Karman vortex flowmeter assembly comprising a fiber Bragg grating sensor and method to measure a fluid flow rate

A technology of fiber optic Bragg and Karman eddy current, applied in the direction of detecting the dynamic effect of fluid flow, measuring flow/mass flow, volume measurement, etc., can solve the problems of difficult calibration of sensors, drift of measurement results, and inaccurate sensors, etc., to achieve good results Reproducible, accurate flow rate measurement results, reliable measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the present application, the same or corresponding features are denoted by the same or corresponding reference numerals.

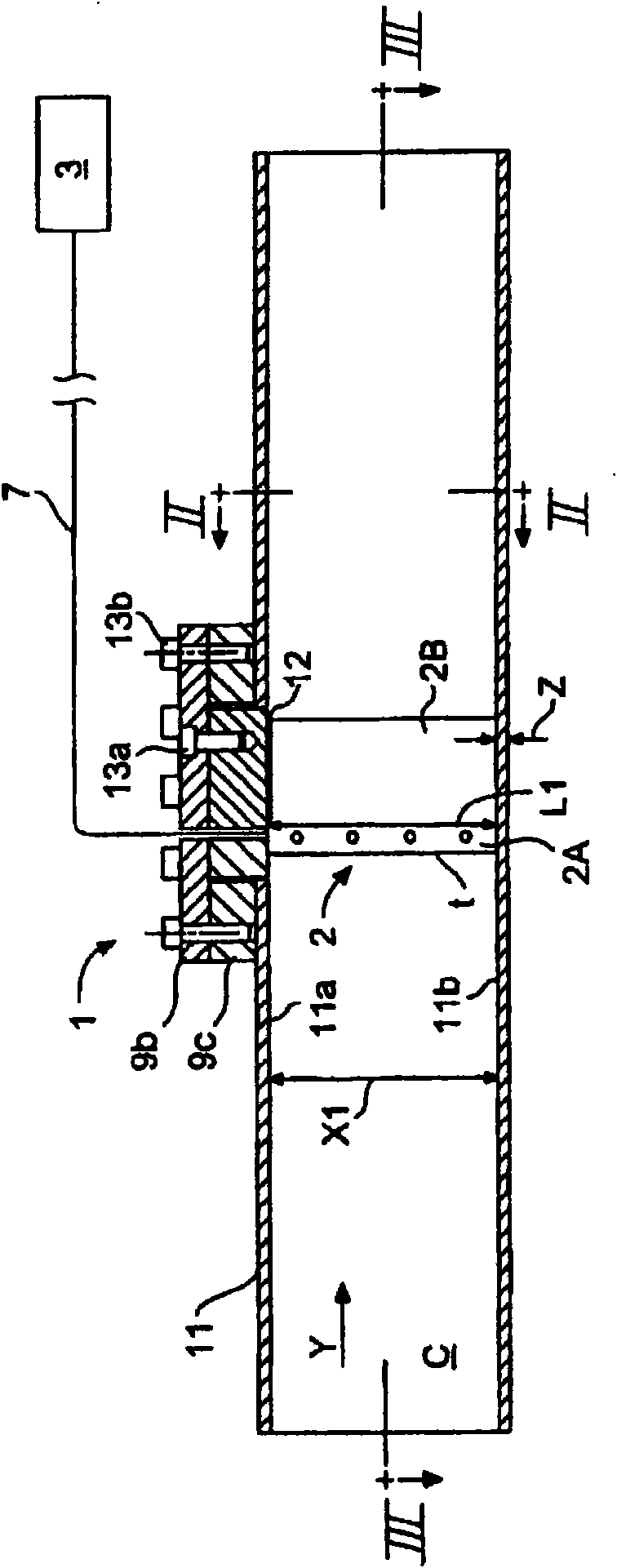

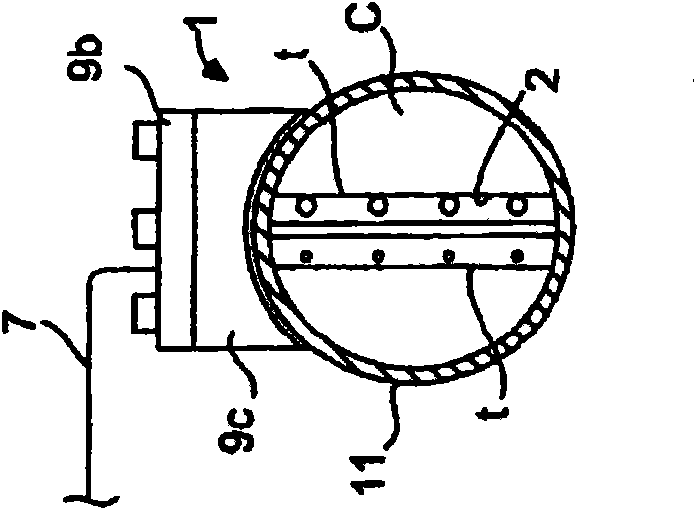

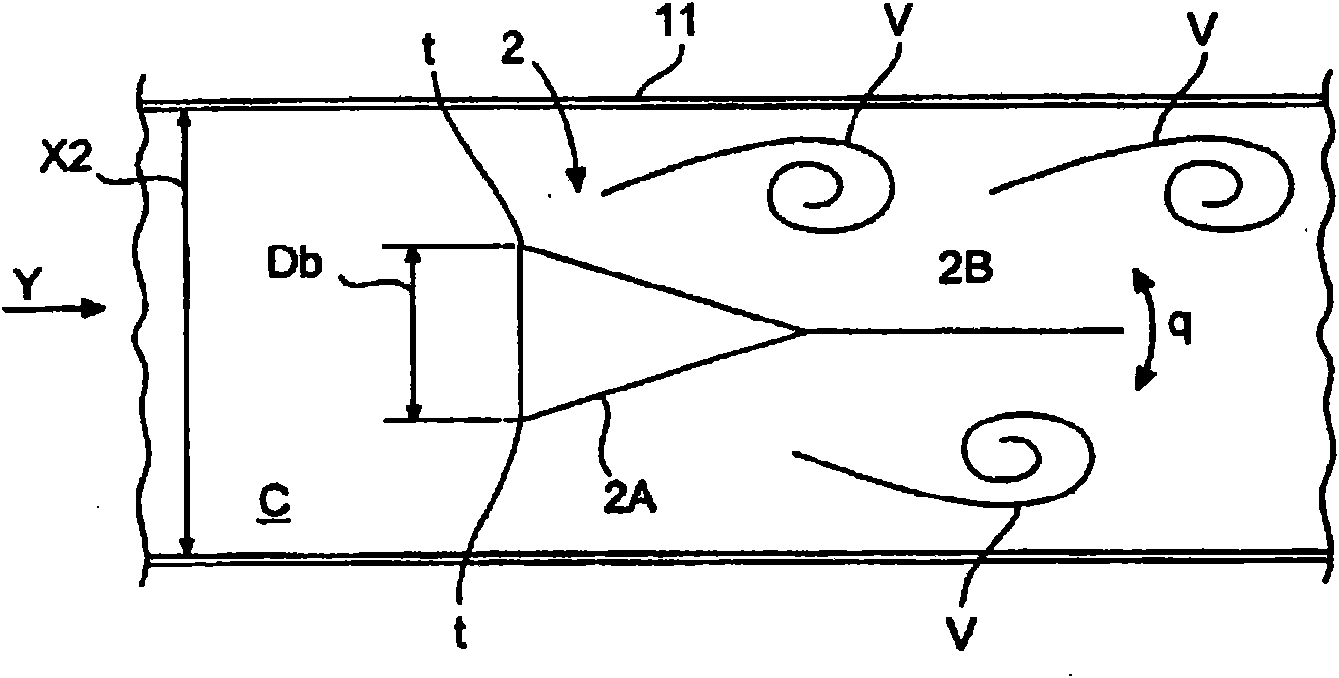

[0029] Figure 1-6 A non-limiting embodiment of an assembly comprising a fluid channel C and a flow meter 1 is shown.

[0030] Fluid channel C (for example, fluid line, fluid tube, fluid channel (fluid line / pipe / conduit) can be configured to guide fluid, for example, gas, gas mixture, air, liquid, liquid mixture, water, steam. In particular In the embodiment, the channel C may be configured to inject fluid into an oil or gas field, however, the skilled person will understand that the channel C may be used in many other applications. In this embodiment, the channel C has a diameter (width ) a substantially circular cross-section of W. The skilled person will understand that the channel may also have a different configuration, for example have a rectangular or square cross-section, or a different cross-section.

[0031] The flow meter 1 is config...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com