Double rotor type motor

A dual-rotor, motor technology, applied in the motor field, can solve the problems of increasing the size of the washing machine, increasing the size and weight of the motor, etc., achieving the effects of simple and precise positioning, improving productivity, and shortening the time period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

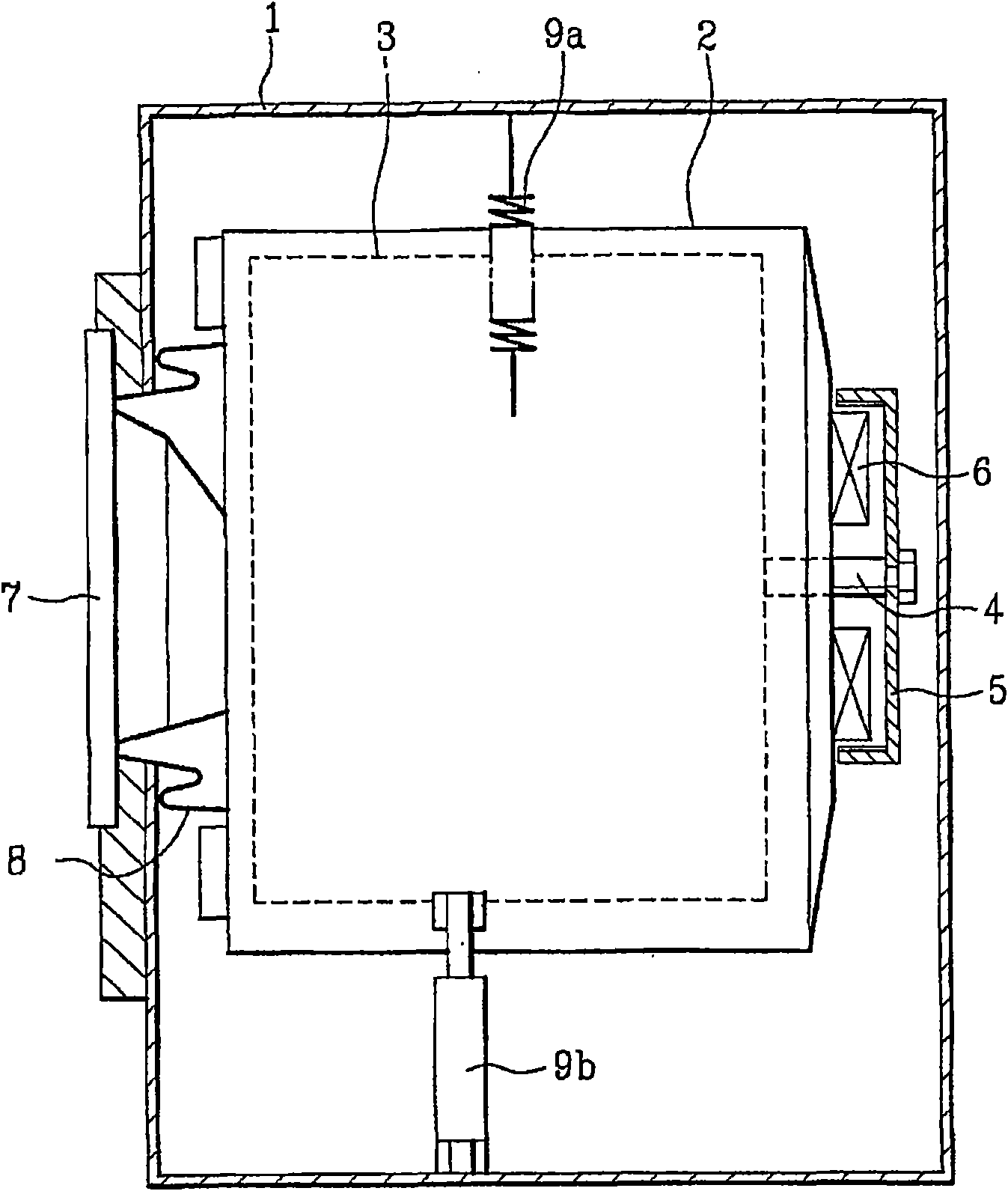

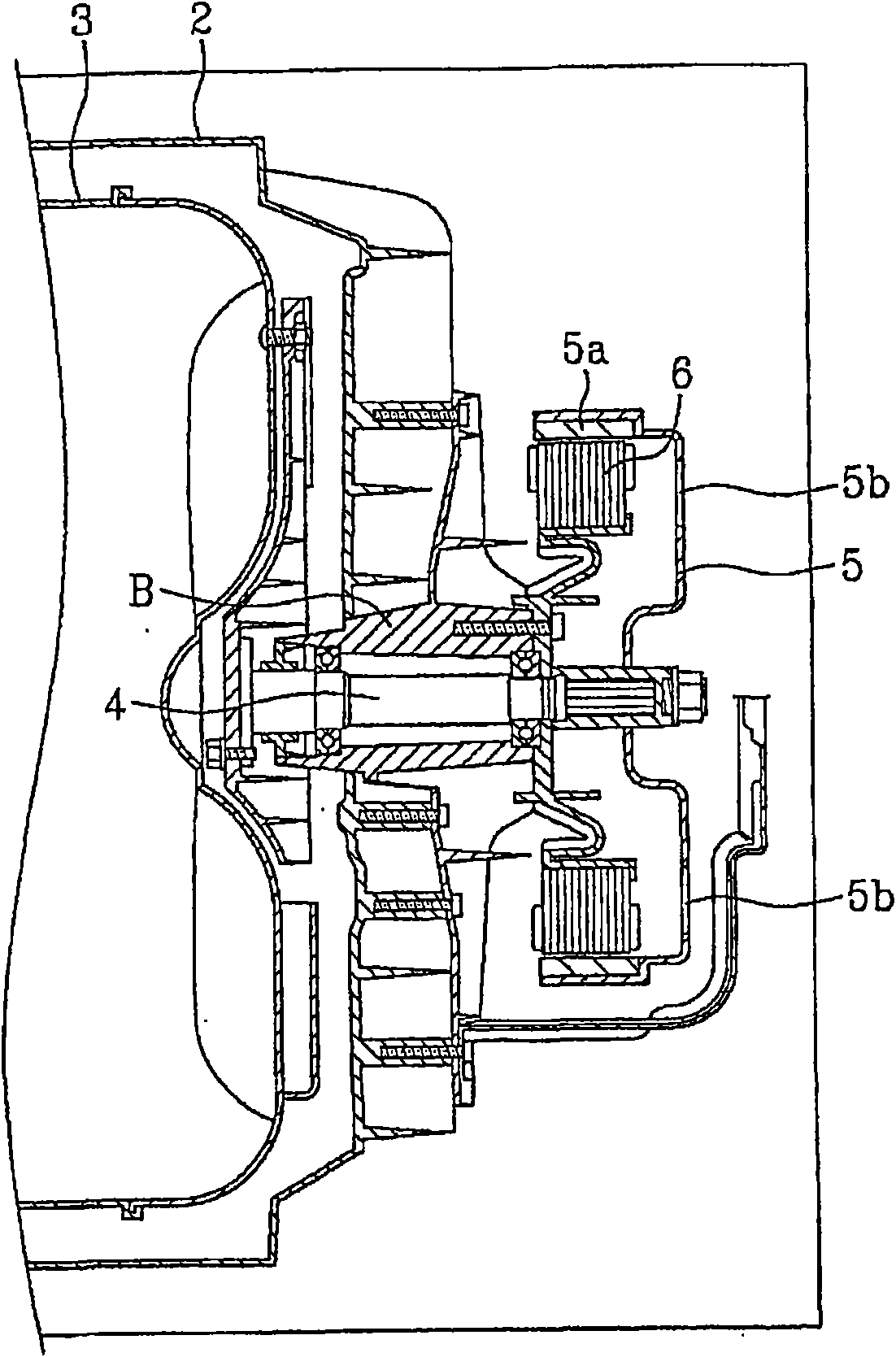

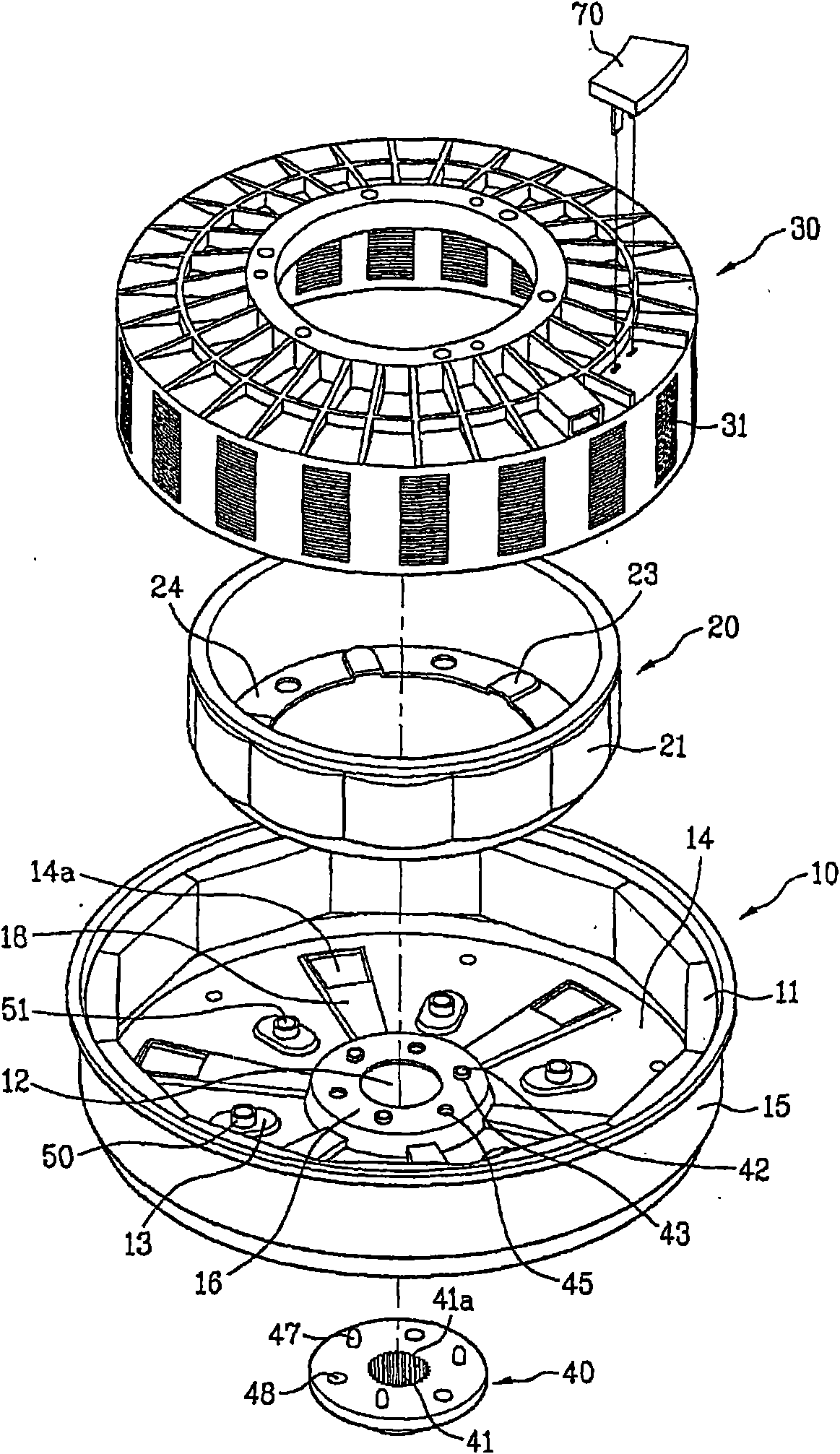

[0070] refer to Figure 3 to Figure 11 , a dual rotor type motor according to a first preferred embodiment of the present invention will be described.

[0071] image 3 shows an exploded perspective view of a dual rotor type motor according to a first preferred embodiment of the present invention, while Figure 4 A cross-section of a part of a dual-rotor type motor and a motor mounting portion according to a first preferred embodiment of the present invention is shown.

[0072] refer to image 3 , the dual-rotor motor includes an inner rotor 20 , an outer rotor 10 and a stator 30 . The stator 30 is disposed between the outer rotor 10 and the inner rotor 20, and the top surface of the stator 30 is fixedly fastened to a bearing housing installed at the rear of the tub of the washing machine. On one side of the stator 30, a Hall sensor 70 for detecting the rotational speed of the dual rotors is provided.

[0073] The stator 30 includes an exposed core 31, and is opposed to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com