Ohmic electrode structure and semiconductor element

An electrode structure, semiconductor technology, applied in the direction of semiconductor devices, electrical components, electrical solid devices, etc., can solve the problems of increased stress of the semiconductor layer 62, deterioration of device characteristics, etc., to reduce resistance, improve potential barrier performance, The effect of suppressing poor wire bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

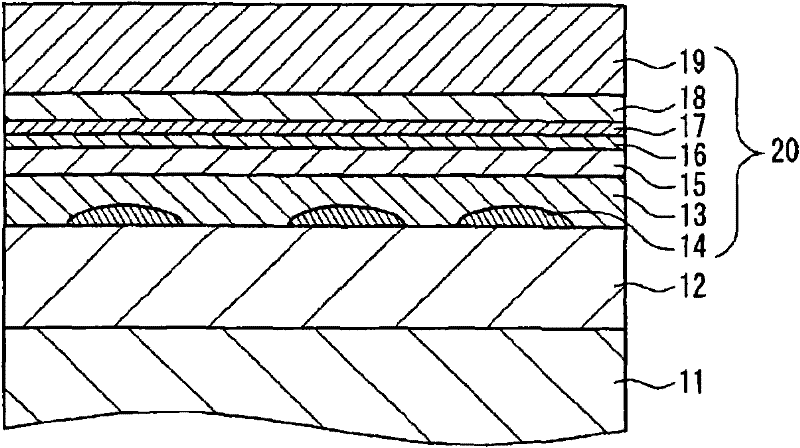

[0078] figure 1 It is a cross-sectional view schematically showing the electrode structure formed on the semiconductor layer in Embodiment 1 of the present invention. This electrode structure has an n-type GaAs contact layer (n-type semiconductor layer) 12 and an electrode metal layer (electrode) 20 formed on the n-type semiconductor layer. In this embodiment, an n-type electrode will be described as an example.

[0079] exist figure 1 In this example, on the n-type GaAs substrate 11, the n-type semiconductor layer 12 is formed as a contact layer with the electrode metal layer 20. An AuGeNi alloy layer 13 is formed on the n-type semiconductor layer 12 , and Ni14 is contained in the AuGeNi alloy layer 13 . On the AuGeNi alloy layer 13, the first Ti layer 15 is formed as the bonding metal layer of the first period. On the first Ti layer 15, the first Pt layer 16 is formed as a barrier metal layer of the first period. On the first Pt layer 16, a second Ti layer 17 is forme...

Embodiment approach 2

[0103] In the semiconductor element according to Embodiment 2 of the present invention, electrodes are formed on both the front surface and the back surface of the semiconductor element. As a semiconductor element having such a structure, there is, for example, a two-wavelength semiconductor laser device. Hereinafter, a dual-wavelength semiconductor laser device will be taken as an example for specific description.

[0104] Figure 5 It is a perspective view of the two-wavelength semiconductor laser device according to this embodiment seen from above. In the dual-wavelength semiconductor laser device according to this embodiment, a red semiconductor laser 1 having an oscillation wavelength in the 660 nm band and an infrared semiconductor laser 2 having an oscillation wavelength in the 780 nm band are formed on the same substrate.

[0105] Such as Figure 5 As shown, in the two-wavelength semiconductor laser device of this embodiment, a red semiconductor laser 1 and an infra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com