Method and system for measuring aspiratory flow velocity by differential pressure type sensor

A sensor and differential pressure technology, which is applied in the field of measuring inspiratory flow rate using a differential pressure sensor, can solve the problems of weak output signal, complicated implementation, and narrowed measurement range, so as to reduce inspiratory resistance and be simple and easy to implement , reducing the effect of breathing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in detail below with reference to the accompanying drawings.

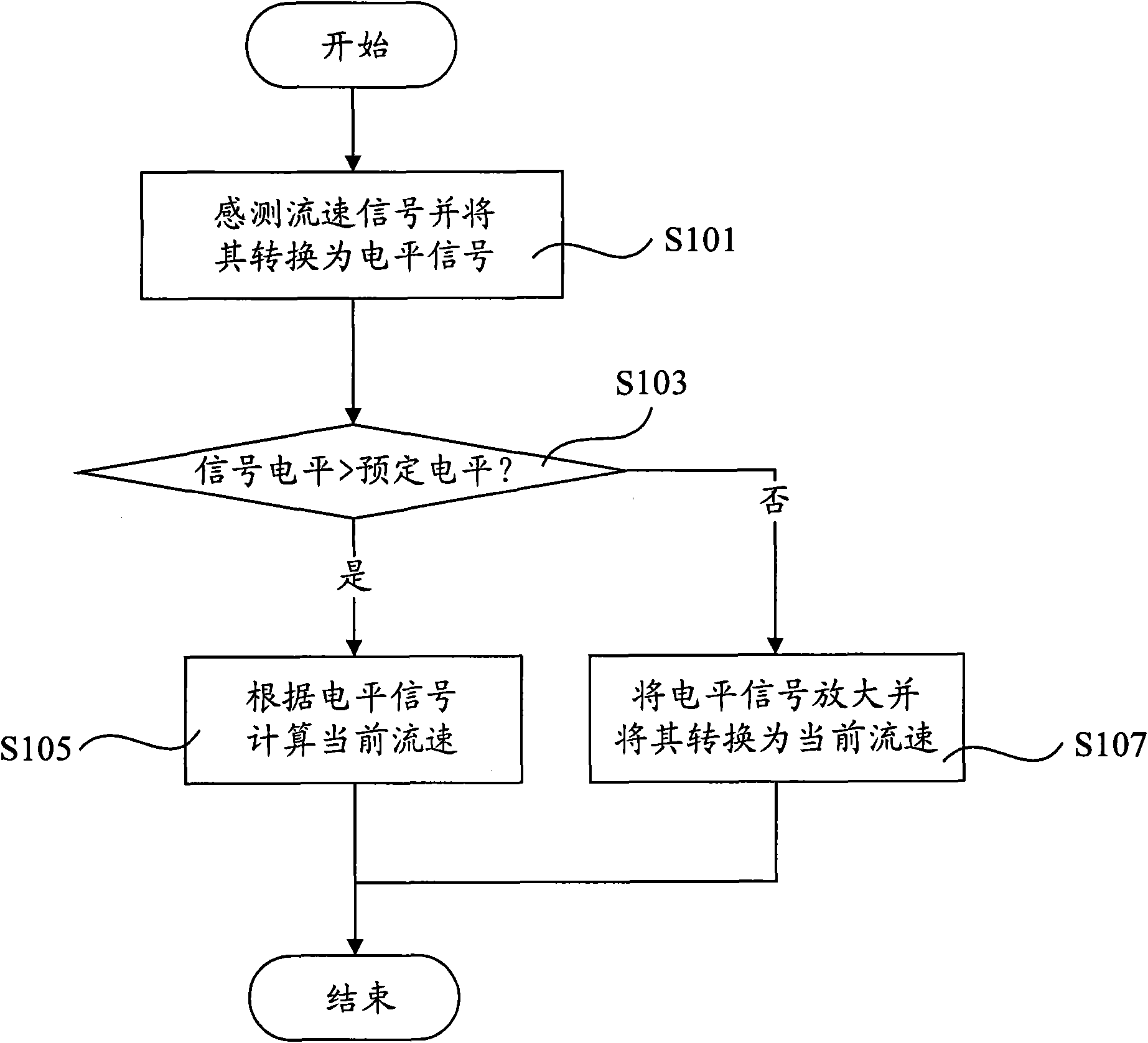

[0016] figure 1 is a flowchart of a method for measuring an inspiratory flow rate according to an embodiment of the present invention. Such as figure 1 As shown, the method includes the following steps:

[0017] Sensing the flow velocity signal and converting it into a level signal (S101);

[0018] Comparing the level signal with a predetermined level (S103); and

[0019] If the level signal is greater than the predetermined level, calculate the current flow rate according to the level signal (S105), and if the level signal is less than the predetermined level, amplify the level signal and calculate according to the amplified level signal current flow rate (S107);

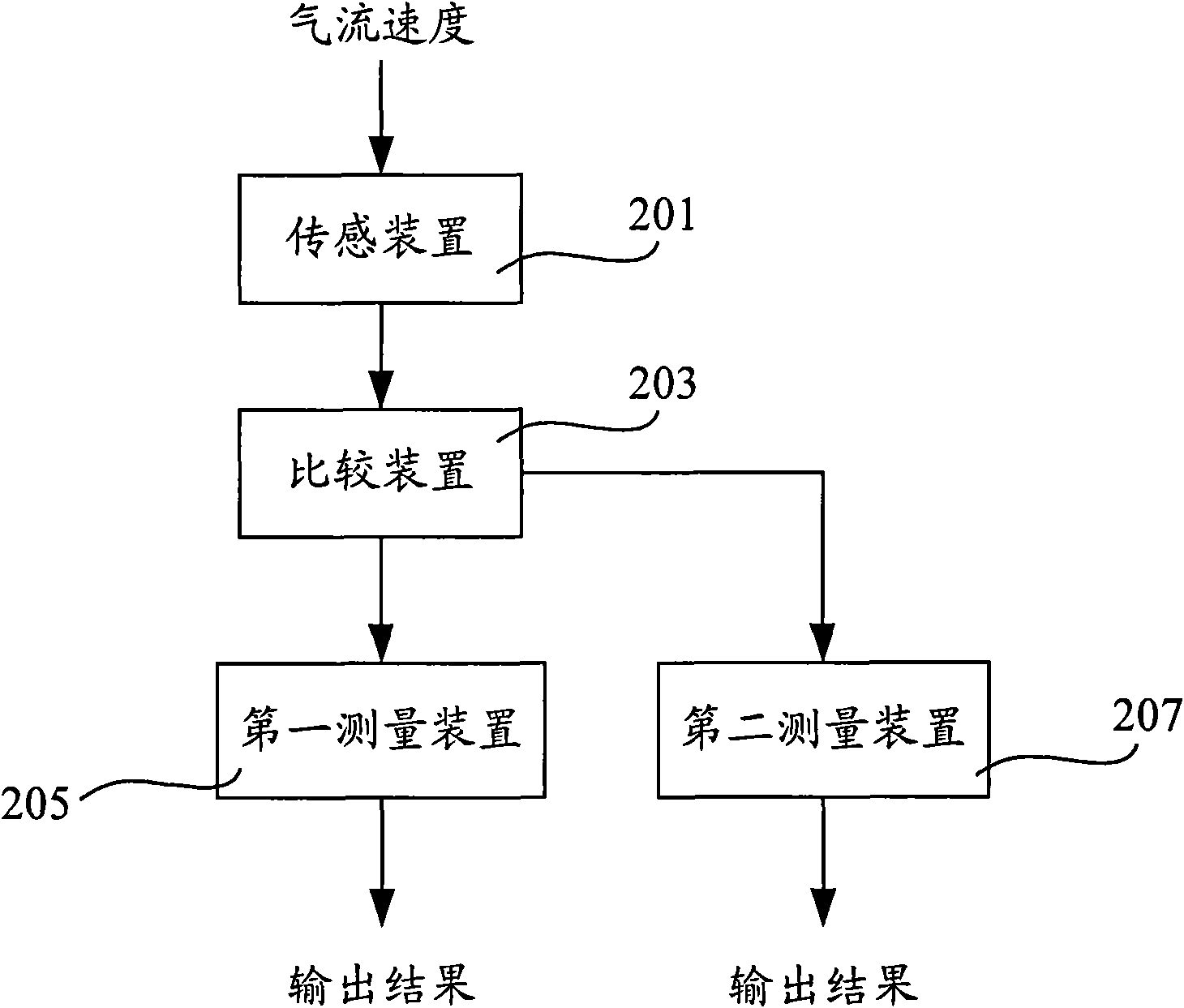

[0020] figure 2 is a block diagram of a system for measuring respiratory flow rate according to an embodiment of the present invention. Such as figure 2 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com