Liquid medicine barrel of sprayer

A sprayer and liquid medicine technology, which is applied in the field of sprayer liquid medicine barrels, can solve problems such as easy leakage of liquid at the connection, waste of liquid medicine, and inability to use the sprayer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0016] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings:

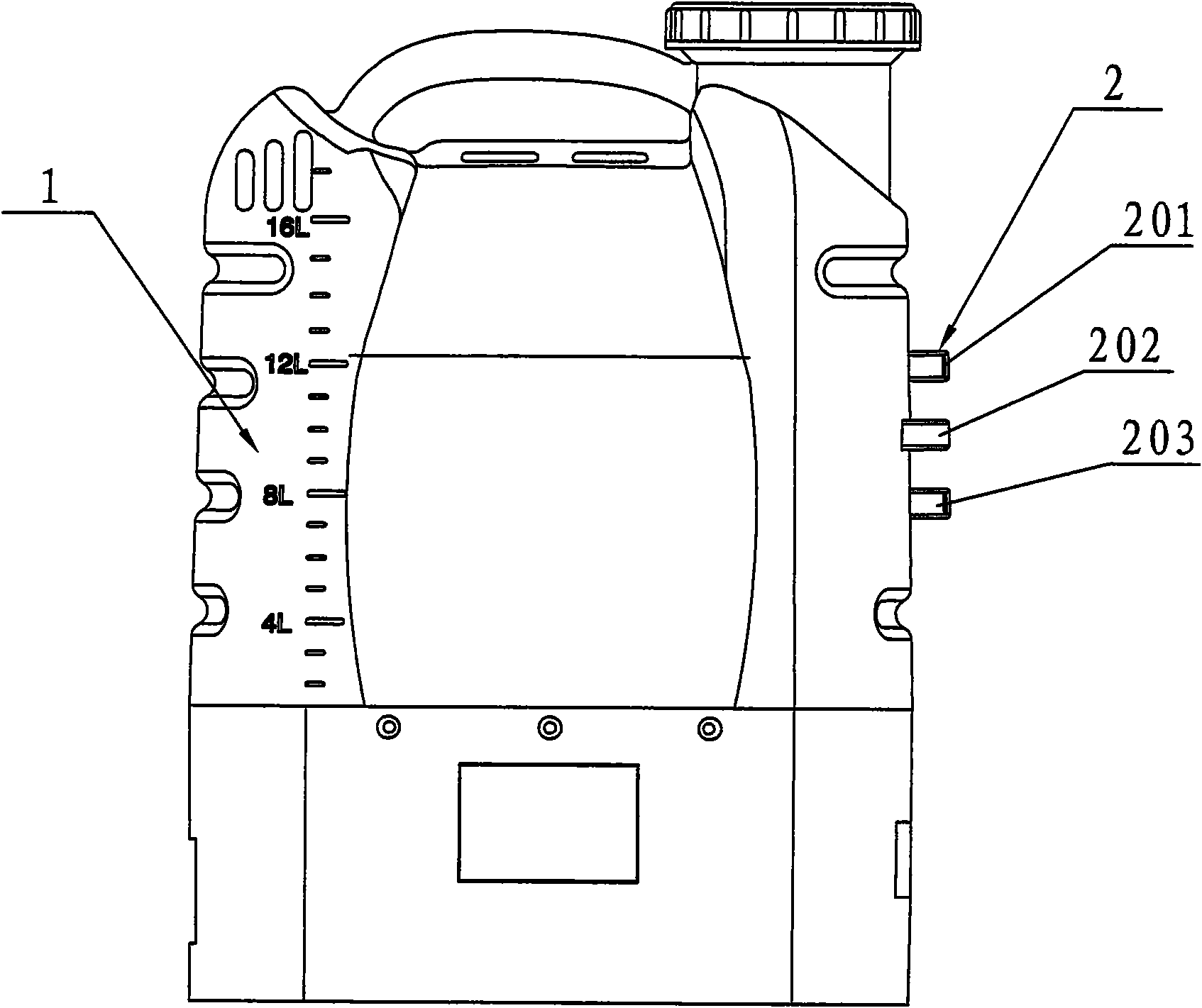

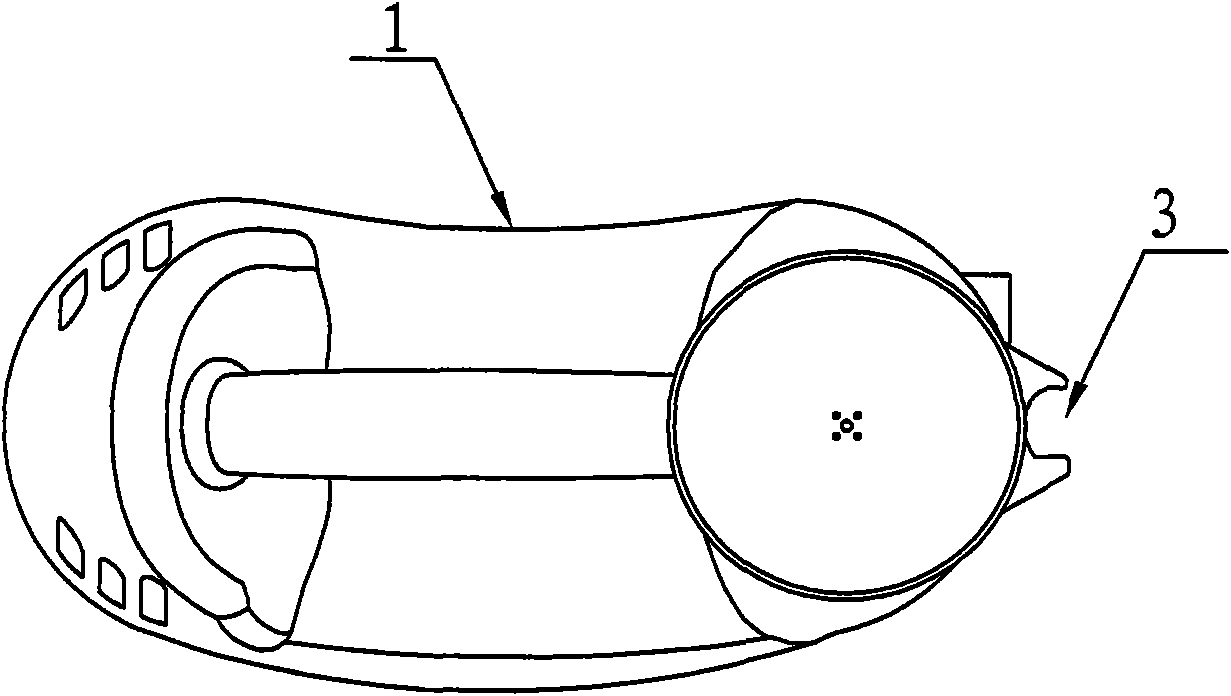

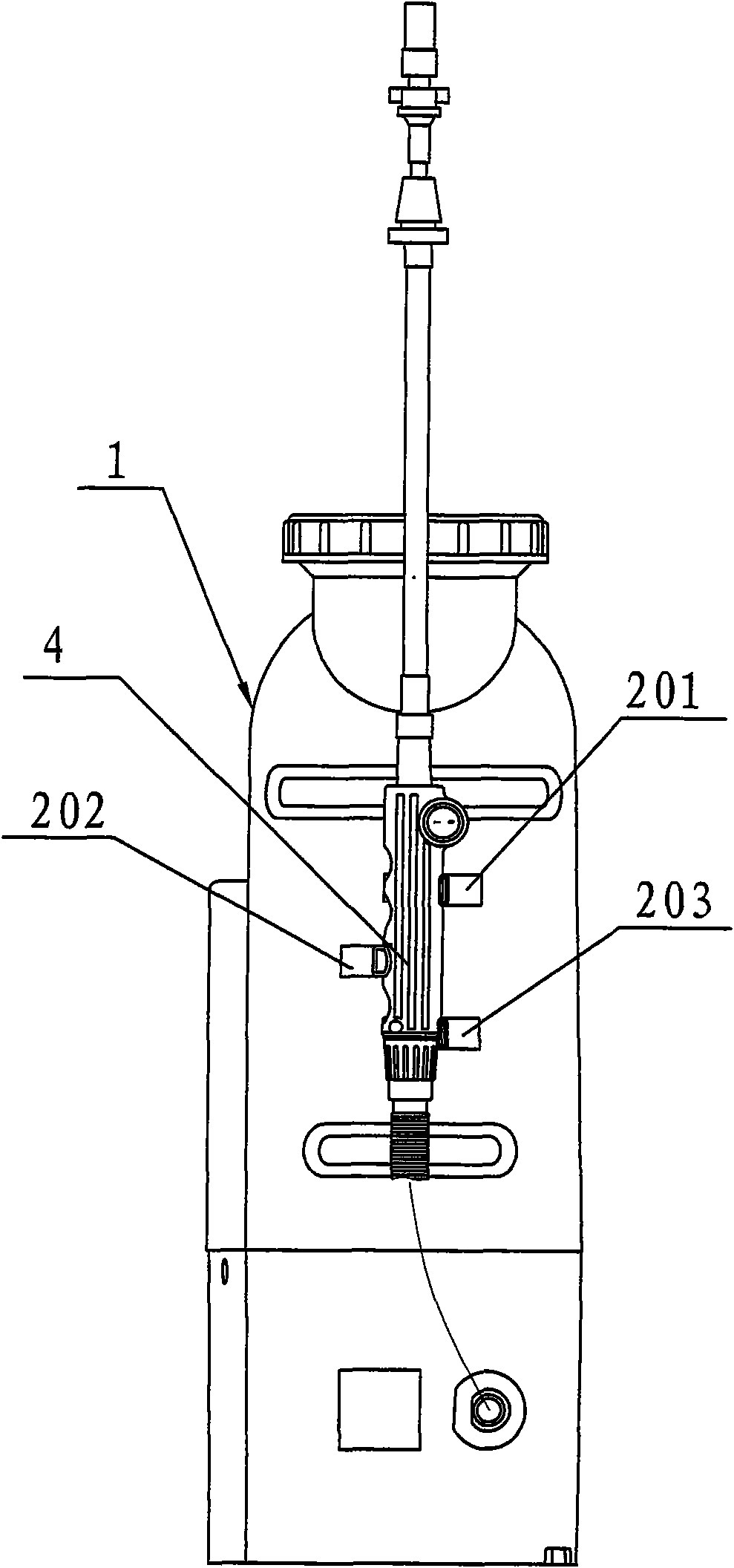

[0017] As attached Figure 1 to 3 The shown sprayer liquid medicine barrel includes a barrel body 1 with clamping blocks 2 protruding from the barrel body 1, and the inner side walls of a plurality of clamping blocks 2 form a cavity for fixing the handle 4 of the spray gun. In the cavity 3, the clamping block 2 and the barrel 1 are integrally formed.

[0018] When the spray gun handle 4 needs to be fixed on the barrel 1 after the sprayer is used, it is only necessary to embed the spray gun handle 4 in the cavity 3 formed by the multiple clamping blocks 2. Since the plurality of clamping blocks 2 and the barrel body 1 are integrally formed, the connection cracks that easily occur between the clamping block inserts and the barrel body in the prior art are eliminated, and compared with the prior art, it is fundamentally solved Leakage of liquid m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap