Macromolecular deodorizer and preparation process thereof

A deodorant and polymer technology, applied in the field of polymer deodorant and its preparation process, can solve the problems of incompatibility and discount of deodorant effect, and achieve the effect of simple processing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

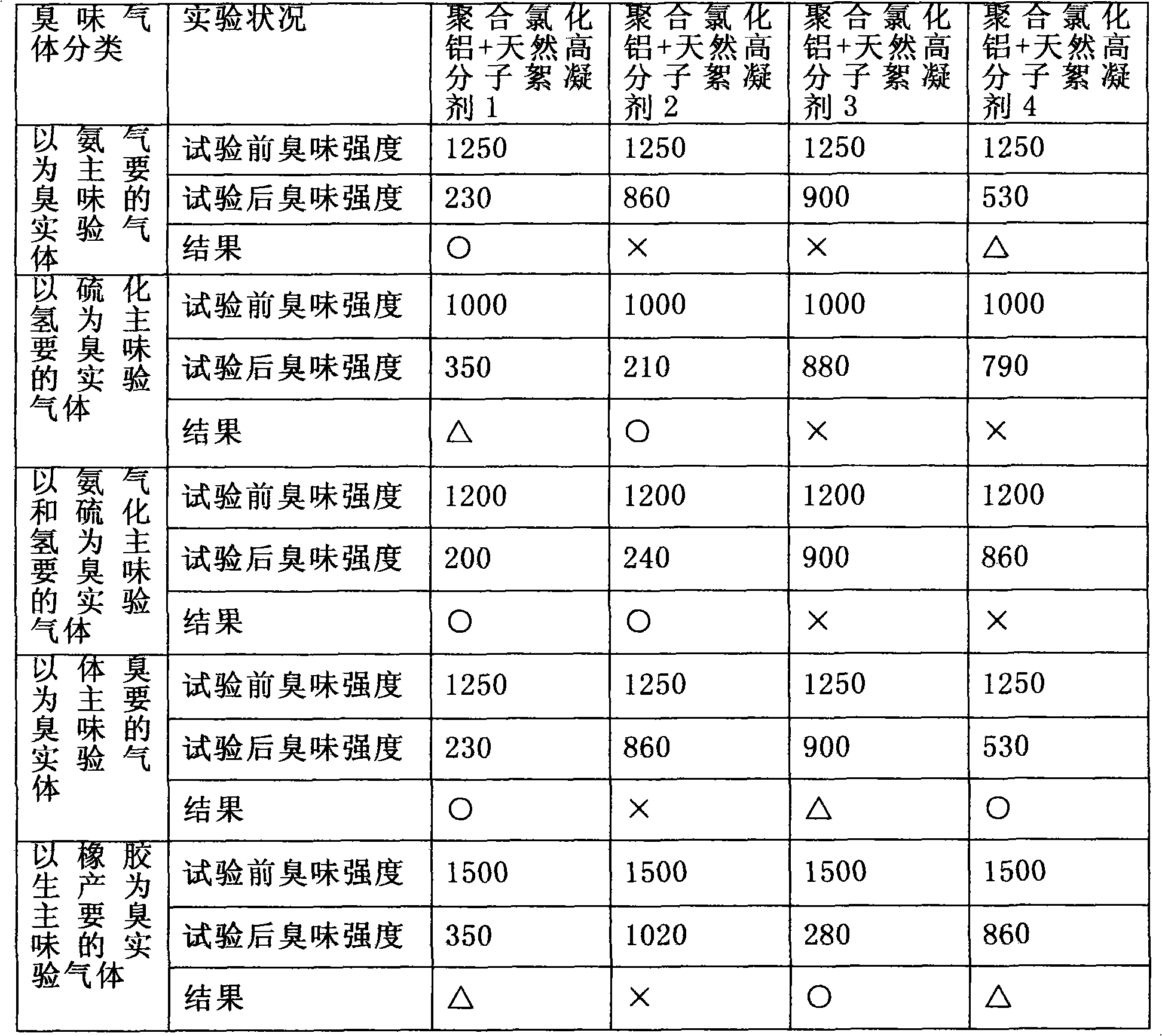

Image

Examples

Embodiment 1

[0031] A polymer deodorant, the preparation process is as follows:

[0032] 1. Take 10 parts of inorganic polymer coagulant and add it to 100 parts of water. Stir continuously during the addition process so that no fish-eye flocs are produced. In order to dissolve thoroughly, the water can be properly warmed. Prepare an inorganic polymer coagulant solution.

[0033] 2. Take 7 parts of natural polymer coagulant and add it to 100 parts of water. Stir continuously during the addition process so that no fish-eye flocs are produced. In order to dissolve thoroughly, the water can be properly warmed. Made of natural polymer coagulant solution.

[0034] 3. Dissolve 3 parts of defoaming agent in 50 parts of water, take 5 parts of its aqueous solution and add it into the natural polymer coagulant solution. Be careful to stir constantly while adding.

[0035] 4. Mix the above two polymer coagulant solutions. Note that when mixing, slowly add the prepared inorganic polymer coagula...

Embodiment 2

[0086] A polymer deodorant, comprising the following raw materials in parts by weight:

[0087] Inorganic polymer coagulant 5 Natural polymer coagulant 10

[0088] Defoamer 1 Antimicrobial 1.5

[0089] Bactericide 0.5.

[0090] The production process is the same as the preparation process of Example 1.

Embodiment 3

[0092] A polymer deodorant, comprising the following raw materials in parts by weight:

[0093] Inorganic polymer coagulant 15 Natural polymer coagulant 5

[0094] Defoamer 5 Antibacterial agent 0.5

[0095] Bactericide 1.5.

[0096] The production process is the same as the preparation process of Example 1.

[0097] Features of dual-media polymer deodorant

[0098] 1. Instantly eliminate odor

[0099] When the odor molecules meet the huge microgel, the strong attraction will firmly attach the odor molecules to the polymer network. Odor molecules can be divided into acidic or alkaline, neutral odor, but regardless of the nature of the odor molecule, the dual-media polymer deodorant can achieve the same effect as activated carbon adsorption to achieve the instant odor elimination effect.

[0100] 2. Positive and negative ion efficiency

[0101] The biggest weapon of ultragel is that the polymer structure has the function of positive and negative zwitterions. Many deodora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com