Regulable wheel wrench

A wrench and wheel technology, applied in the direction of wrenches, manufacturing tools, wrenches, etc., can solve the problems of waste of resources, single specifications, complex material management, etc., and achieve the effect of preventing self-moving, accurate adjustment, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

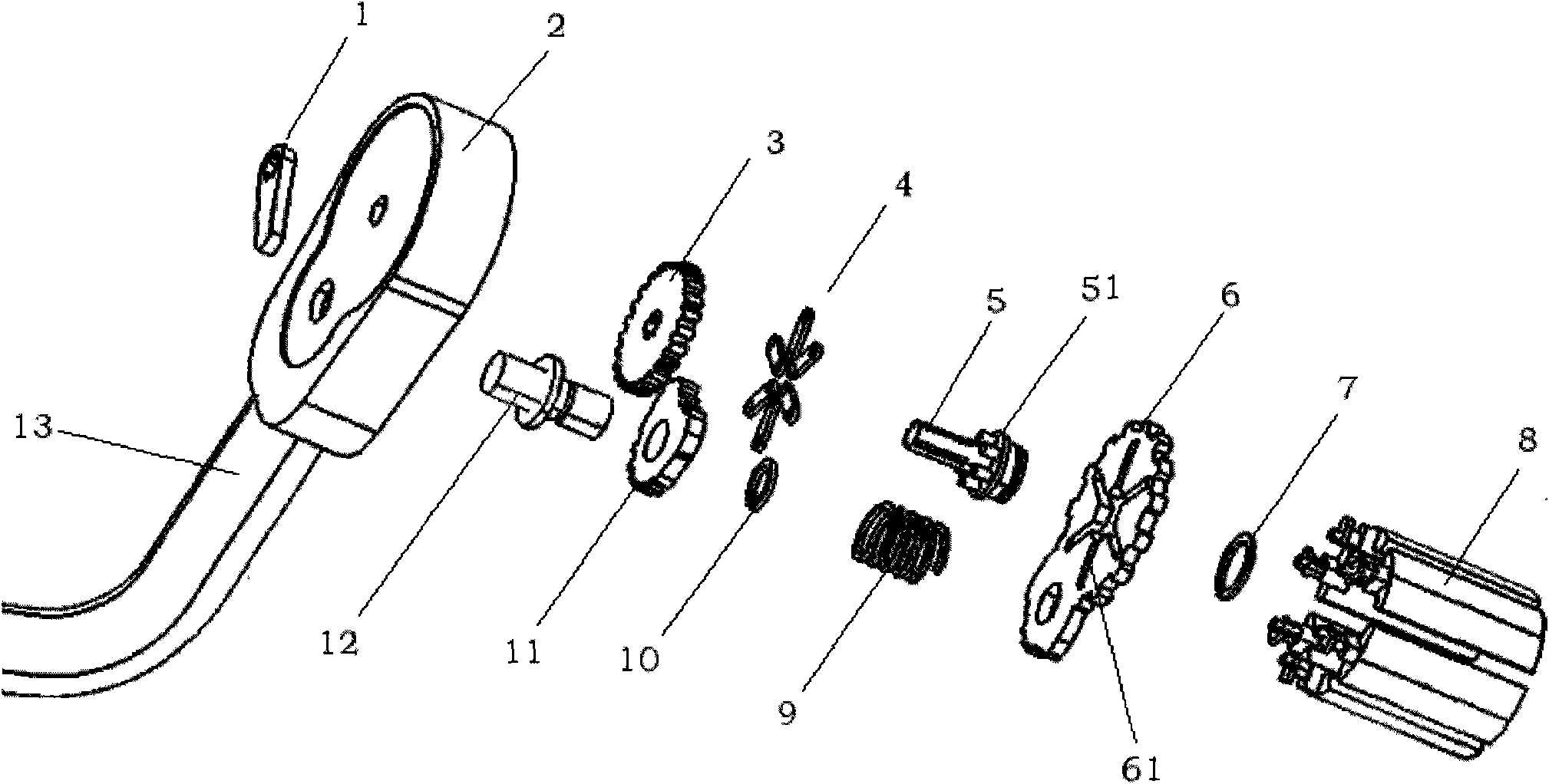

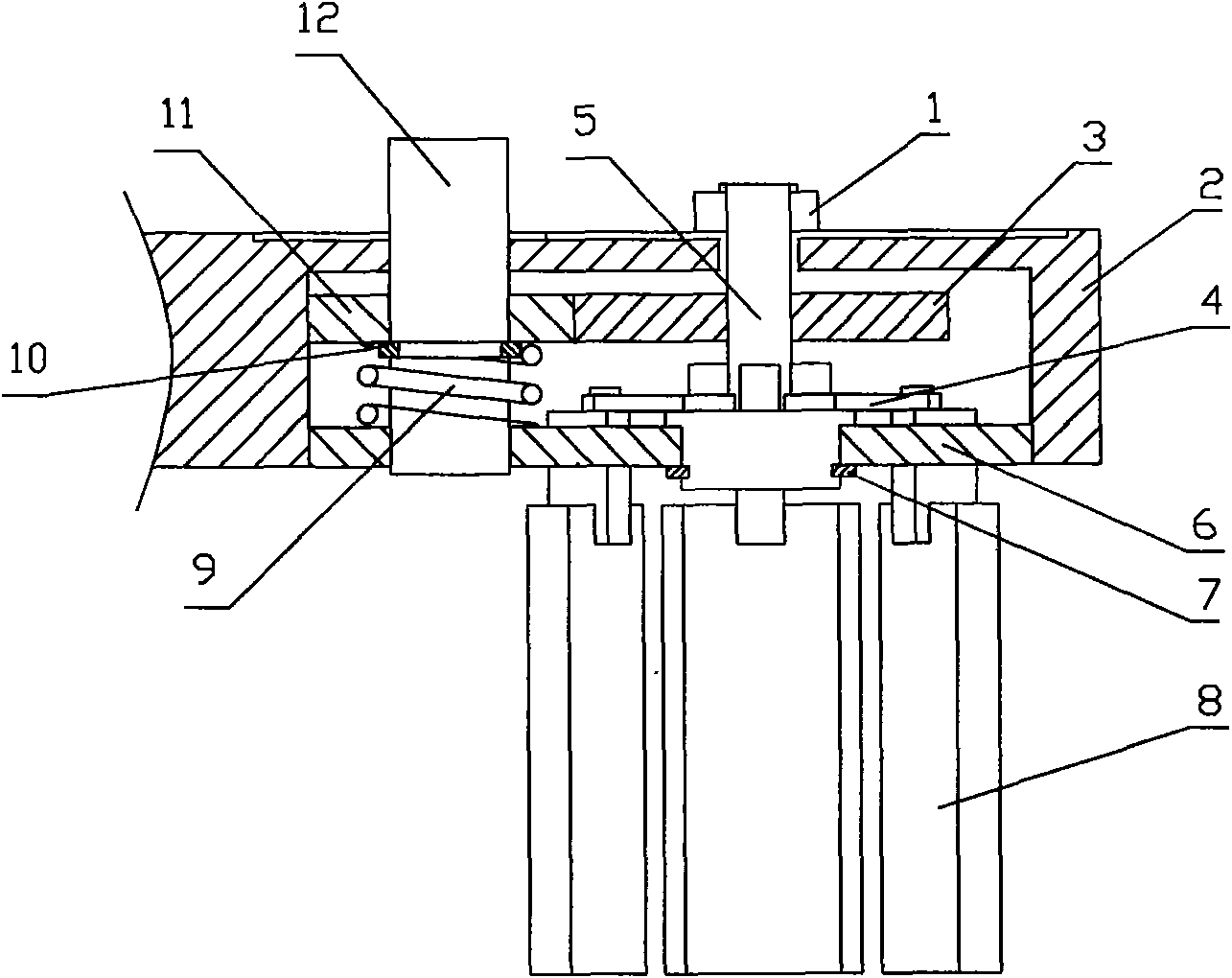

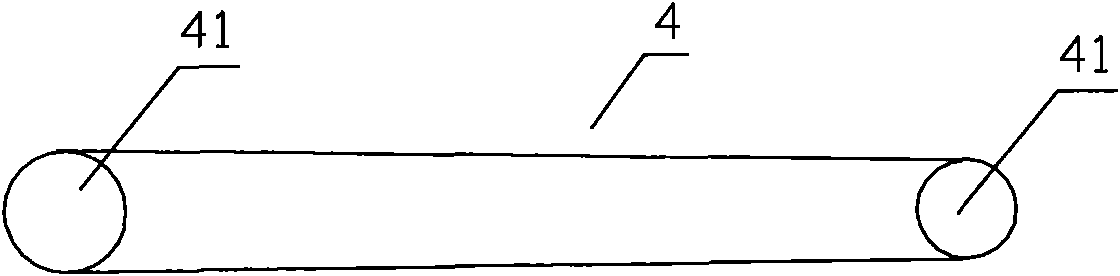

[0022] Such as figure 1 , 2 As shown, the adjustable wheel wrench of the present embodiment includes a wrench body 13 and a plurality of sliders 8 for clamping nuts. The key point is that the wrench also includes an adjustment box 2 fixed at the end of the wrench body 13. The bottom cover 6 of the adjustment box 2 is provided with strip-shaped guide holes 61 arranged radially corresponding to the number of sliders 8, and the sliders 8 are slidably stuck in the guide holes 61; shaft 5, the periphery of the adjustment shaft 5 is provided with an adjustment column 51 in the direction towards each guide hole 61, and the adjustment column 51 is connected with the slider 8 through the connecting rod 4, so as to convert the rotation of the adjustment shaft 5 into The sliding block 8 slides along the guide hole 61; the wrench also includes a locking mechanism, which can lock or allow the adjustment shaft to rotate.

[0023] The top end of the adjustment shaft 5 protrudes from the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com