Double-fan-blade coupling type wind energy generating set

A technology of generating sets and generators, which is applied in the direction of wind power generation, wind power motor combination, wind power engine, etc., and can solve the problem of poor application and promotion of wind power generators, difficult technical problems of wind power generators, and difficulty in starting and outputting power of wind power generators And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

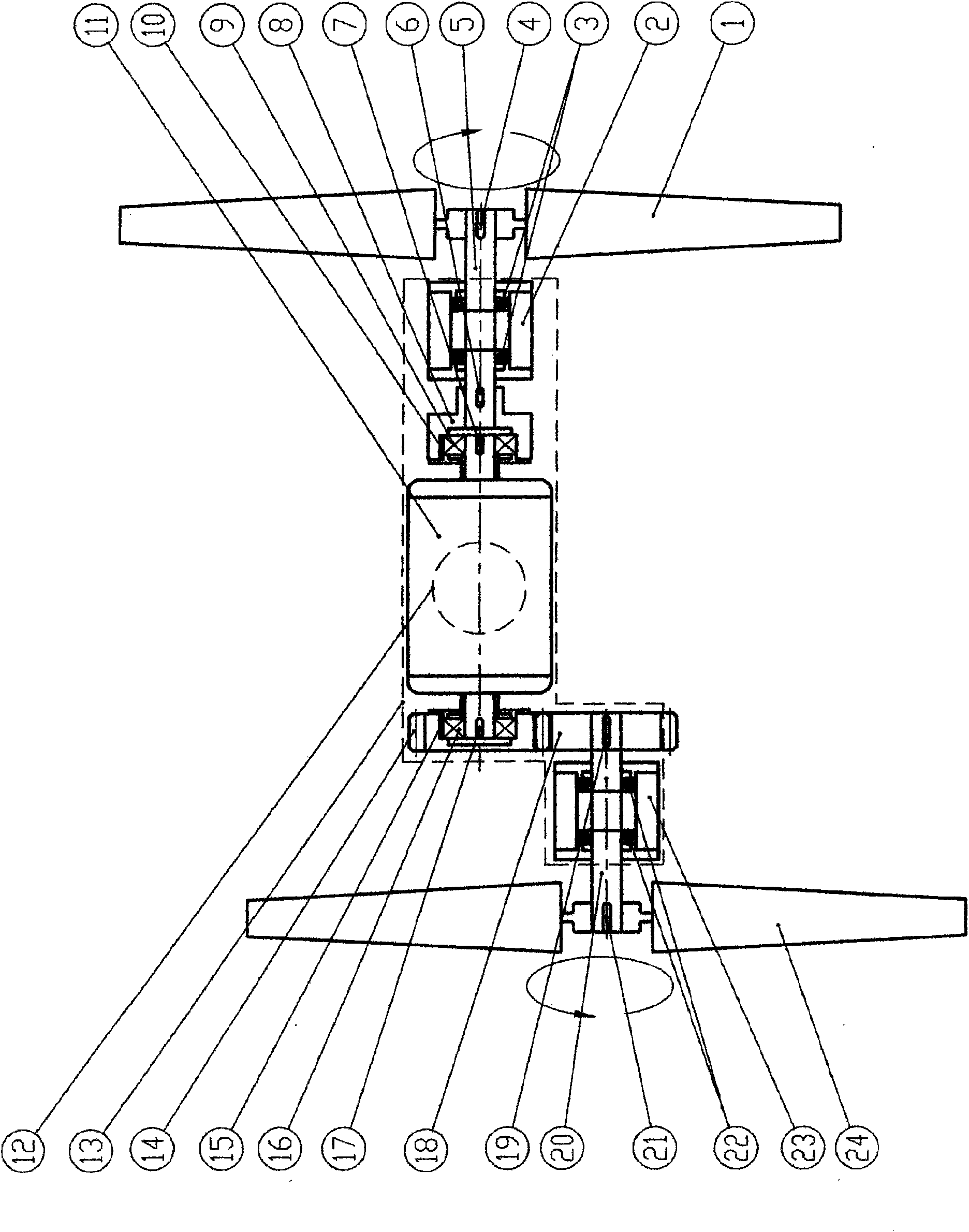

[0009] see figure 1 : the present invention's double-blade connecting-shaft wind energy generating set comprises base 13, forward-rotating wind blade 1, reverse wind blade 24, main shaft 5, one-way bearing 9, shaft coupling 8, reverse wind blade 24, main shaft 20, single To bearing 16, generator 11.

[0010] The forward-rotating fan blade 1 is connected to one end of the main shaft 5 through the shaft pin 4. The bearing 3 is installed in the middle of the main shaft 5. The bearing 3 is installed in the bearing seat 2. The coupling 8 is connected to the other end of the main shaft 5 through the shaft pin 6. The outer ring of the bearing 9 is connected with the inner hole of the shaft coupling through the shaft pin 10, and the inner ring of the one-way bearing 9 is installed on one end of the generator 11 shaft through the shaft pin 7.

[0011] The reversing vane 24 is connected to one end of the main shaft 20 through the shaft pin 21, the bearing 22 is installed in the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com