Drive trains for motor vehicles

A technology of drive train and motor vehicle, applied in the field of drive train for motor vehicles, which can solve the problems of unfavorable service life, uncomfortable startup and shutdown of internal combustion engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

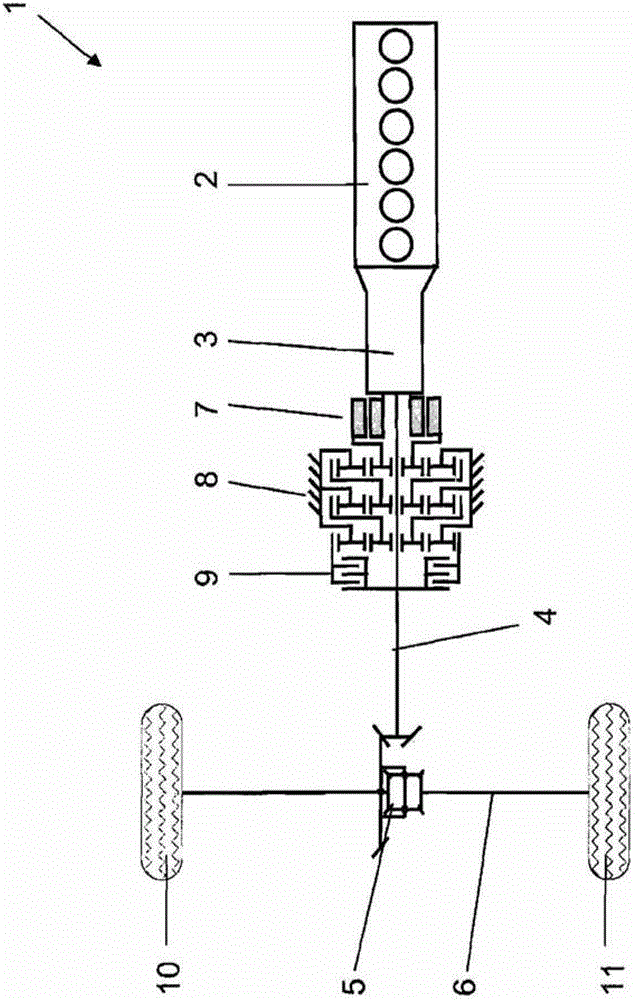

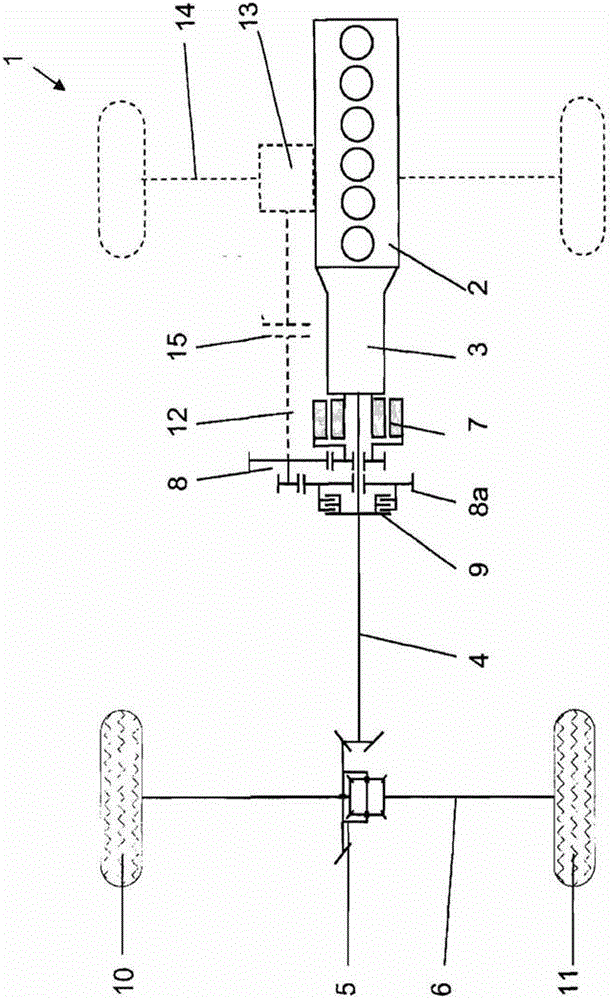

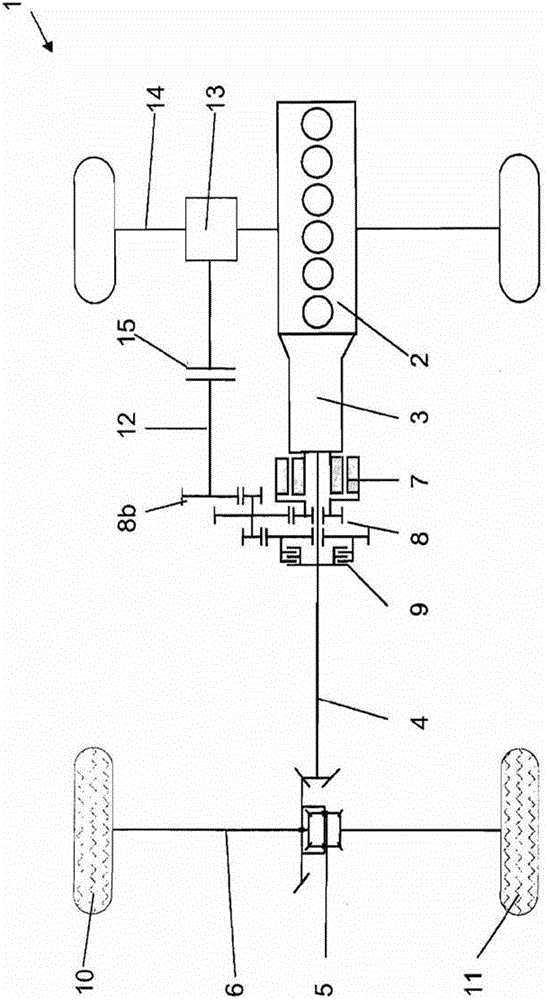

[0023] figure 1 A drive train 1 is shown, which is used, for example, in a motor vehicle. Here, a main prime mover 2 in the form of an internal combustion engine is connected to a main transmission 3 with a transmission output shaft 4 , which leads to a first axle differential 5 arranged on a drive shaft 6 of the motor vehicle. Based on this configuration, the main prime mover 2 drives the wheels 10 , 11 connected to said first drive shaft 6 .

[0024] The electric motor 7 designed as an outer rotor mounted as an auxiliary prime mover is connected to an auxiliary transmission 8 , which in turn is designed as a single-stage or multi-stage planetary transmission. The last transmission stage 8 a of the auxiliary transmission 8 is connected here to a coupling element 9 in the form of a clutch, which connects the electric motor 7 to the transmission output shaft 4 or disconnects this connection. The electric motor 7 and the auxiliary transmission 8 are arranged as a compact unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com