Scroll compressor

A technology for scroll compressors and compression chambers, which is applied to rotary piston machines, rotary piston pumps, mechanical equipment, etc., can solve problems such as supply difficulties and achieve the effect of improved sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

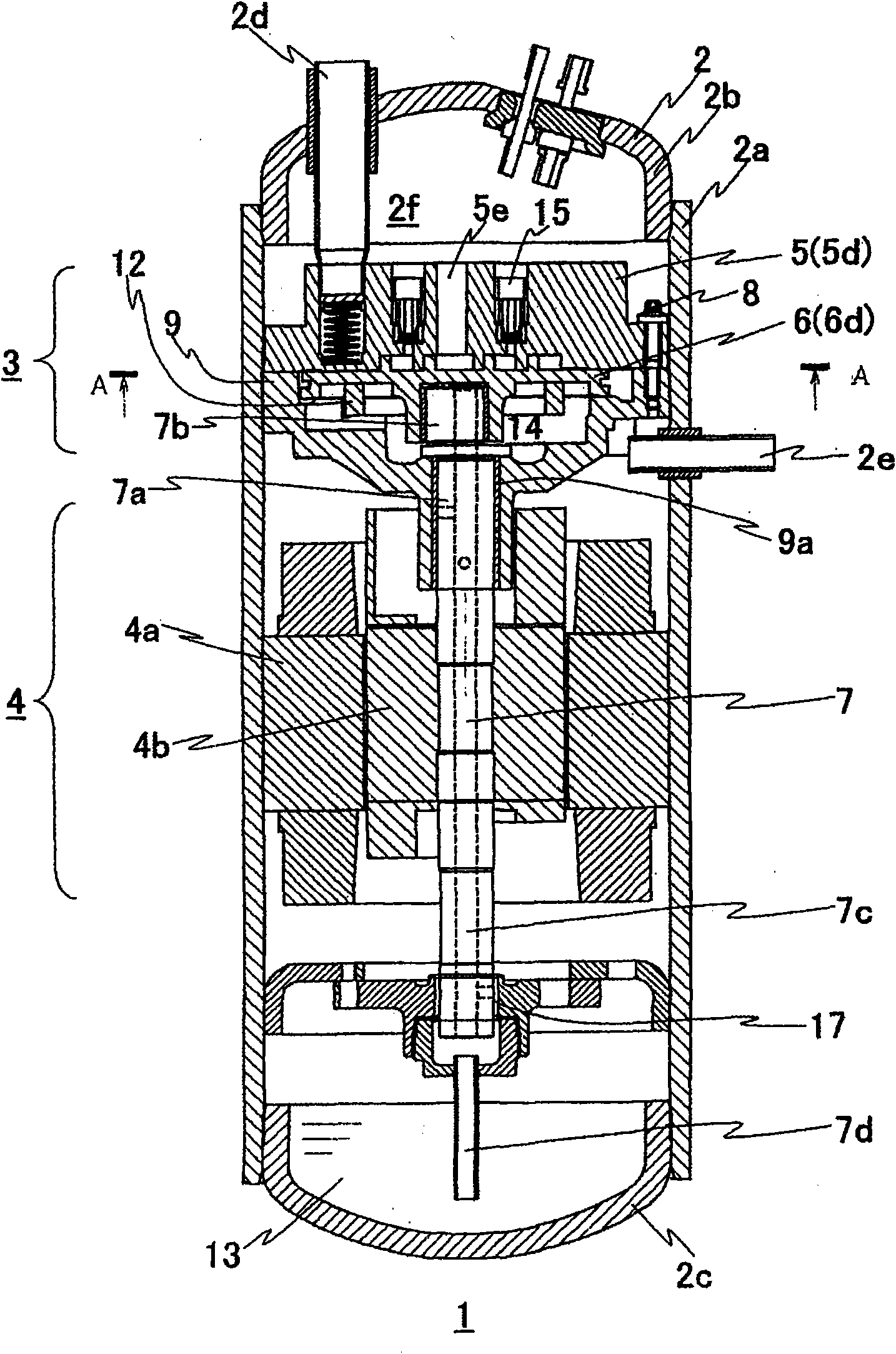

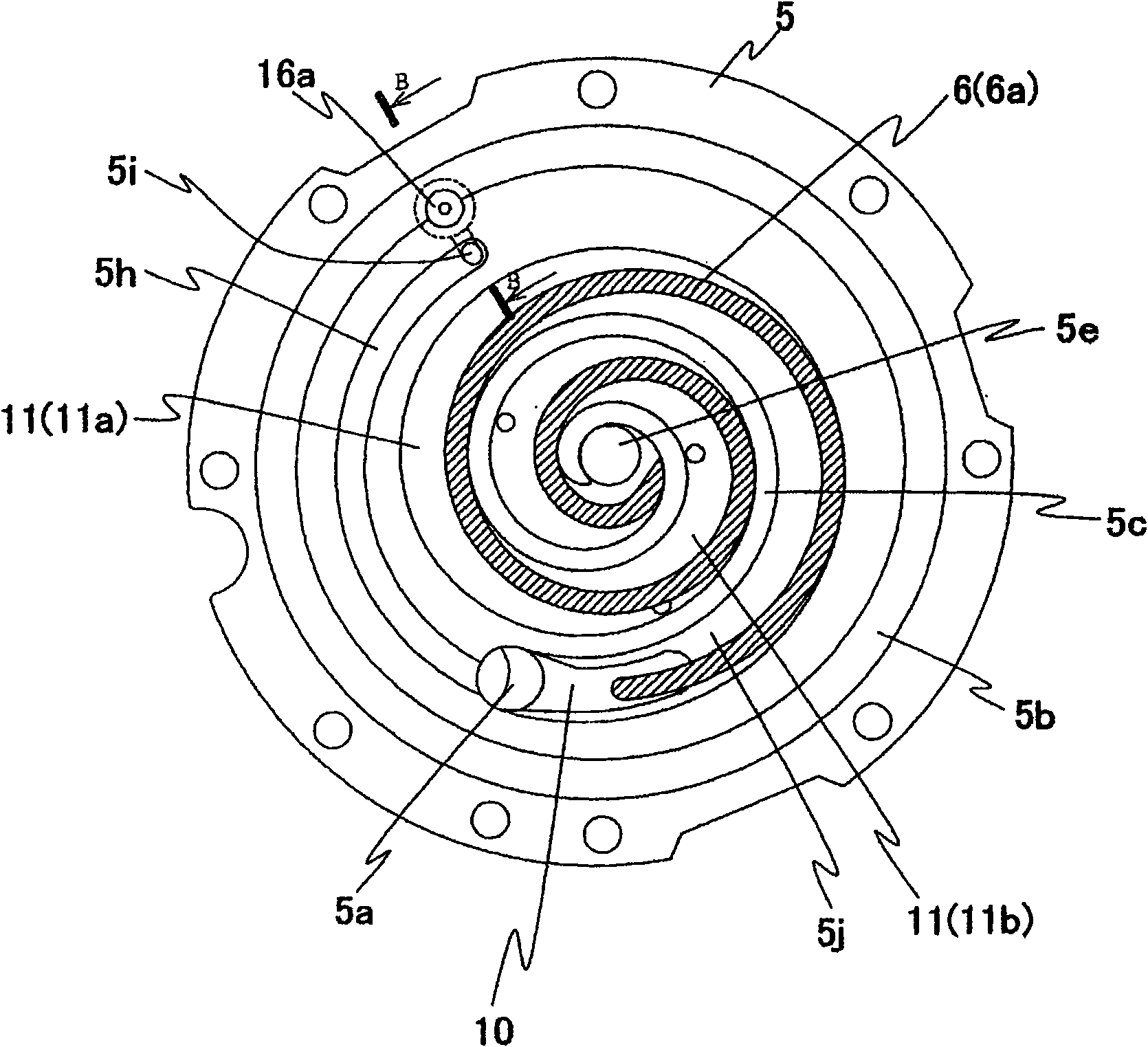

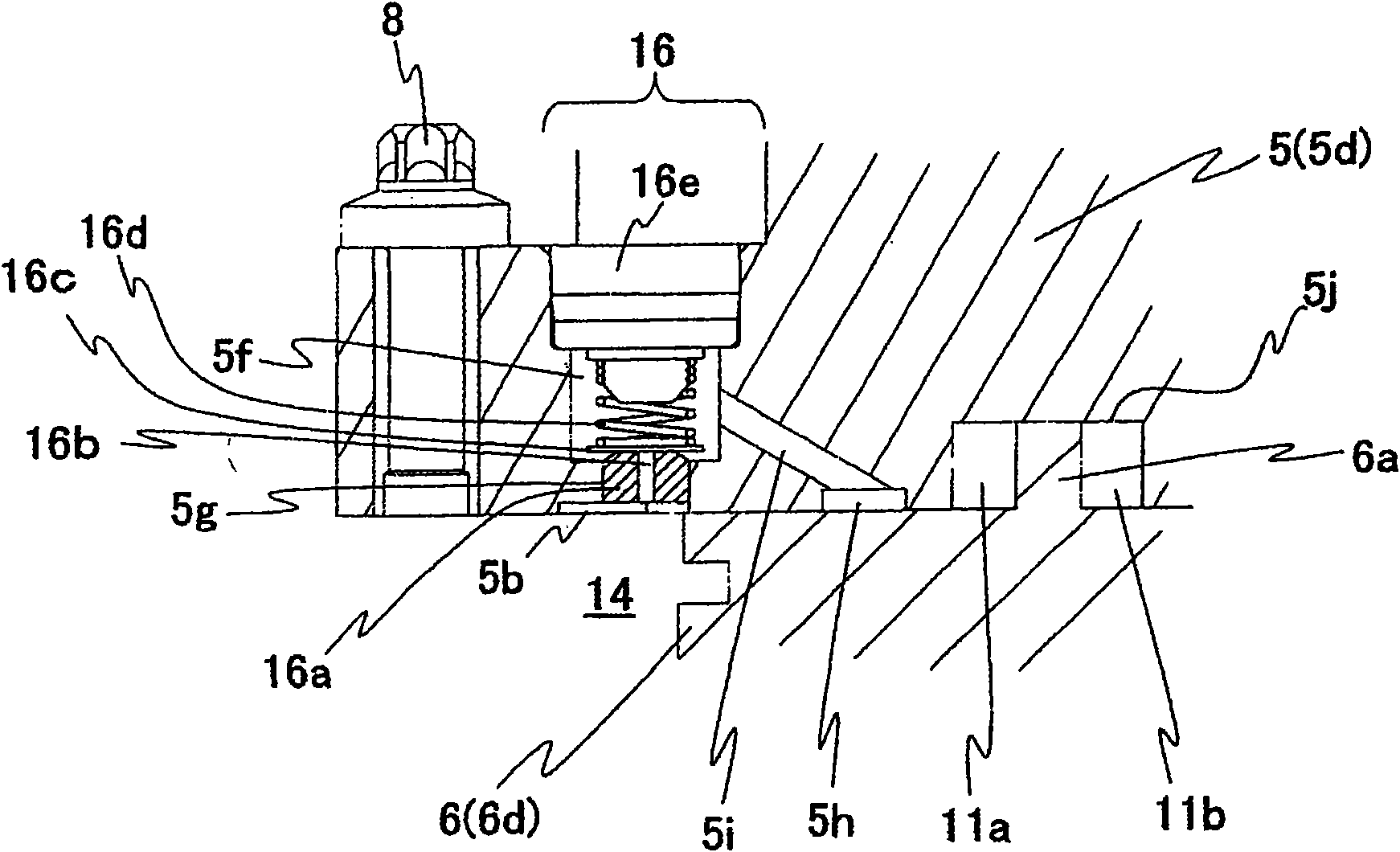

[0021] use Figure 1-Figure 8 A first embodiment of the scroll compressor of the present invention will be described. figure 1 is a longitudinal sectional view of the scroll compressor of the first embodiment, figure 2 is prior art figure 1 The A-A section diagram, image 3 yes figure 2 The B-B section diagram, Figure 4 It is an explanatory diagram when the suction of the rotary outer line chamber is completed, Figure 5 It is an explanatory diagram when the suction of the rotary inner cable chamber is completed, Figure 6 of the first embodiment figure 1 The A-A section diagram, Figure 7 yes Figure 6 The C-C section diagram, Figure 8 It is an explanatory diagram of the oil return method of the back pressure control valve of the first embodiment.

[0022] The scroll compressor 1 is provided with: a compression mechanism part 3, which is composed of an orbiting scroll 6 and a fixed scroll 5 provided with spiral scroll wraps 6a and 5c vertically; and a motor 4 th...

Embodiment 2

[0040] use Figure 9 A second embodiment of the present invention will be described. Figure 9 of the second embodiment Figure 6 The C-C section diagram. Here, since the basic structure is the same as that of Embodiment 1, detailed description is omitted.

[0041] The difference from the first embodiment is that the conduction path 5i connecting the spring receiving hole 5f and the dedendum surface 5j is inclined with respect to the dedendum surface 5j. By inclining the guide path 5i with respect to the dedendum surface 5j, the compressor can be easily assembled. That is, before the sealing member 16e is press-fitted, a drill is inserted through the hole of the sealing member 16e to process the conduction path 5i, and thereafter, the conduction passage 5i does not need to be formed separately when the seal member 16e is press-fitted. Assembly becomes easy without the labor and time of hole plugging.

[0042] use Figure 10 A third embodiment of the present invention wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com