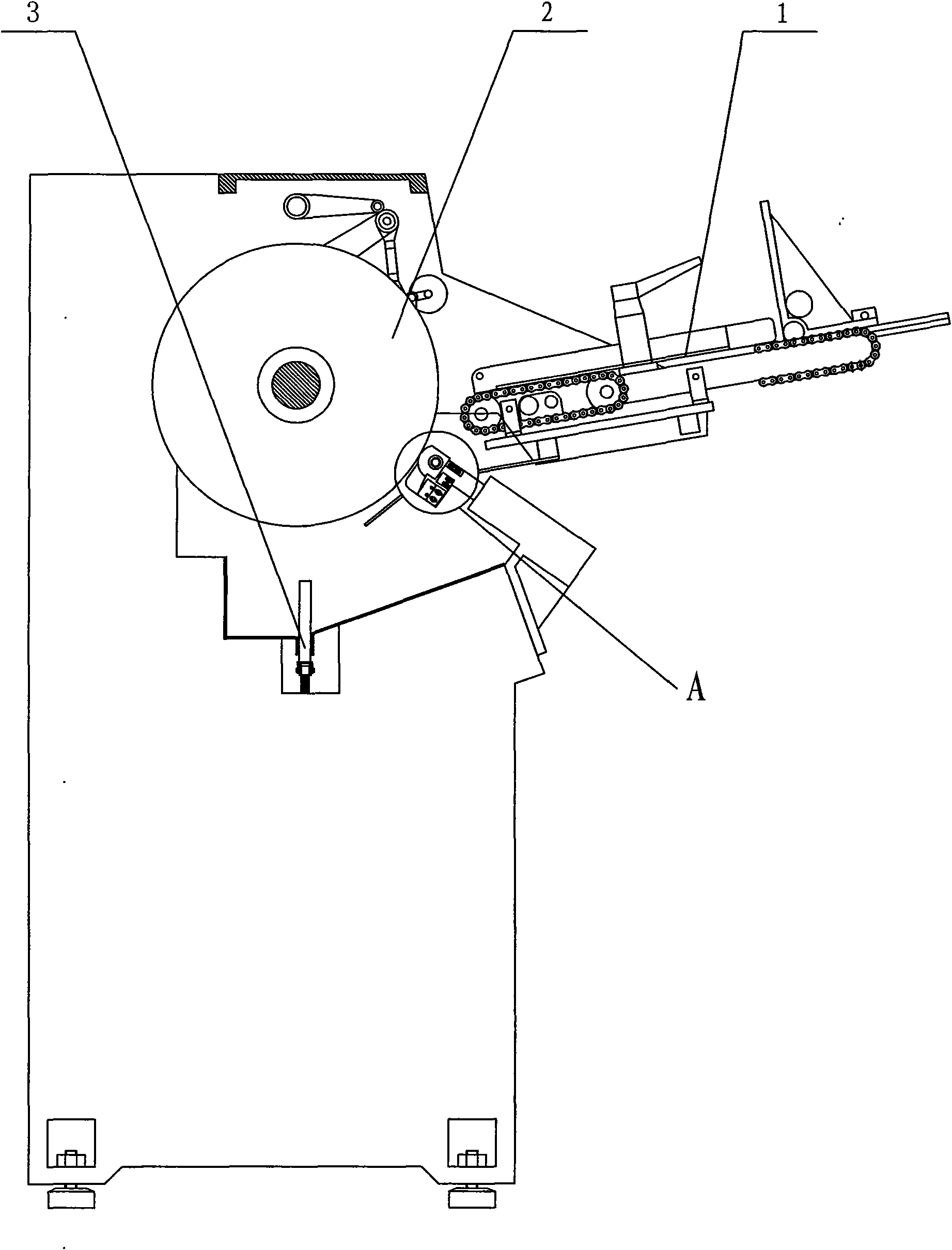

Double-page or multi-page paper sheet detecting device of collating machine

A detection device and collating machine technology, applied in the directions of transportation and packaging, object supply, pile separation, etc., can solve the problems of high cost, complicated operation, and high requirements for paper consistency, and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

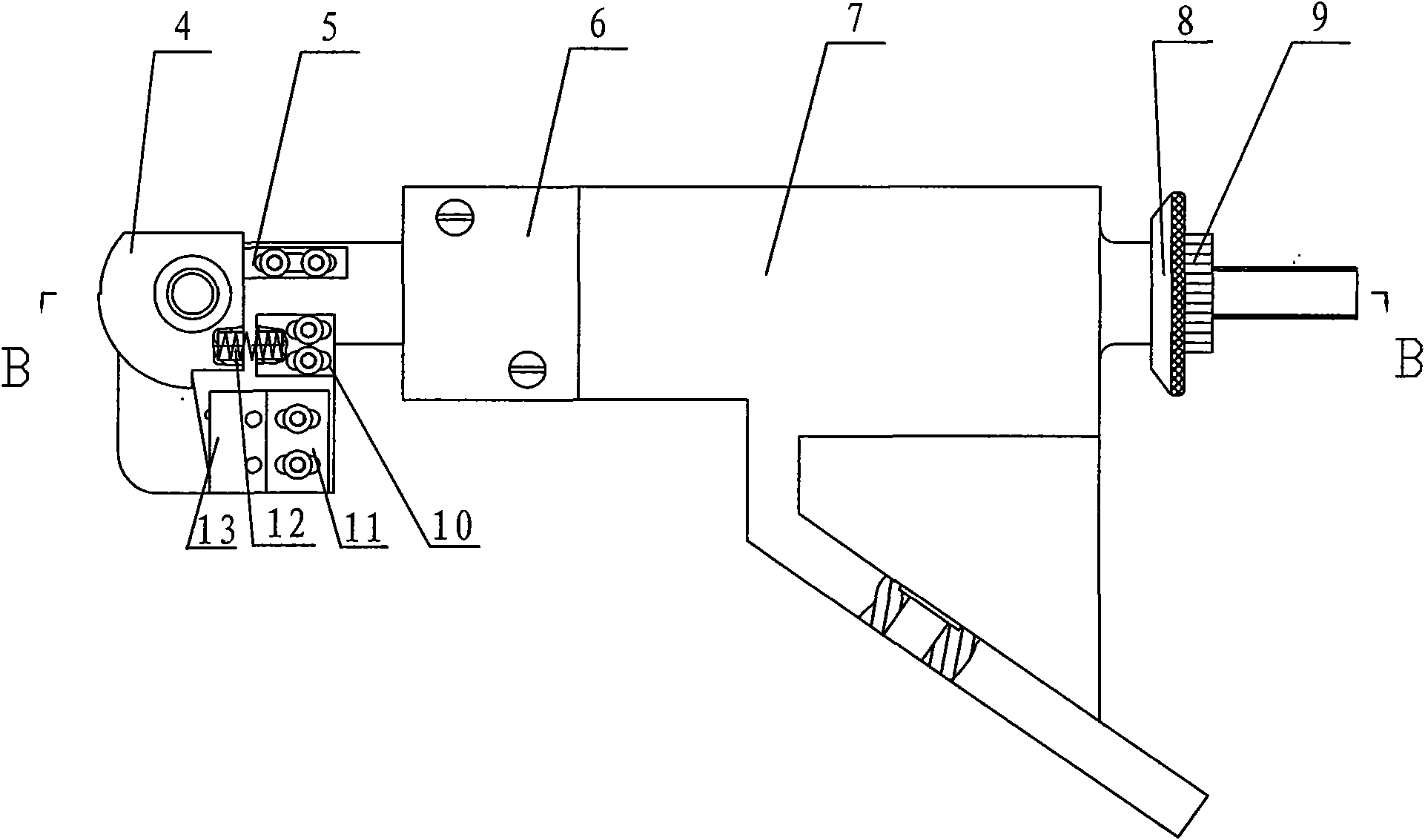

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

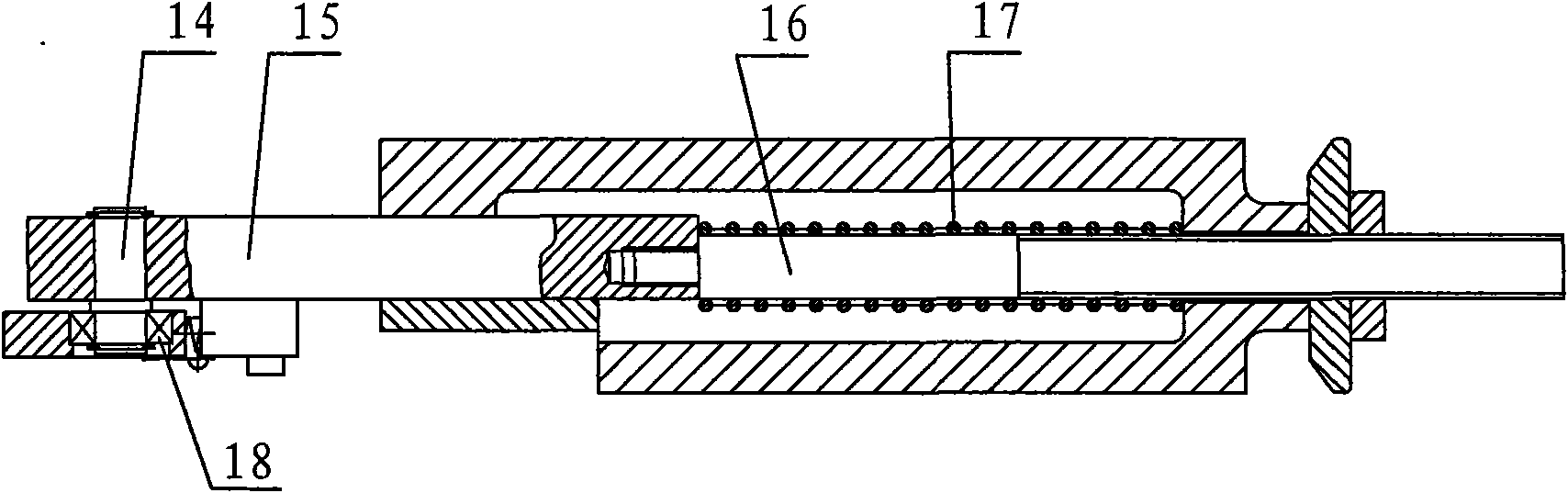

[0017] Such as figure 2 , 3 As shown, the collating machine double or multiple paper page detection device includes an induction mechanism, a connecting plate 15 and a main frame 7, and also includes a wheel mechanism; the wheel mechanism consists of a shaft 14, a bearing 18, a spring 12, and a spring seat 10. Its front profile is matched with the outer circle of the gripper cylinder 19 of the collating machine and the runner 4 is formed with a gap; the shaft 14 is fixed on the connecting plate 15, the inner ring of the bearing 18 is sleeved on the shaft 14, and the runner 4 passes The hole is set on the outer ring of the bearing 18; one end of the spring 12 is in the groove on the rear side of the runner 4, and the other end is in the groove on the front side of the spring seat 10; the spring seat 10 is passed through the spring seat 10 by a screw Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com