Rotary pot holder

A technology of rotating pots and ring columns, applied in the direction of the cooker's support, etc., can solve the problems of uneven spreading, troublesome work, and no solution, etc., and achieve the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

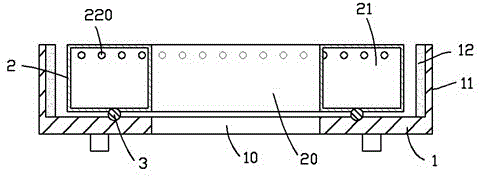

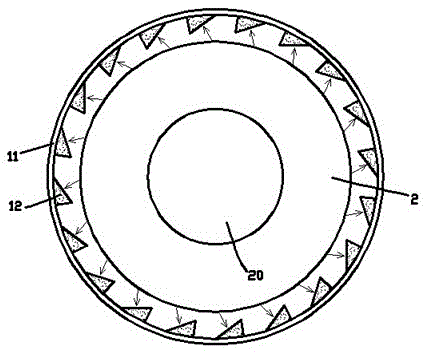

[0013] exist figure 1 , figure 2 In the first embodiment shown, the rotary pot seat includes a base 1, the base 1 is in the shape of a barrel with an opening facing upwards; the bottom surface of the base 1 is provided with a flame hole 10 for allowing the lower flame to escape into the base; the base 1 An annular column 2 is surrounded inside; the interior of the annular column 2 is an annular cavity 21 that can be injected into water; the upper peripheral wall of the annular cavity 21 is provided with a circle of air holes 220, and each air hole 220 is along the side of the outer peripheral wall. to the air outlet, and the angle between the air outlet direction of each air hole 220 and the radial direction of the air hole is equal, that is, when each air hole 220 is ejected at the same air outlet speed, the gas ejected in each air hole will generate a large impact on the annular cavity 21. Equal torque; the side wall 11 surrounding the annular column 2 on the base 1 has re...

Embodiment 2

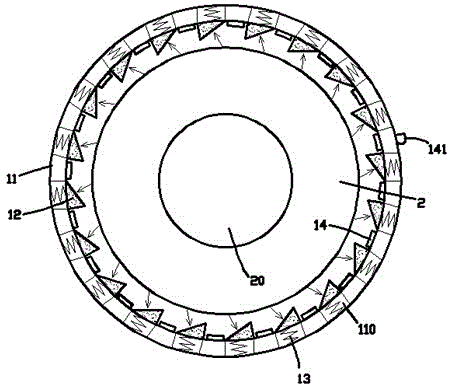

[0016] image 3 Shown is the second embodiment of the rotary pot seat, which is different from the first embodiment in that: the recoil slopes 12 on the side wall 11 of the base 1 are movable components, and pass through the side wall 11 The spring 13 in the concave hole 110 is ejected from the concave hole; a section of arc-shaped sliding piece 14 is respectively arranged between each of the recoil slopes 12, and each of the arc-shaped sliding pieces 14 is fixed to each other to form a broken A continuous ring, a driving rod 141 leading to the outside of the side wall of the base 1 is fixed on the intermittent ring; when the driving rod 141 is moved along the side wall 11 of the base 1, the Each of the arc-shaped sliding pieces 14 on the intermittent ring presses against each of the recoil slopes 12 , and presses each of the recoil slopes 12 into the interior of the concave hole 110 .

[0017] The outstanding advantage of the second embodiment is that: when the pot body does...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com