Minitype automatic sample storing cabinet for storing steel sample

A sample storage cabinet, steel technology, applied in the field of three-dimensional warehouse, to achieve the effect of increasing the bearing weight, avoiding sample mixing, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

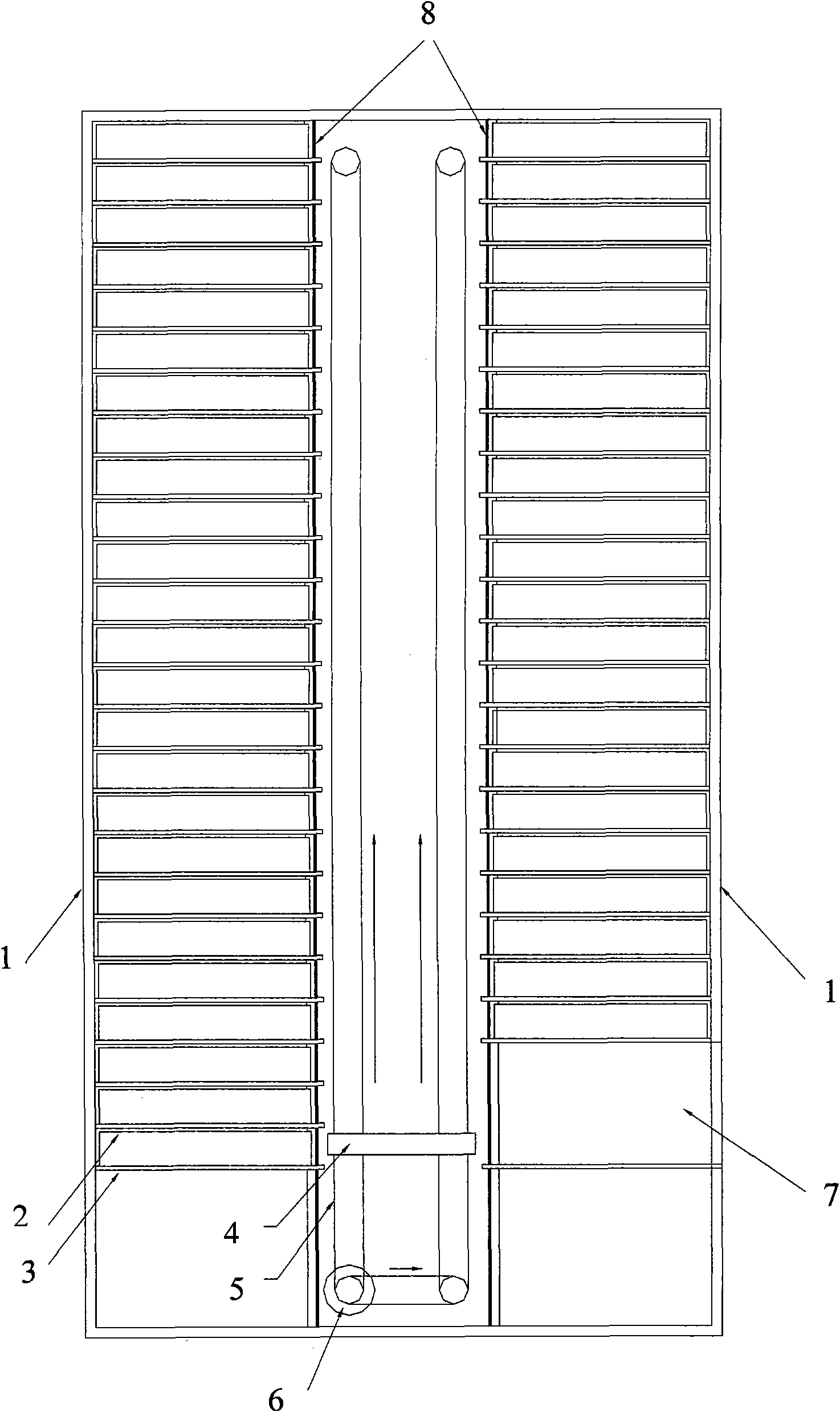

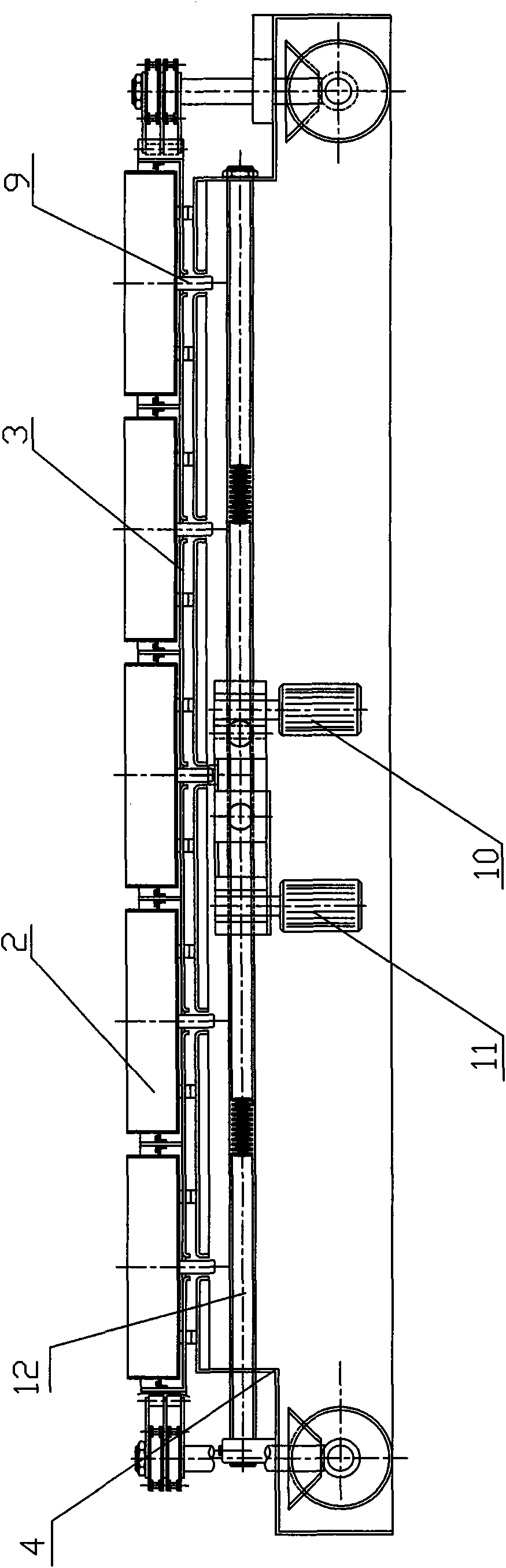

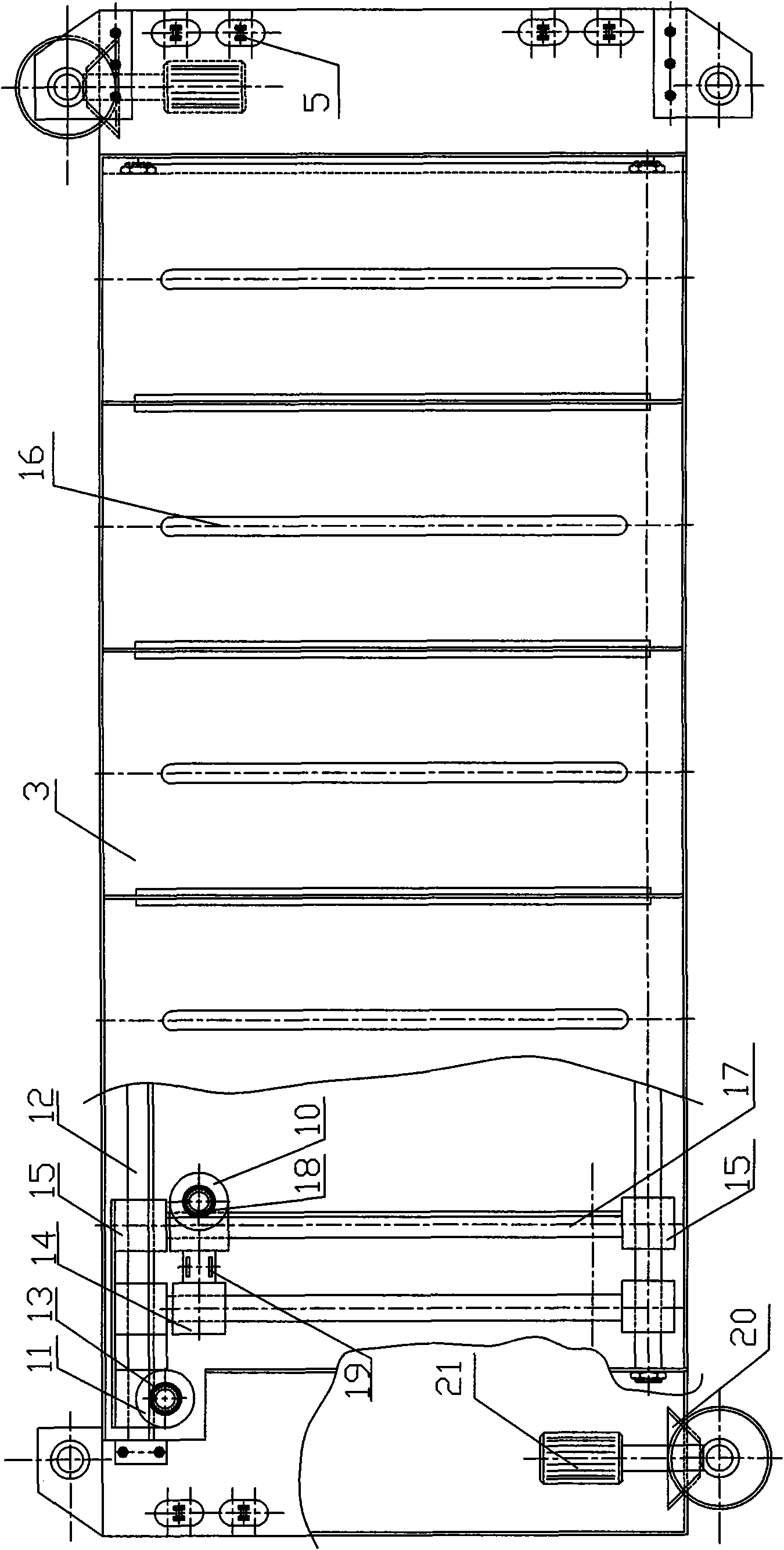

[0023] In order to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments, see Figure 1 to Figure 7 :

[0024] The small-sized automatic sample storage cabinet for iron and steel samples implemented by the present invention, the automatic sample storage cabinet is provided with an operation port 7 for steel samples to go in and out of the warehouse, in order to reduce labor intensity, the operation port 7 is equipped with mechanical facilities for going in and out of the warehouse, For example, in a crawler conveyor, a sample storage rack 1 is arranged in the cabinet for storing trays 3. The sample storage rack 1 includes a base, a frame connected to the base, side plates of a support frame connected to the frame for storing trays 3, and front and rear panels. and top cover. The sample storage rack 1 is a multi-layer structure arranged in two rows f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com