Use method of outer rotor reluctance motor, optical-mechanical-electrical integrated control system and three-phase alternating current

A reluctance motor and outer rotor technology, applied in the direction of a single motor speed/torque control, electromechanical devices, electrical components, etc., can solve the problem of failure to retrieve the hidden pole outer rotor reluctance motor, not found, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

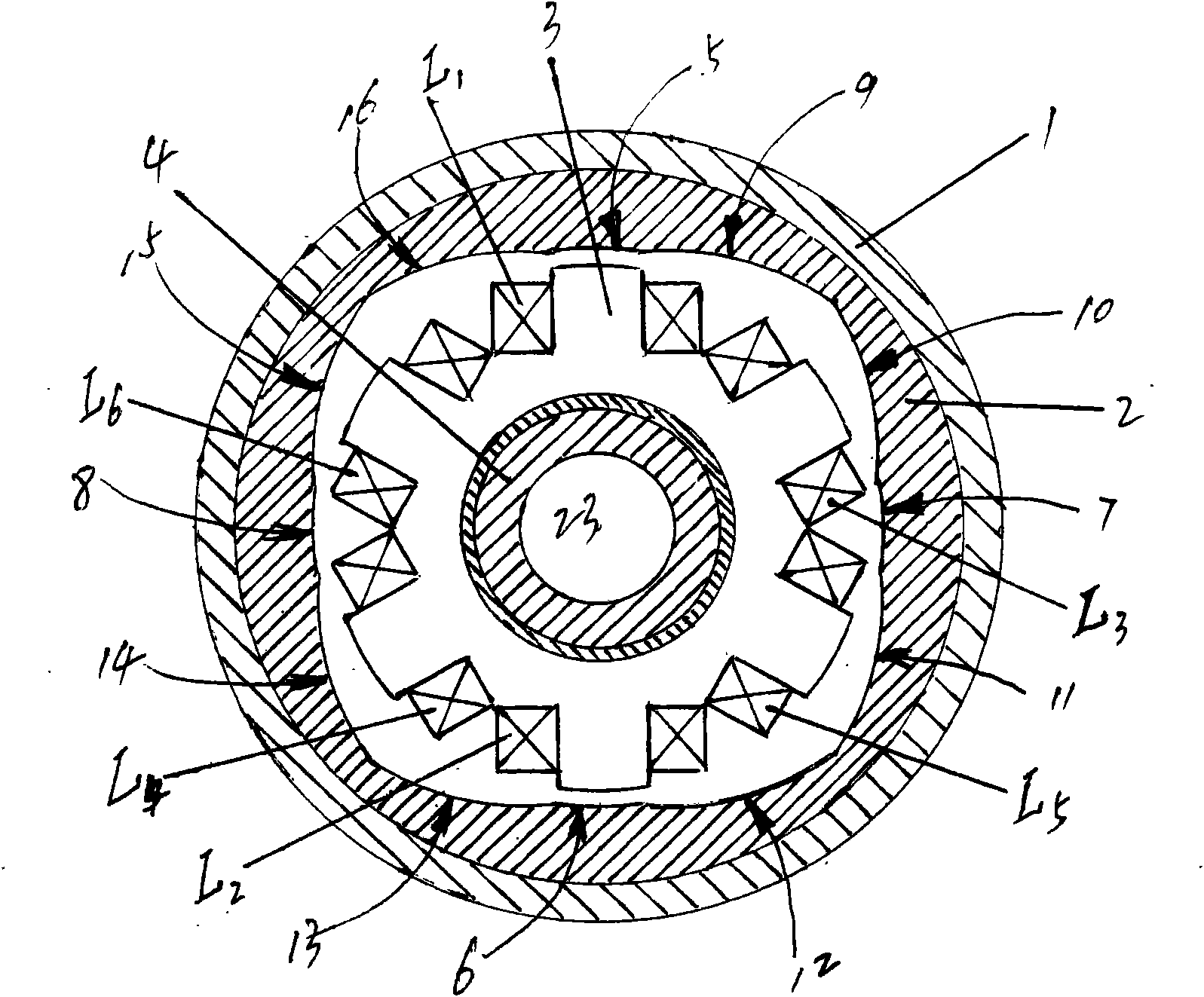

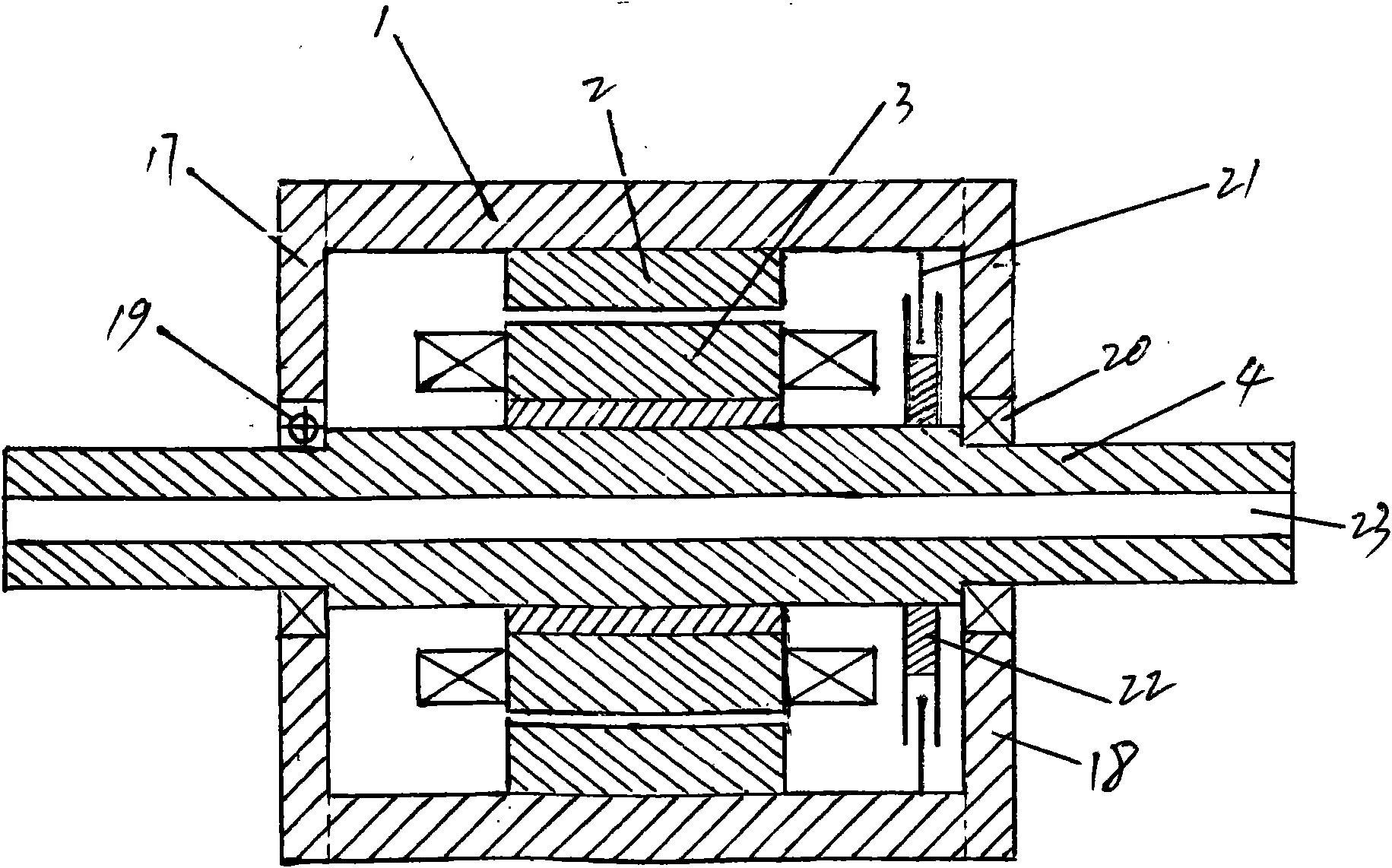

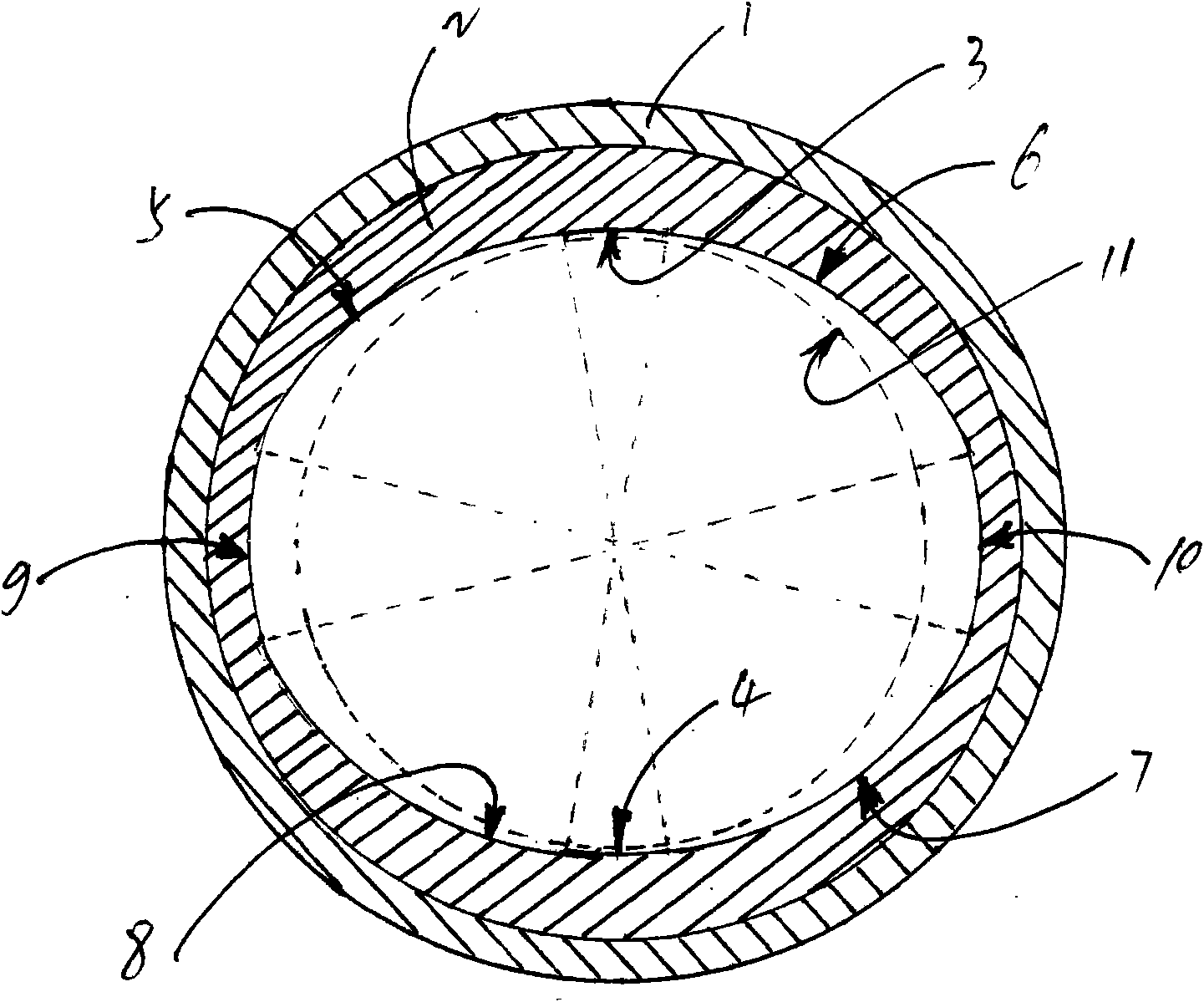

[0027] according to figure 1 , figure 2 As shown, this is an outer rotor reluctance motor with a three-phase 6 / 4 pole stator and rotor structure, and its stator core 3 contains six magnetic poles, which are distributed equidistantly on the circumference. The right-angle dedendum width of each stator magnetic pole is equal to the opening of the six magnetic poles on the circumference of 12 equally divided angles. A simple concentrated winding is installed on each stator pole, and the windings on the two radially opposite stator poles are connected in series or in parallel to form the same phase. That is: the L 1 and L 2 Form A phase, L 3 and L 4 Form C phase, L 5 and L 6 Phase B is formed, and then two pairs of concentric inner arc surfaces (5, 6 and 7, 8) that are radially opposite, have the same radius, are equal in arc width to the stator pole surface, and have a diameter slightly larger than the maximum diameter of the stator pole, respectively Through a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com