Touch flat-panel display

一种平板显示器、触控的技术,应用在静态指示器、仪器、电数字数据处理等方向,能够解决影响被触电极判断等问题,达到提高准确性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

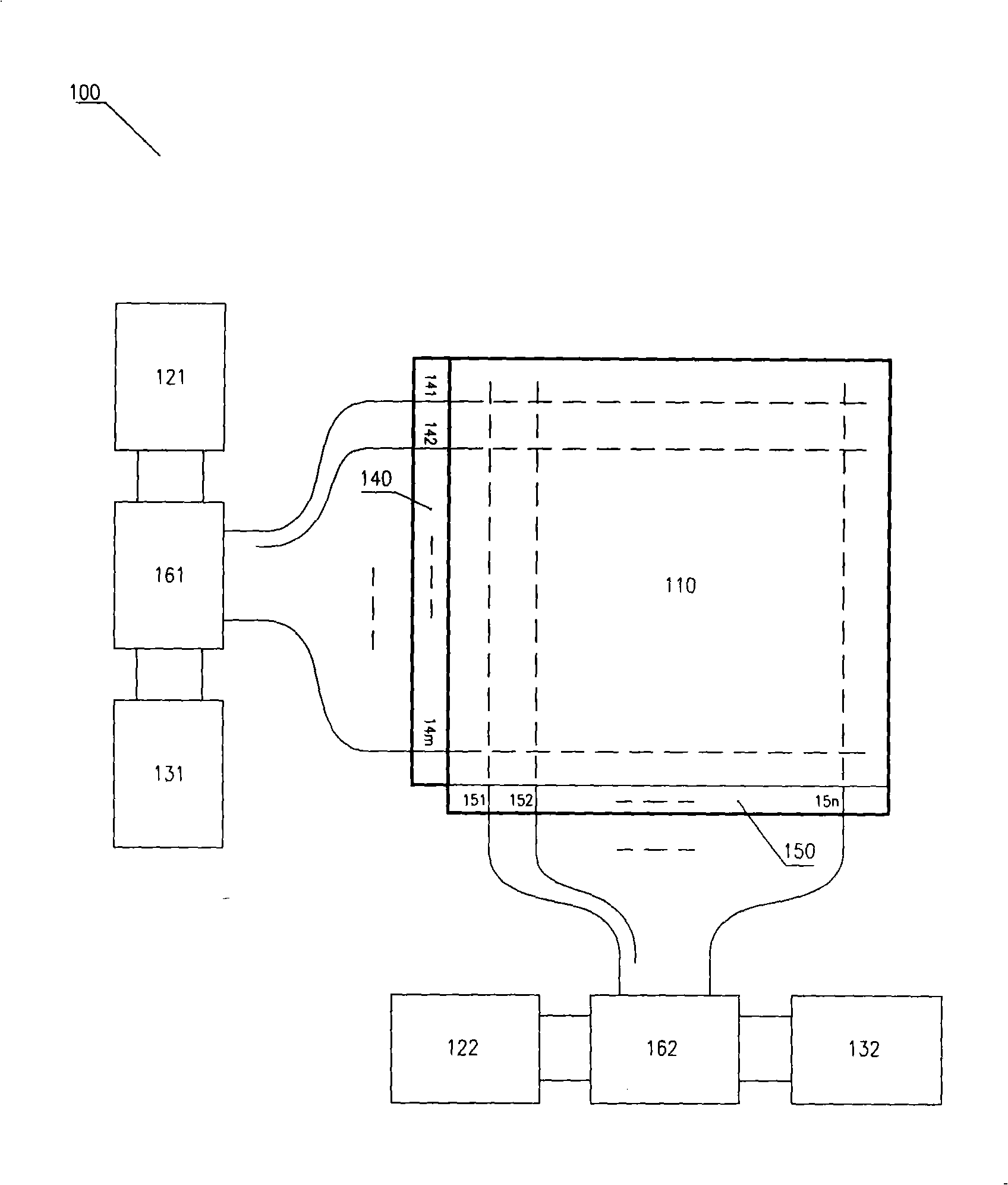

[0038] Such as figure 1 The shown touch panel display 100 includes a passive display screen 110, a display row driving circuit 121 and a display column driving circuit 122, a touch row detection circuit 131 and a touch column detection circuit 132, a row gating circuit 161 and a column gating circuit 162 and so on. The display screen 110 has a row electrode group 140 (with row electrode lines 141, 142, . . . , 14m), and a column electrode group 150 (with column electrode lines 151, 152, . . . , 15n). The row electrode group 140 of the display screen 110 is connected to both the display row driver circuit 121 and the touch row detection circuit 131 , and the column electrode group 150 is connected to both the display row driver circuit 122 and the touch row detection circuit 132 . The row gating circuit 161 and the column gating circuit 162 in the touch-sensitive flat panel display make the display screen electrodes communicate with the display driving circuit to transmit disp...

specific Embodiment approach 2

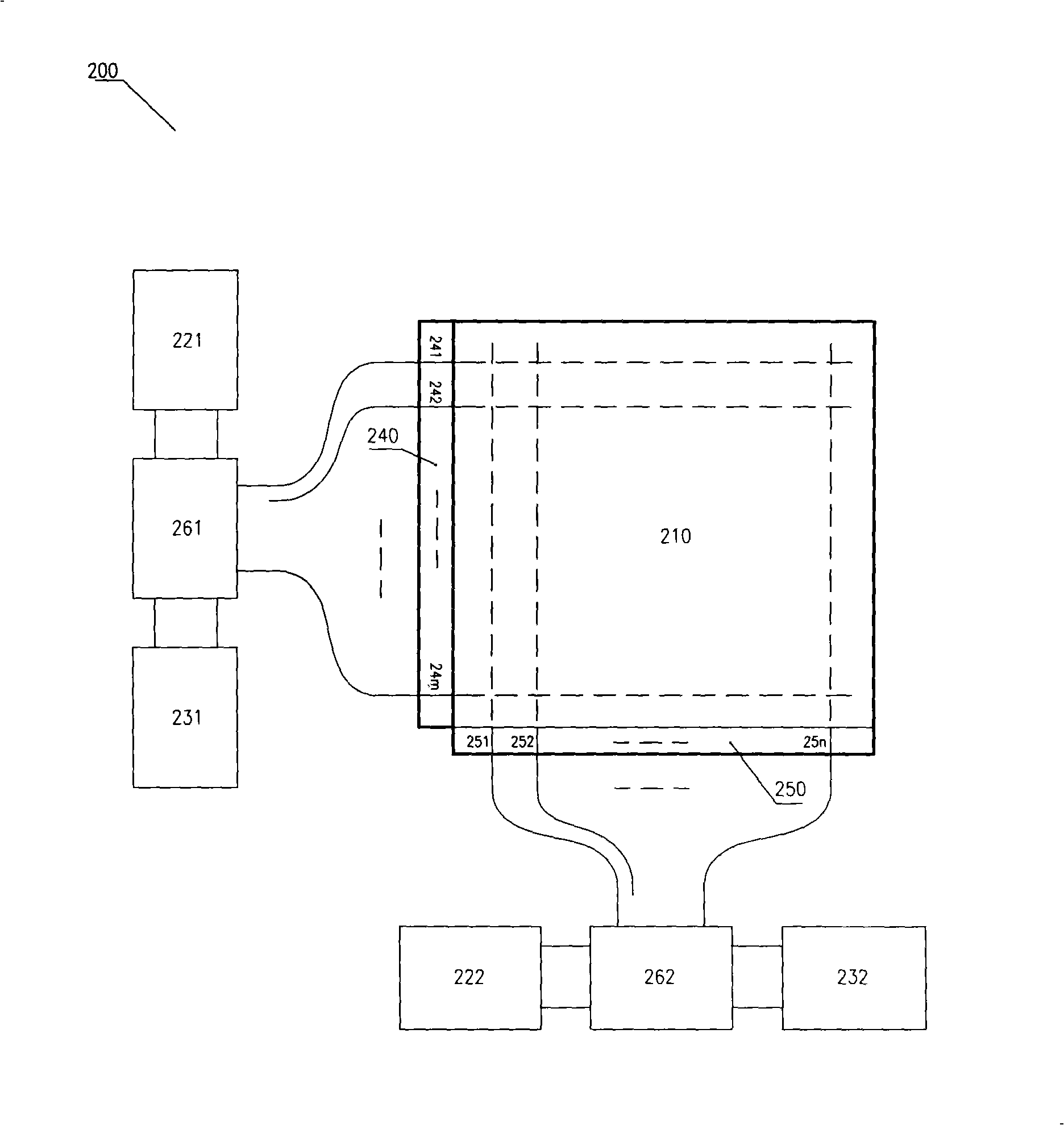

[0046] Such as figure 2 The shown touch panel display 200 includes a passive display screen 210, a display row driving circuit 221 and a display column driving circuit 222, a touch row detection circuit 231 and a touch column detection circuit 232, a row signal loading circuit 261 and a column Signal loading circuit 262 and so on. The display screen 210 has a row electrode group 240 (with row electrode lines 241, 242, . . . , 24m), and a column electrode group 250 (with column electrode lines 251, 252, . . . , 25n). The row electrode group 240 of the display screen 210 is connected to the display row driver circuit 221 and the touch row detection circuit 231 through the row signal loading circuit 261, and the column electrode group 250 is connected to the display column driver circuit 222 and the touch row detection circuit through the column signal loading circuit 262. 232. The signal loading circuit in the touch panel display enables the electrodes of the display screen t...

specific Embodiment approach 3

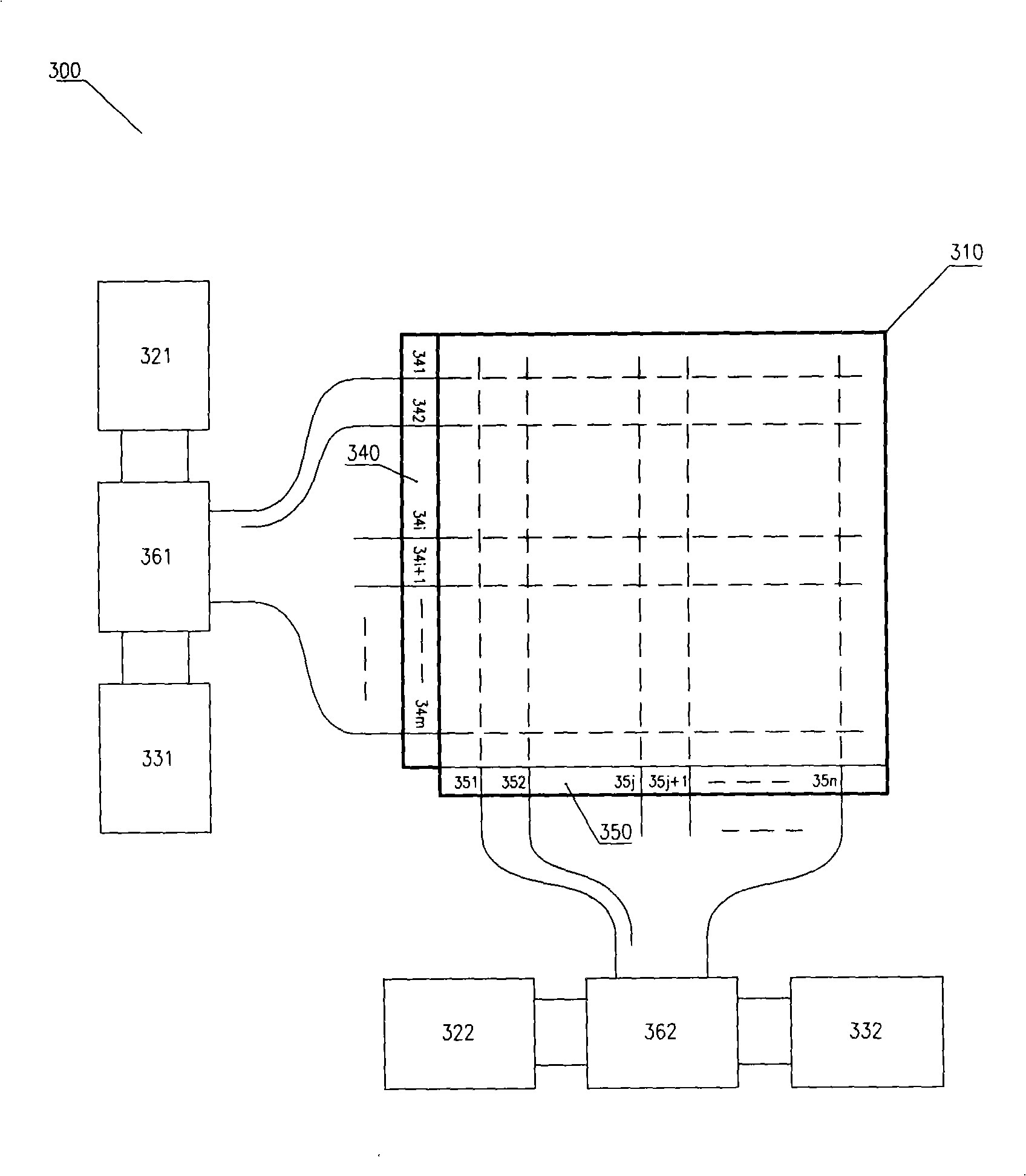

[0052] Such as image 3The shown touch panel display 300 includes a passive display screen 310, a display row driving circuit 321 and a display column driving circuit 322, a touch row detection circuit 331 and a touch column detection circuit 332, a row gating circuit 361 and a column gating circuit 362 and so on. Display screen 310 has row electrode group 340 (with row electrode lines 341, 342, ..., 34i, 34i+1, ..., 34m), and column electrode group 350 (with column electrode lines 351, 352, ..., 35j, 35j+ 1, ..., 35n). The row electrode group 340 of the display screen 310 is connected to both the display row driver circuit 321 and the touch row detection circuit 331 , and the column electrode group 350 is connected to both the display row driver circuit 322 and the touch row detection circuit 332 . The row gating circuit 361 and the column gating circuit 362 in the touch-sensitive flat panel display make the display screen electrodes communicate with the display driving cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com