cover plate 7 is provided with a rubber pad 6 suitable for any wire, and the wire is installed in the groove formed by the rubber pad 6 and fixed by the locking pin 6 .

[0022] Between the upper frame 1 and the lower frame 15, there are 4 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com