Double pulse combined type transformer

A combined transformer and pulse wave technology, applied in the direction of transformers, fixed transformers, transformer/inductor coils/windings/connections, etc., can solve the problems of increased costs of related power distribution facilities, increased floor space, and increased transformer manufacturing costs. , to achieve the effect of ensuring simultaneous or separate operation, reducing the occupied area, and reducing the load loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

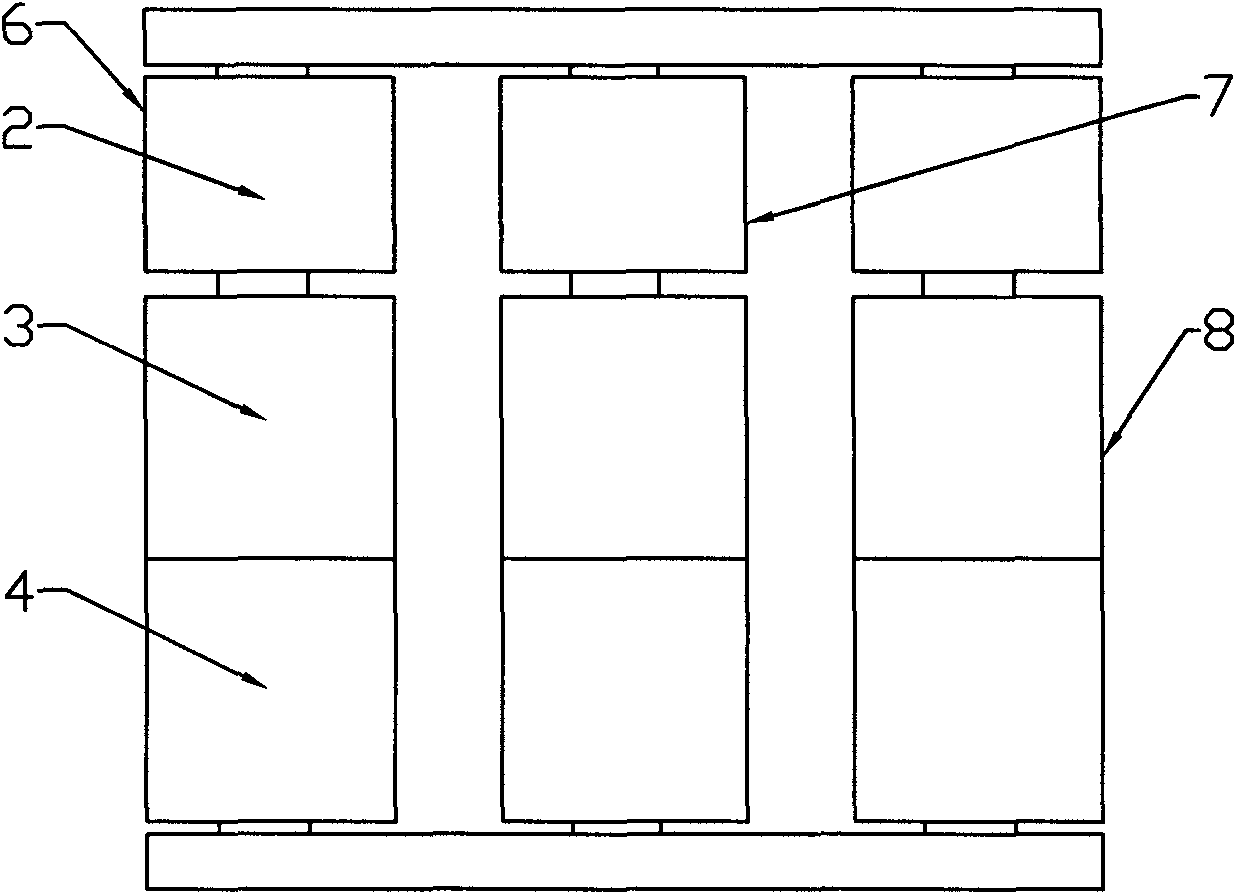

[0009] like figure 1 As shown, this kind of dual-pulse wave combined transformer includes an iron core 1, a coil and a support frame 5. The coil is three-phase, that is, A phase 6, B phase 7, and C phase 8. Each phase is divided along the axis of the iron core 1. It consists of three parts: upper winding 2, middle winding 3 and lower winding 4. The spacing between the upper winding 2 and the middle winding 3 is greater than one-third of the axial height of the upper winding 2, and the distance between the middle winding 3 and the lower winding 4 is smaller, so that the upper winding 2 and the middle winding 3 are connected by adding The large axial distance between them weakens the magnetic coupling effect between them.

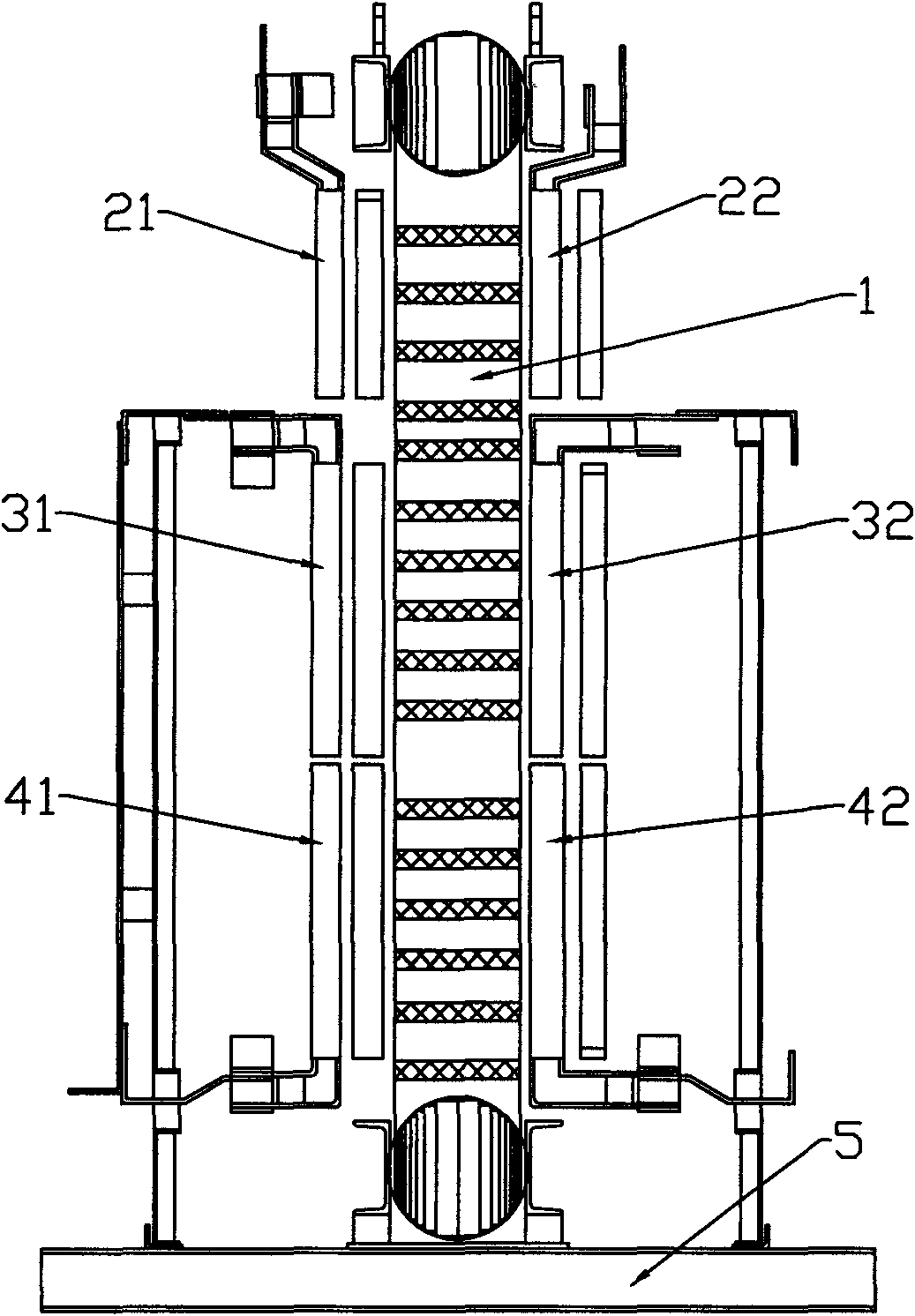

[0010] like figure 2 As shown, there is one primary side coil and one secondary side coil in the upper winding 2, middle winding 3 and lower winding 4 of each phase of the transformer, which are arranged in sections along the axial direction of the iron co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com