Flat plate type solar phase-change heat-storage heat-supply and thermoelectric power generation composite system

A technology of phase change heat storage and temperature difference power generation, which is applied in the field of solar heat utilization, can solve the problems of large specificity of the thermal insulation tank of solar water heaters, and achieve the effects of saving production costs, simple devices, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

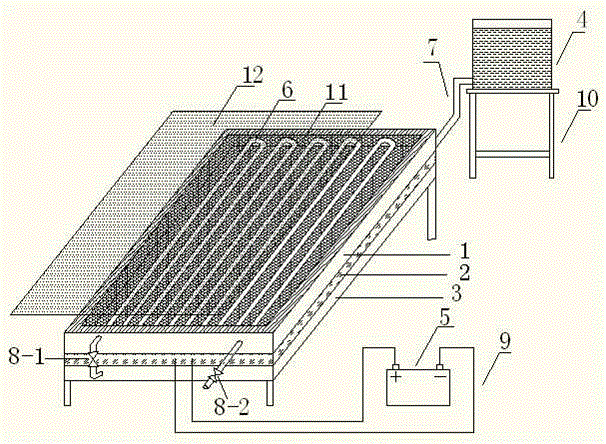

[0011] Such as figure 1 A flat-plate solar phase change heat storage heating and thermoelectric power generation composite system is shown, including a flat solar phase change heat storage heat supply device (1), a thermoelectric power generation device (2), a flat cooling water tank (3), water supply Box (4), battery (5), serpentine diversion coil (6), pipe (7), valve (8-1, 8-2), wire (9), bracket (10), phase change heat storage Material (11) and transparent insulating glass cover plate (12) etc. It is characterized in that the water outlet of the supplementary water tank (4) is connected with the upper water inlet of the flat cooling water tank (3) through the pipeline (7), and the lower water outlet of the flat cooling water tank (3) is connected with the valve (8) through the pipeline (7) -1) After that, it is connected to the inlet end of the serpentine diversion coil (6) placed in the flat-plate solar phase change heat storage heating device (1), and the outlet end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com