Touch sensing device for touch panel and touch sensing method thereof

A touch sensing, touch panel technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problem of slow touch response time, high channel number, touch signal processing circuit, pixel Light transmittance decreased and other problems, to achieve the effect of fast touch response time, high sensing resolution, and reduced aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

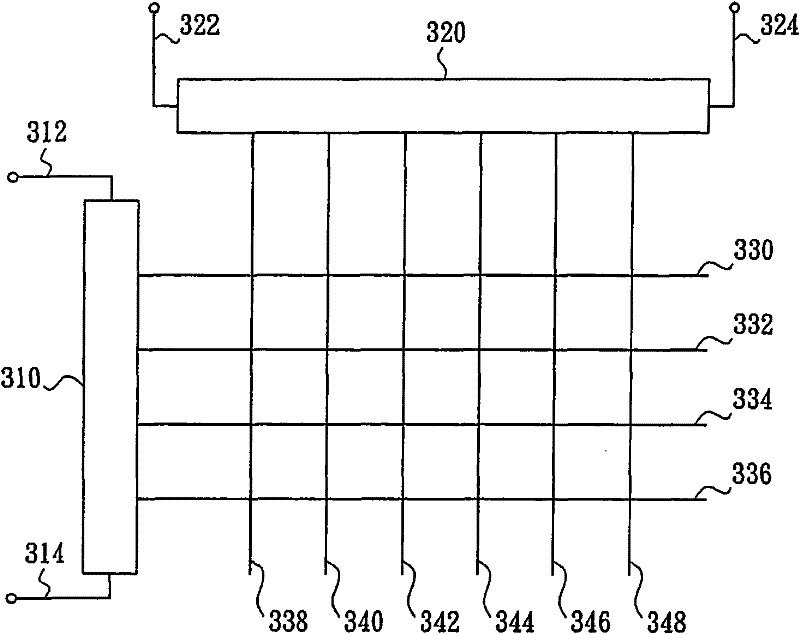

[0061] Please refer to image 3 , which shows a touch sensing device for a touch panel according to an embodiment of the present invention, which is suitable for sensing two-dimensional coordinates of a touch position. As shown in the figure, the touch sensing device mainly includes a conductor 310 , a conductor 320 and wires 330 - 348 . In addition, the touch sensing device also includes touch signal readout lines 312 , 314 , 322 and 324 . The wires 330 - 336 are arranged in parallel, and one end of the wires 330 - 336 is electrically coupled to the conductor 310 to divide the conductor 310 into a plurality of line segments. The wires 338 - 348 are arranged in parallel, and one end of the wires 338 - 348 is electrically coupled to the conductor 320 to divide the conductor 320 into a plurality of line segments.

[0062] The conductors 310 and 320 are made of special materials, so that the resistance of each line segment in the conductors 310 and 320 is greater than the resis...

no. 2 example

[0079] It can be seen from the teaching of the first embodiment that if only image 3 The conductor 310 and the wires 330 - 336 of the touch sensing device shown, or only the conductor 320 and the wires 338 - 348 can be used to sense the touch position. If only the one-dimensional coordinate sensing of the touch position is implemented, it is only necessary to measure two resistance values from the two ends of the conductor, and calculate the one-dimensional coordinate of the touch position accordingly; however, if the touch position is to be implemented For the sensing of the two-dimensional coordinates of the touch position, it is necessary to cooperate with the above formulas (1)-(2) or formulas (3)-(4) to further calculate the coordinates of another dimension.

no. 3 example

[0081] This embodiment is one of the implementation states of the first embodiment. Please refer to Figure 8 , which shows a touch sensing device for a touch panel according to another embodiment of the present invention. exist Figure 8 Among them, marks 810 and 820 all represent conductors, marks 812, 814, 822 and 824 all represent touch signal reading lines, and marks 830-856 all represent wires. In this embodiment, the line width of the wires 830-856 is increased to reduce the resistance of the wires 830-856.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com