Deburring device

A deburring and spindle technology, which is applied in the direction of machine tools, grinding machines, metal processing equipment, etc., which are suitable for grinding the edge of workpieces, can solve the problems of difficult deburring and deburring, and achieve the effect of effective deburring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

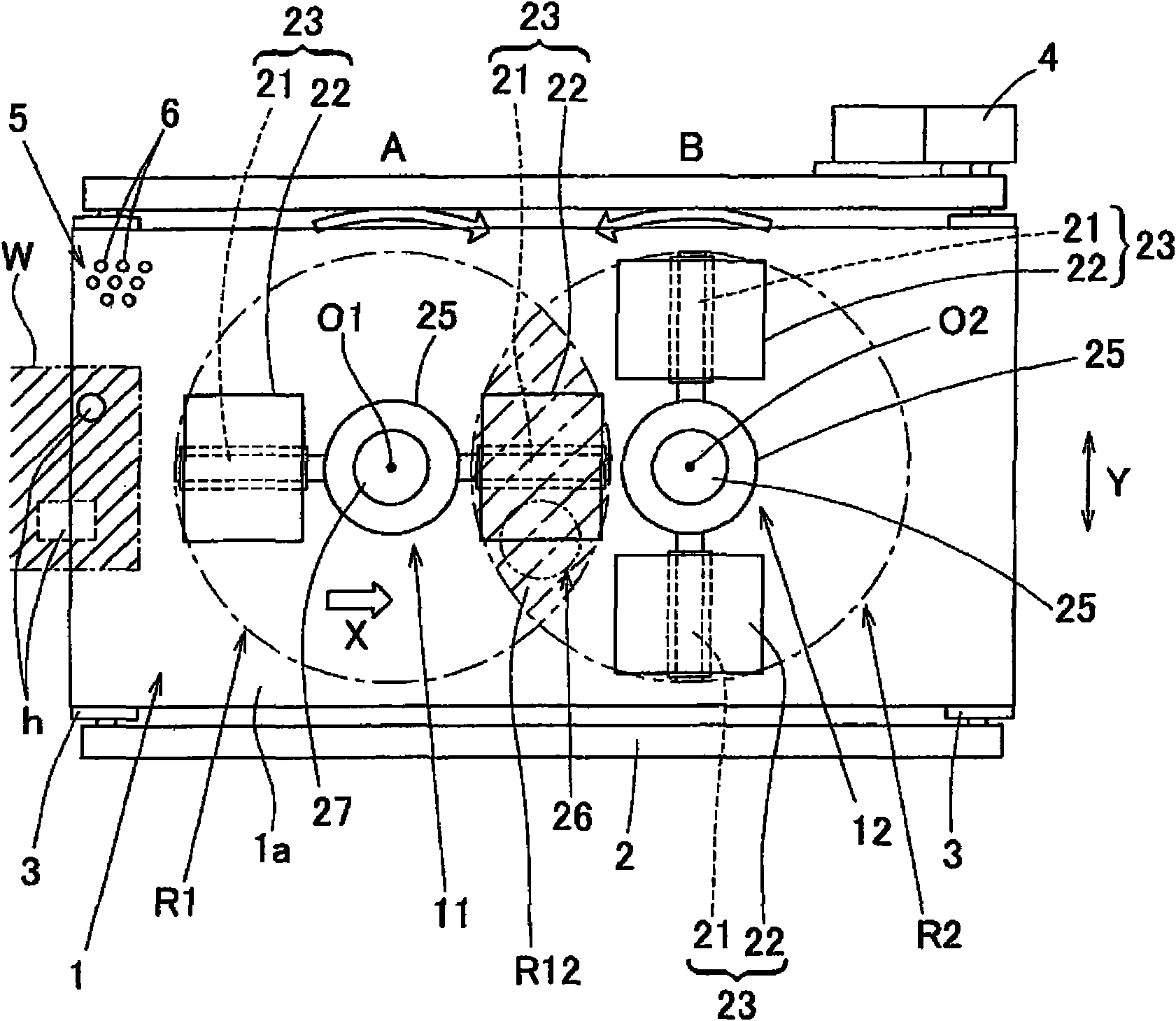

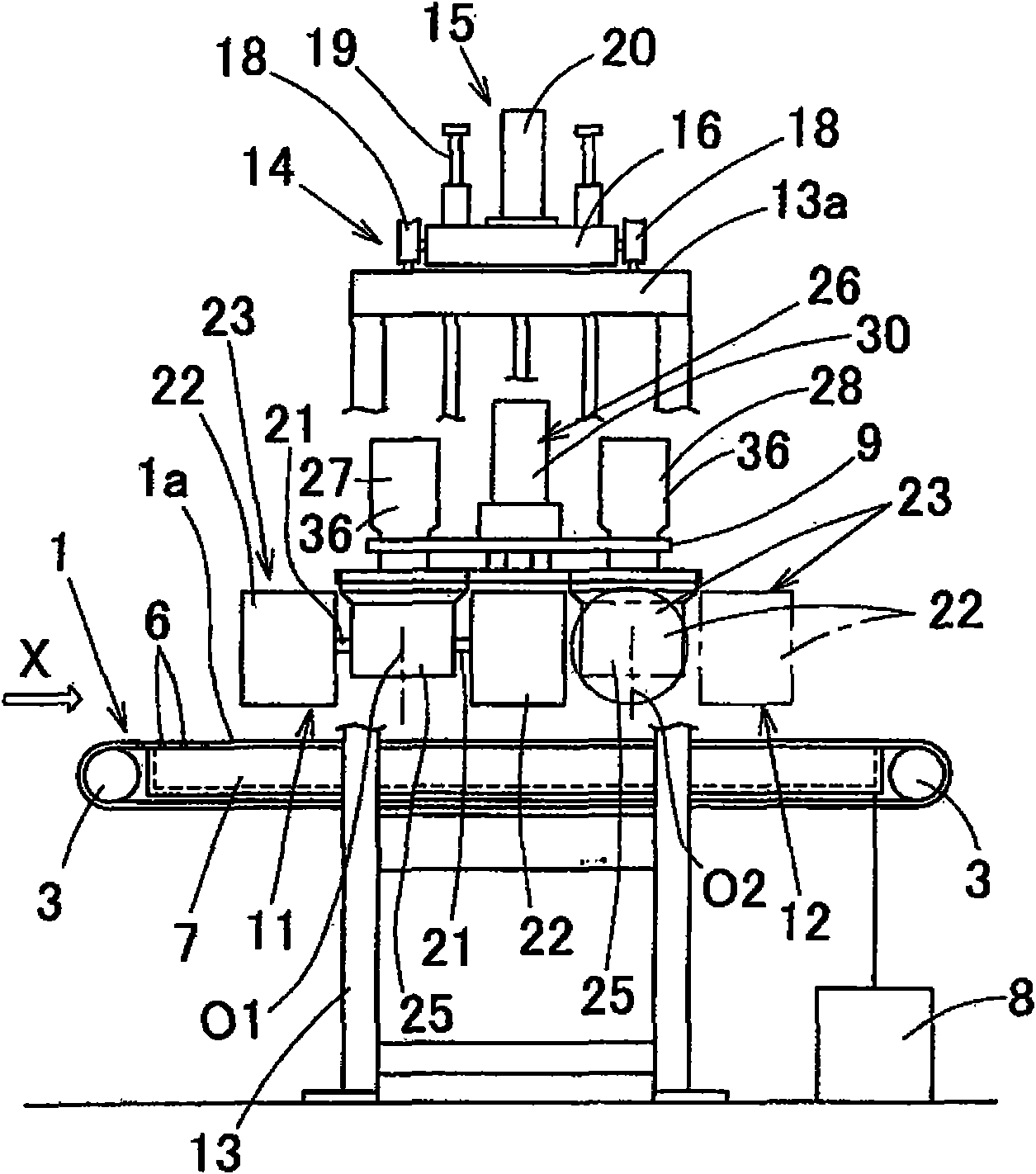

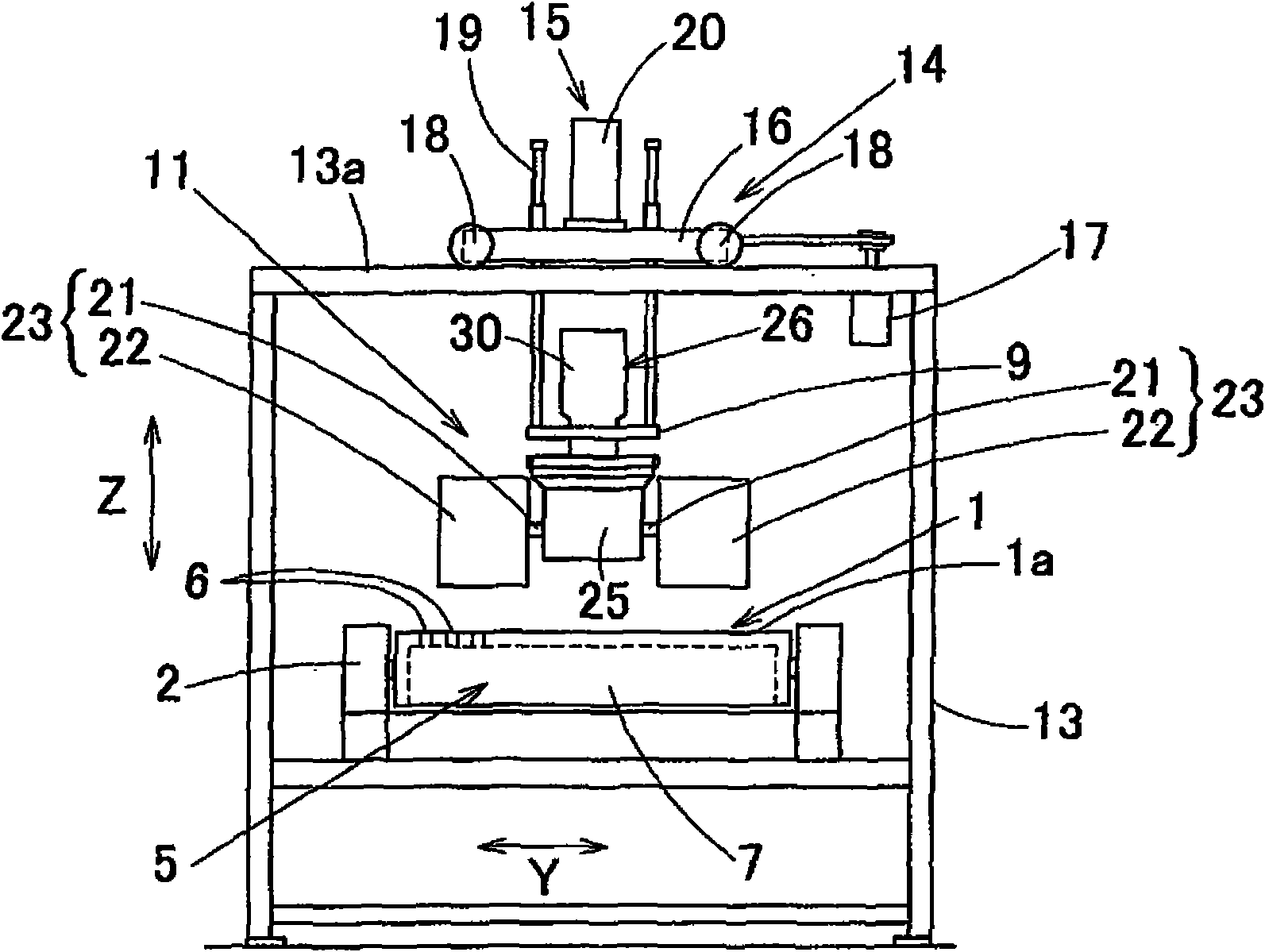

[0036] combine Figure 1 to Figure 9 , to illustrate an embodiment of the present invention. This deflashing device includes a conveyor 1 for conveying the workpiece W, and first and second deflashing heads 11 and 12 positioned above the conveyor 1 and arranged side by side in the conveying direction (arrow X direction). The workpiece W is a flat sheet such as a sheet metal, and is subjected to punching of the hole h, cutting of the outer periphery, or the like by a punch or other sheet metal processing machine. When the workpieces W are large pieces, they are arranged in a single row on the conveyor 1, and when the workpieces W are small pieces, multiple pieces are placed side by side in the width direction.

[0037] The conveyor 1 is a belt conveyor configured by hanging an endless conveyor belt 1 a on rollers 3 at front and rear ends of a conveyor frame 2 . The roller 3 at one end is driven by a drive source 4 such as a motor. The conveyor 1 is provided with a workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com