Test method for molding surface deflection of car sun-roof visor

A detection method and technology for automobile sunroof, applied in the field of detection, can solve the problems of inability to obtain accurate deformation of product profile, unacceptable to consumers, and unsmooth movement of sunroof sunshade, so as to speed up product development cycle and save product development costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0013] The detection method of the profile of the automobile sunroof sunshade comprises:

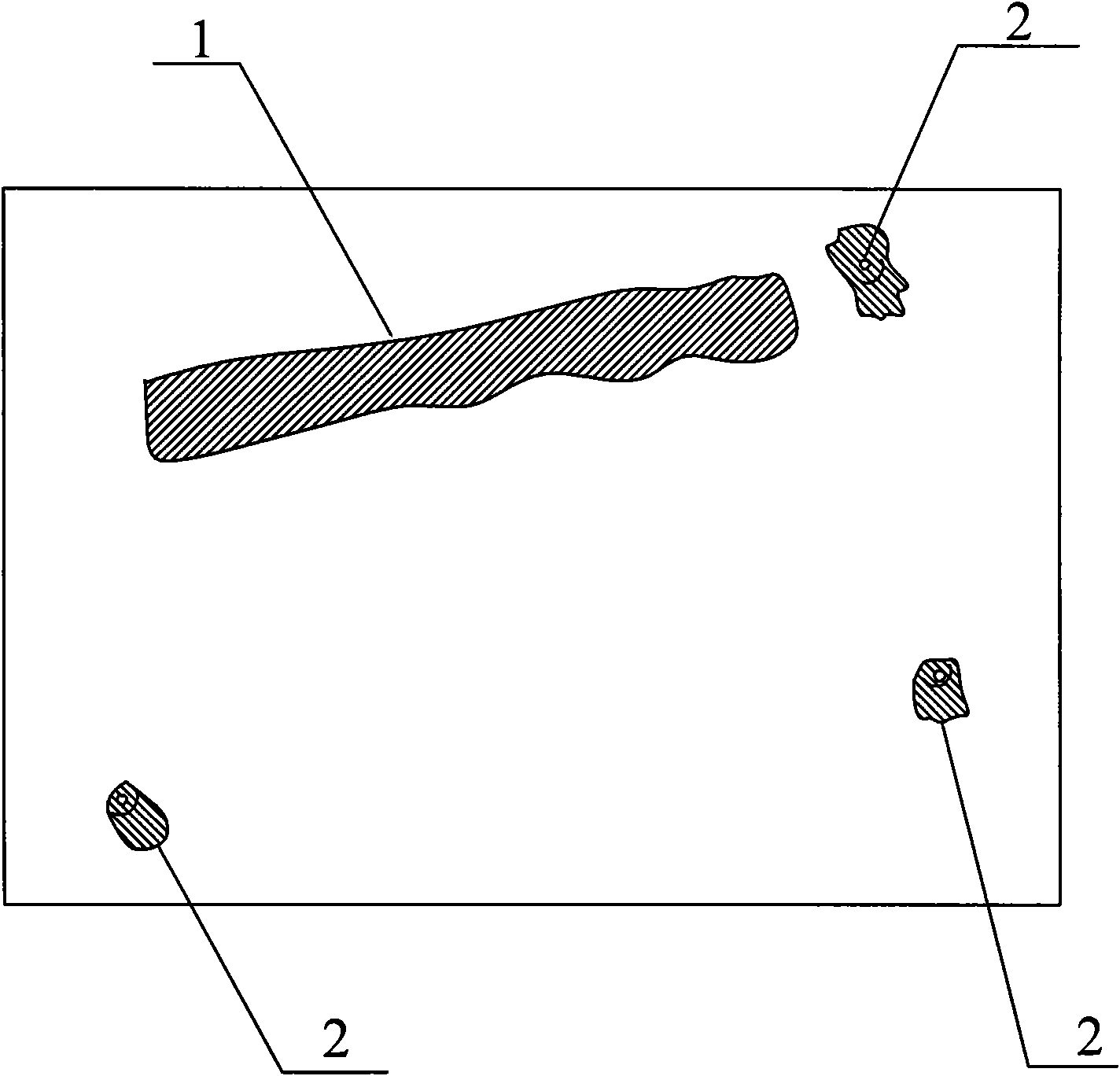

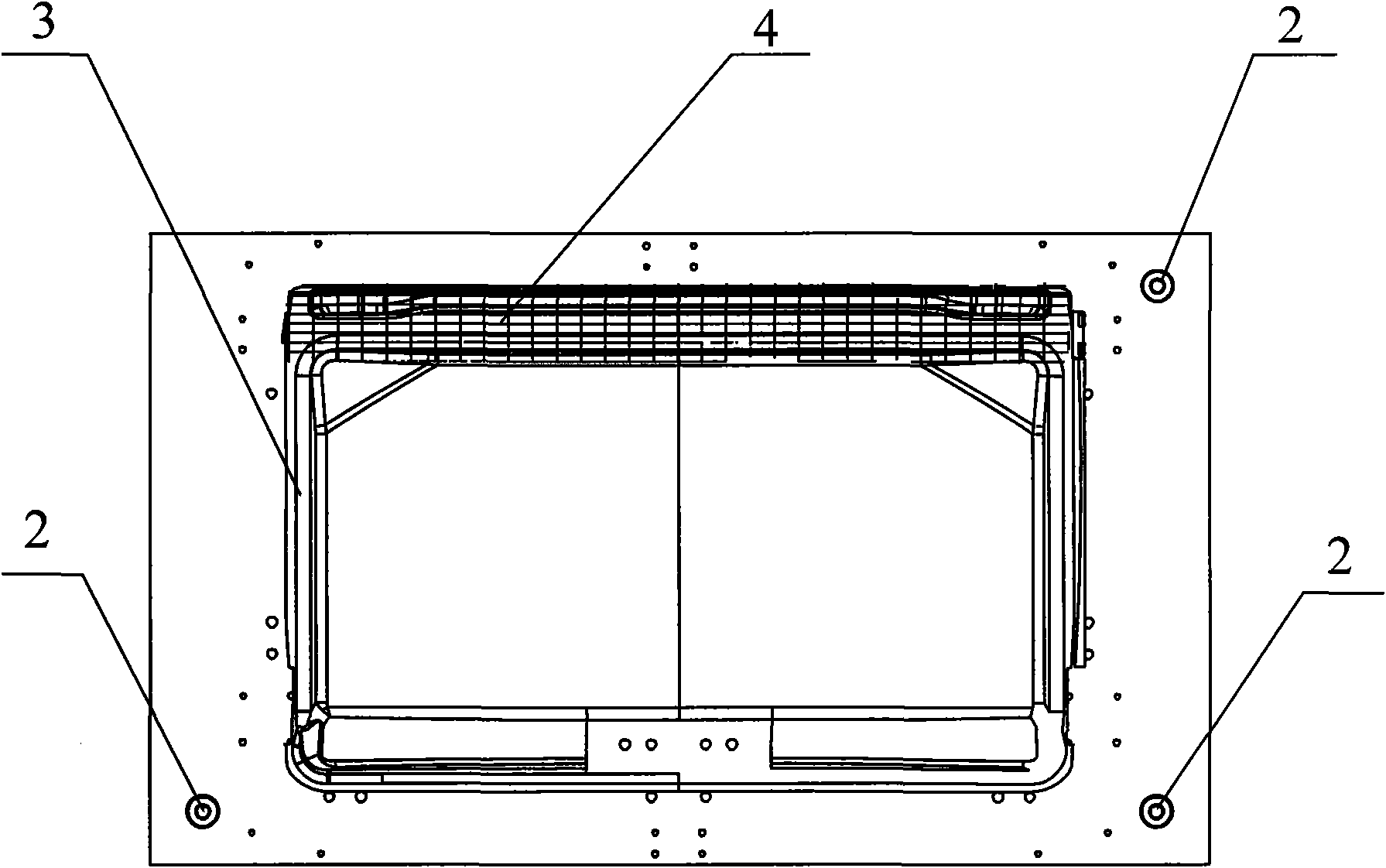

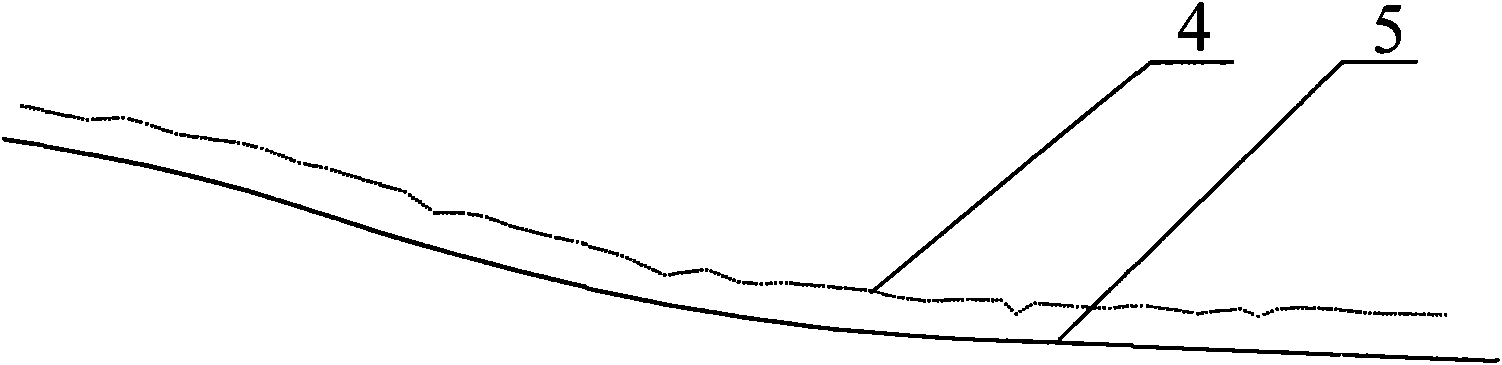

[0014] a. Point cloud data collection: Fix the sunroof sun visor 1 on the inspection tool for detecting the size profile of the sun roof sun visor 1, and use the Scanworks laser scanner to scan the curved surface of the sun roof sun visor 1. When Scanworks scans, there are 25%, 50 %, 100% three kinds of point density, set the corresponding point density; obtain the point cloud data of the curved surface of the sunroof sunshade 1; at the same time, use the Scanworks laser scanner to scan the three detection reference holes 2 on the inspection tool , to obtain the point cloud data of the three detection reference holes 2 of the gage for coordinate alignment;

[0015] b. Coordinate alignment: Import the curved surface of the sunroof sun visor 1 obtained in step (a) and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com