Electric iron improved structure

An improved structure and technology of electric irons, applied in the direction of hand irons, iron pads, washing devices, etc., can solve the problems of unsatisfactory use effect and immature ceramic bottom plate technology, and achieve good ironing effect and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

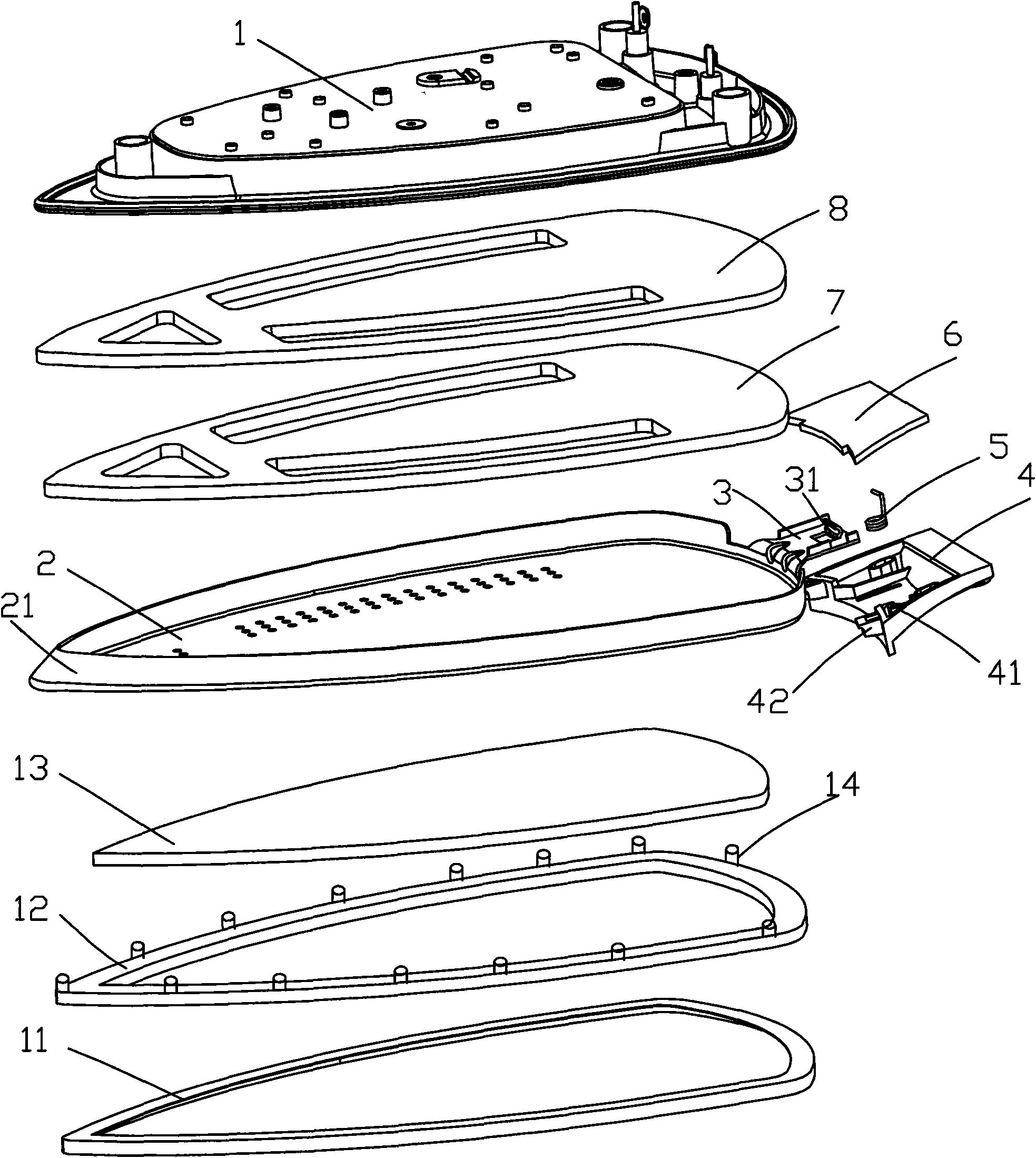

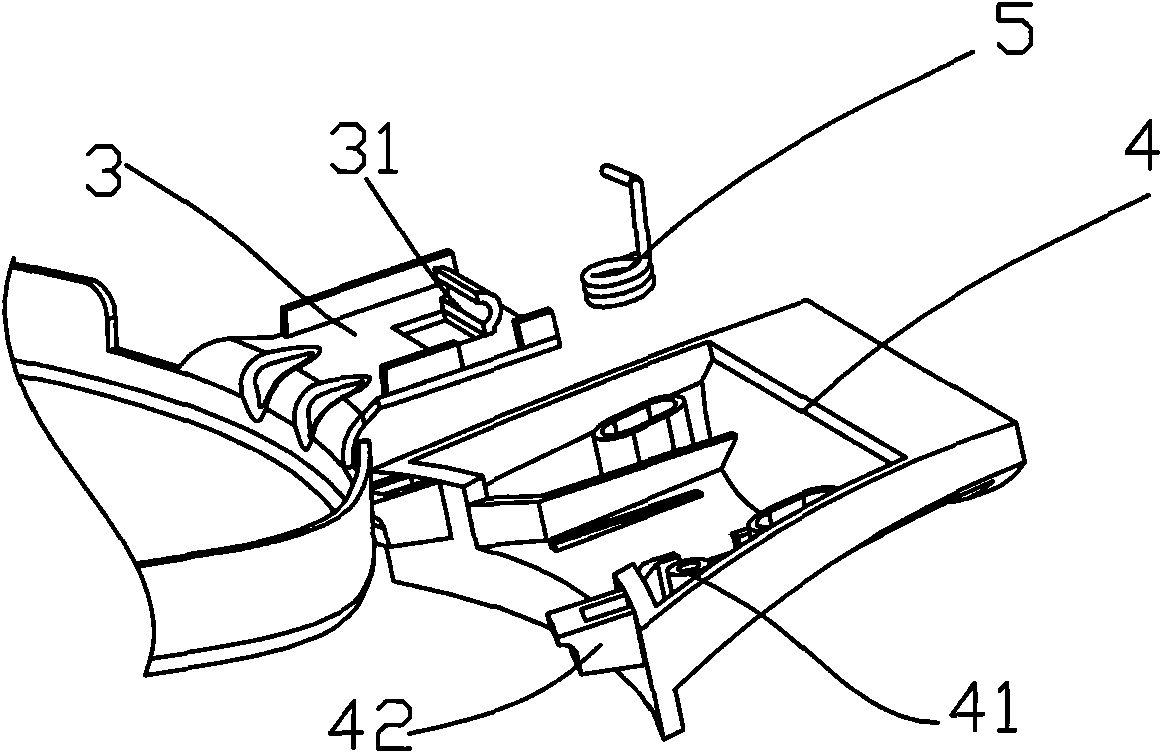

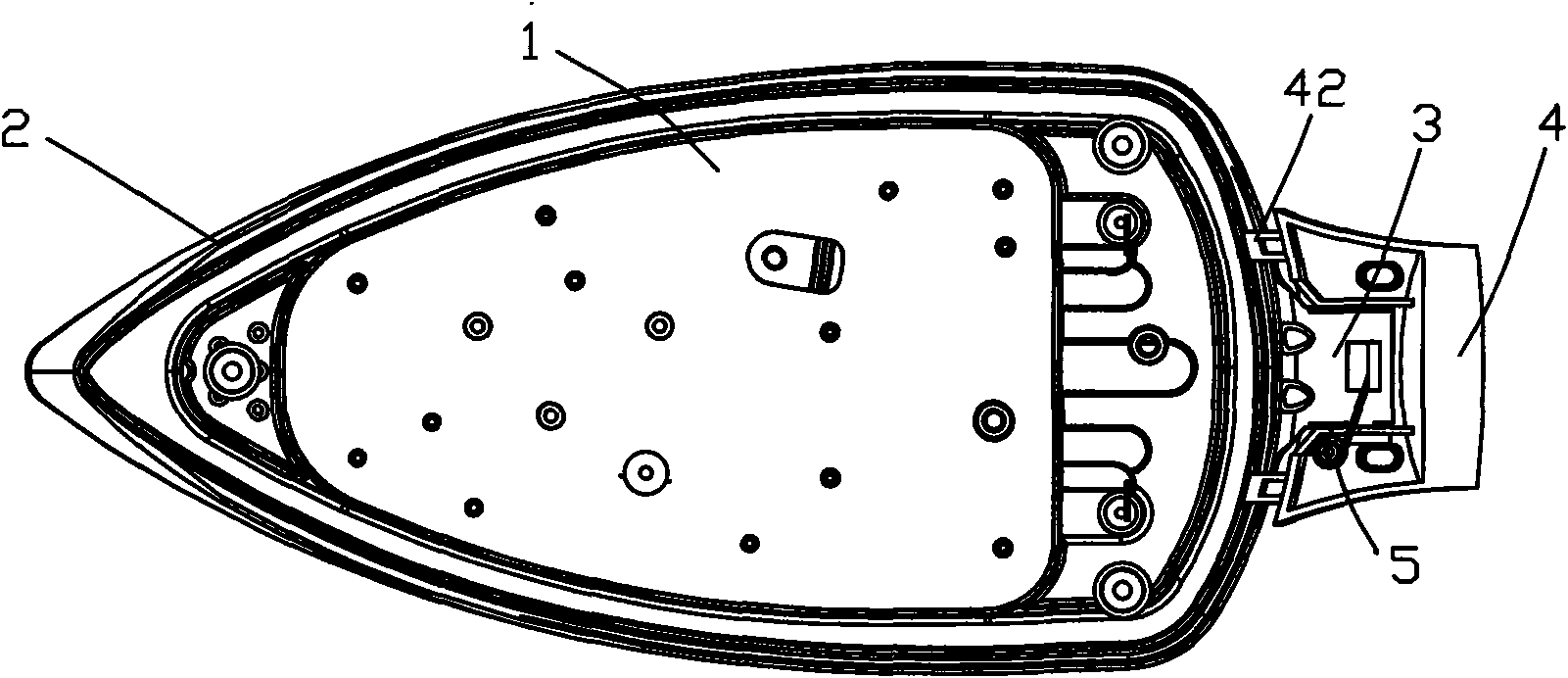

[0021] like Figure 1 to Figure 4 As shown, it is an embodiment of an improved structure of an electric iron according to the present invention, including an aluminum alloy bottom plate 1, and a ceramic plate 2 is provided at the lower part of the aluminum alloy bottom plate for easy disassembly, and the aluminum alloy bottom plate and the ceramic plate are locked by a locking device. Buckle together. The locking device includes lugs 3 at the rear of the ceramic plate, and a locking base 4 flexibly arranged on the lugs. The locking base is provided with a buckle foot 42 pressed on the rear edge of the aluminum alloy base plate. A spring 5 is provided between the lug and the buckle base to generate the pressing force of the buckle foot. The lock base is slid on the lug along the horizontal direction, the lock base is provided with a boss 41, the lug is provided with a slot 31, one end of the spring is sleeved on the boss, and the other end of the spring is snapped on the card....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com