Wind-driven electricity generation device with savonius rotor

一种设备、转子的技术,应用在发电机和分段式转子领域,达到装配简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

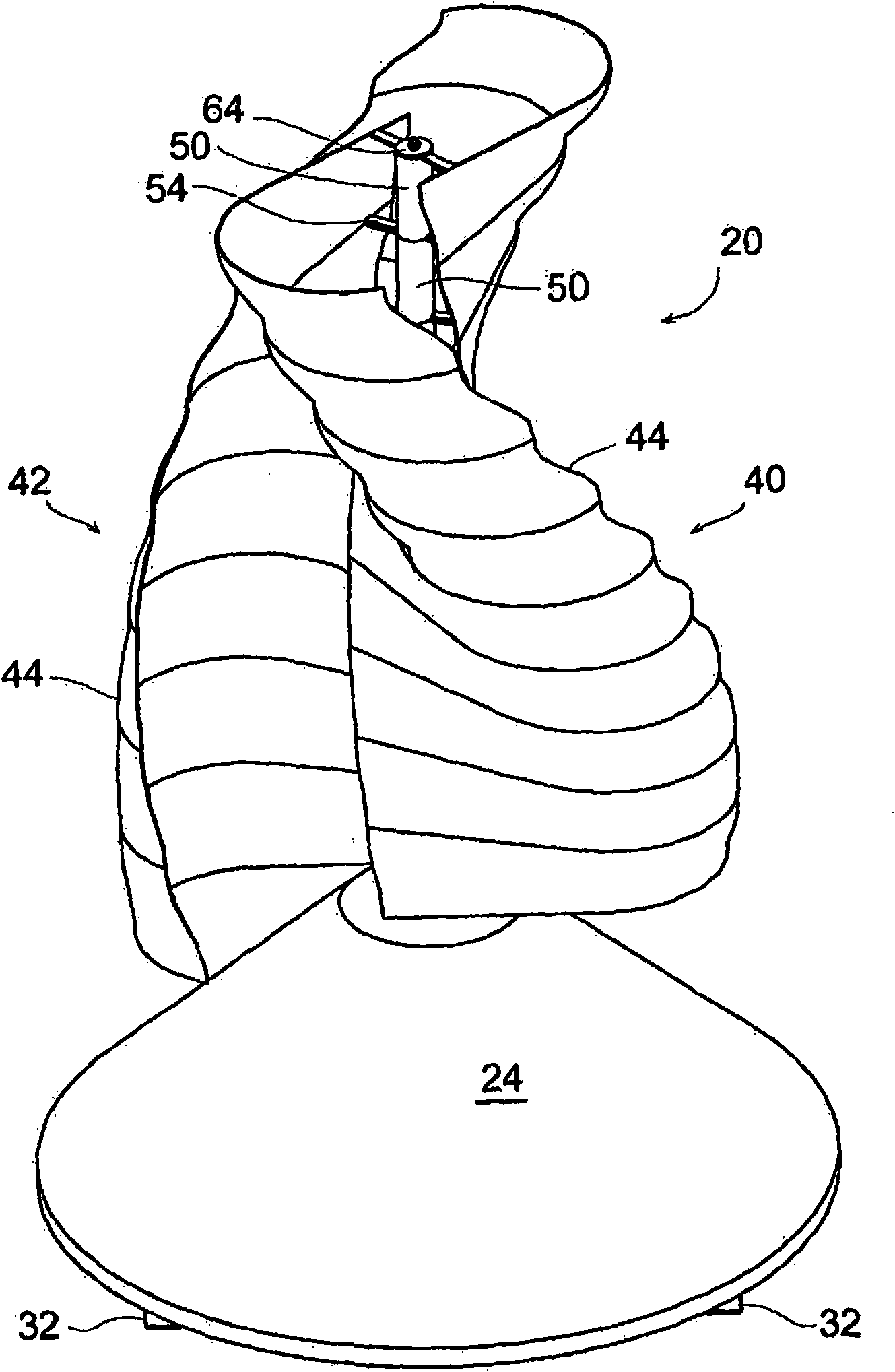

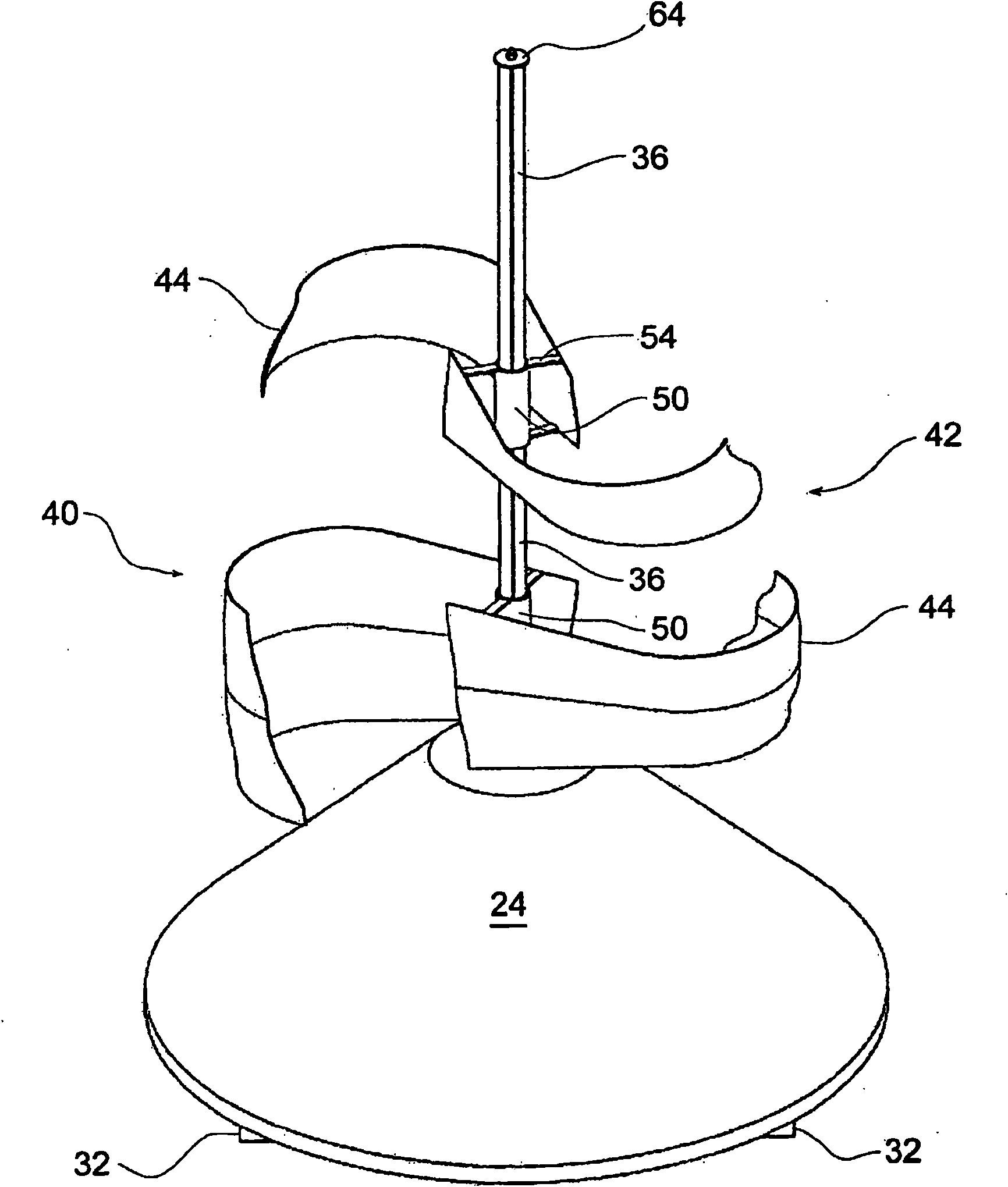

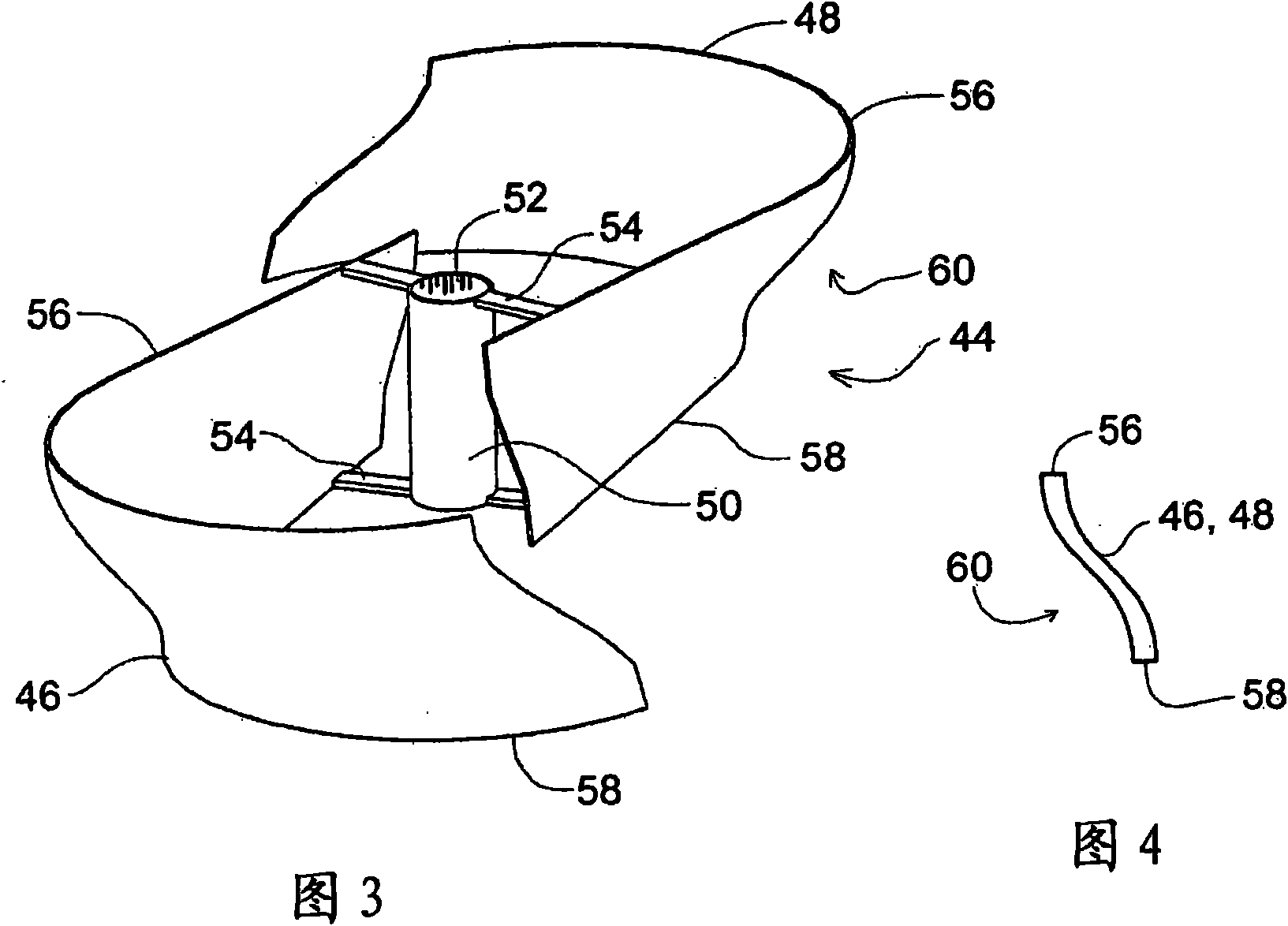

[0028] By referring to the drawings especially figure 1 , figure 2 and Figure 8 , will best understand the invention. In the embodiment shown, the device 20 has a base 22 which can be covered with a conical skirt 24 for appearance. Included in the structure of base 22 are bearings 26 and 28 . A strut 30 arranged radially around the base 22 is attached at the top end to the base and extends diagonally downward. Although for clarity in Figure 8Only two of the struts 30 are shown in , but clearly at least three such struts, preferably four to eight, will be required to fully support the apparatus. Typically, the poles will be equally spaced around the base 22 of the device, but unequal spacing may be used if the device is to be mounted on particularly uneven ground. The strut 30 will be attached at its lower end to a ground engaging structure 32 which may take the form of a circular or polygonal flat plate, or may be a radially projecting rod to which the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com