Three-dimensional nanometer-grade cutting simulation method based on molecular dynamics

A molecular dynamics, three-dimensional nanotechnology, applied in the fields of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of measurement and calculation limit, no research report on 3D tool simulation model, etc., to achieve effective cutting. the effect of the result

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

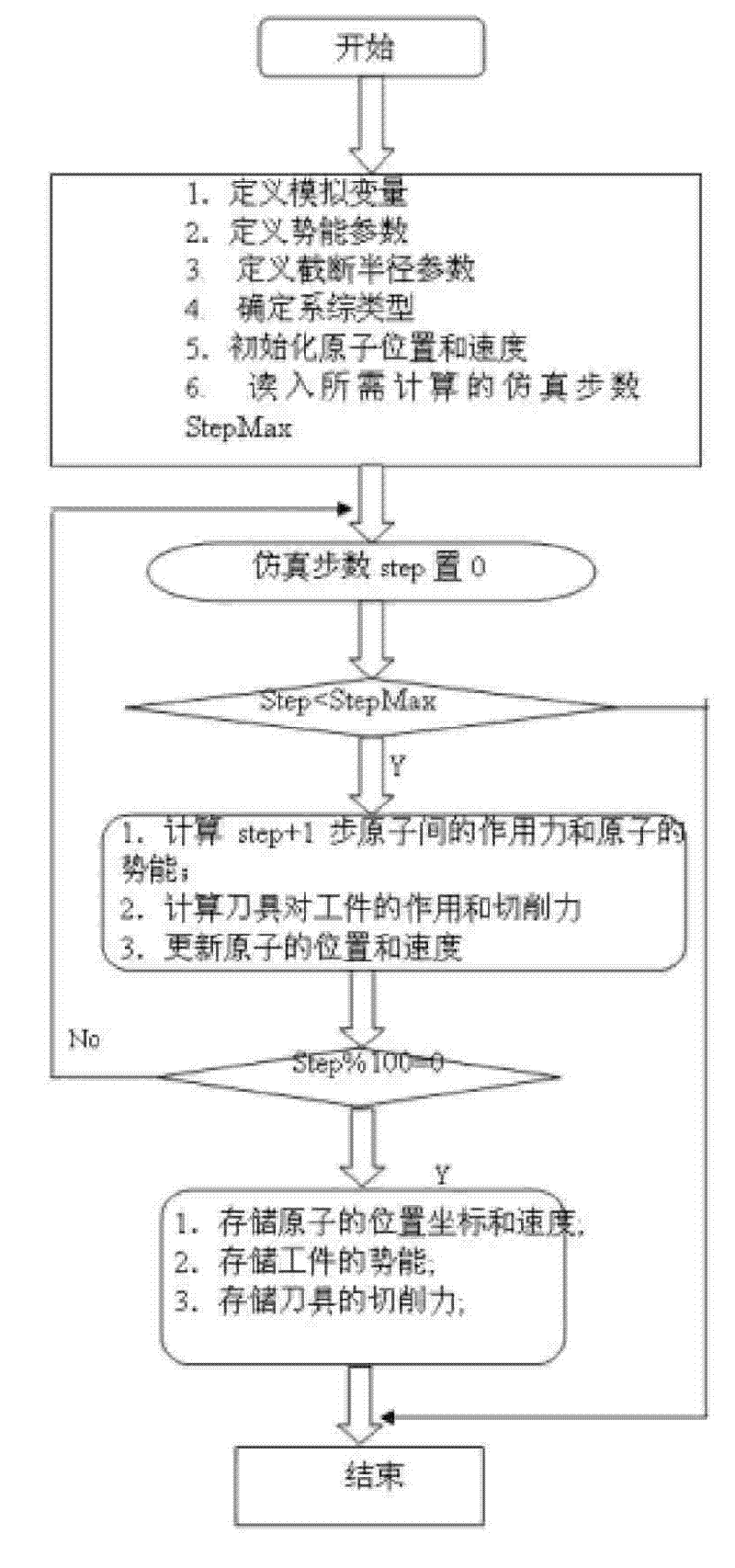

[0025] The present invention will be described in further detail below according to the embodiments and the accompanying drawings.

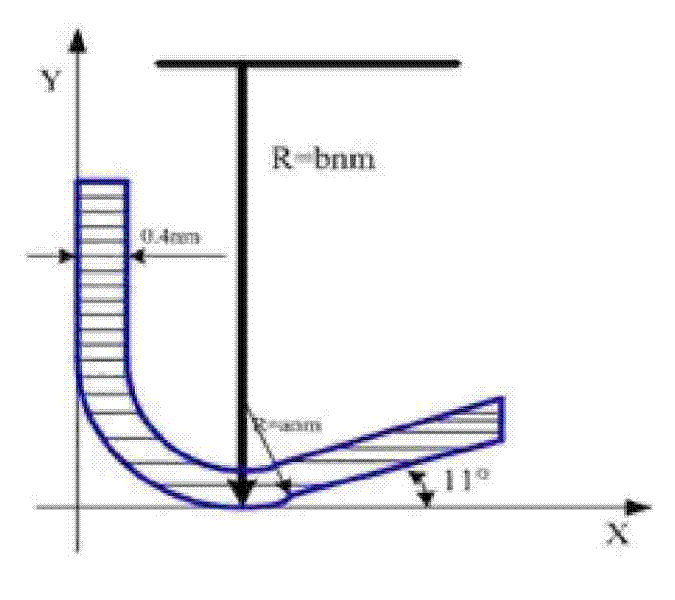

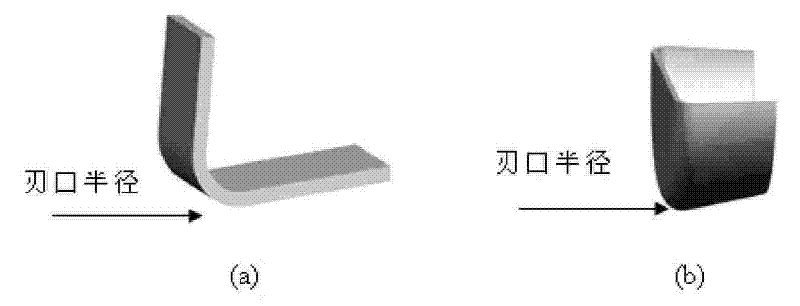

[0026] During molecular dynamics cutting simulation, the workpiece and tool must be arranged according to the rules of atomic composition.

[0027] Using the Fortran language, it is relatively easy to construct solid models of large blocks of diamond and single crystal silicon. In this model, each atom is composed of its three-dimensional point information. In layman's terms, it is to use three numbers accurate to three digits after the decimal point, and the unit is Angstrom, to represent the position of the atom in three dimensions, that is, its space coordinates, and thus determine the position of the atom in space. A typical cutting model can be constructed by further dividing the types of atoms and the shape of entities.

[0028] In order to facilitate the reading of data and the integrity of data information in the next step, most of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com