Double-secondary beam type combined house beam

A technology for secondary beams and house beams, applied in joists, girders, truss beams, etc., can solve the problems of inconvenience, safety, efficiency, cumbersome manufacturing and installation steps, and impact tightness, etc., and achieve a simple and fast assembly method. , the effect of easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

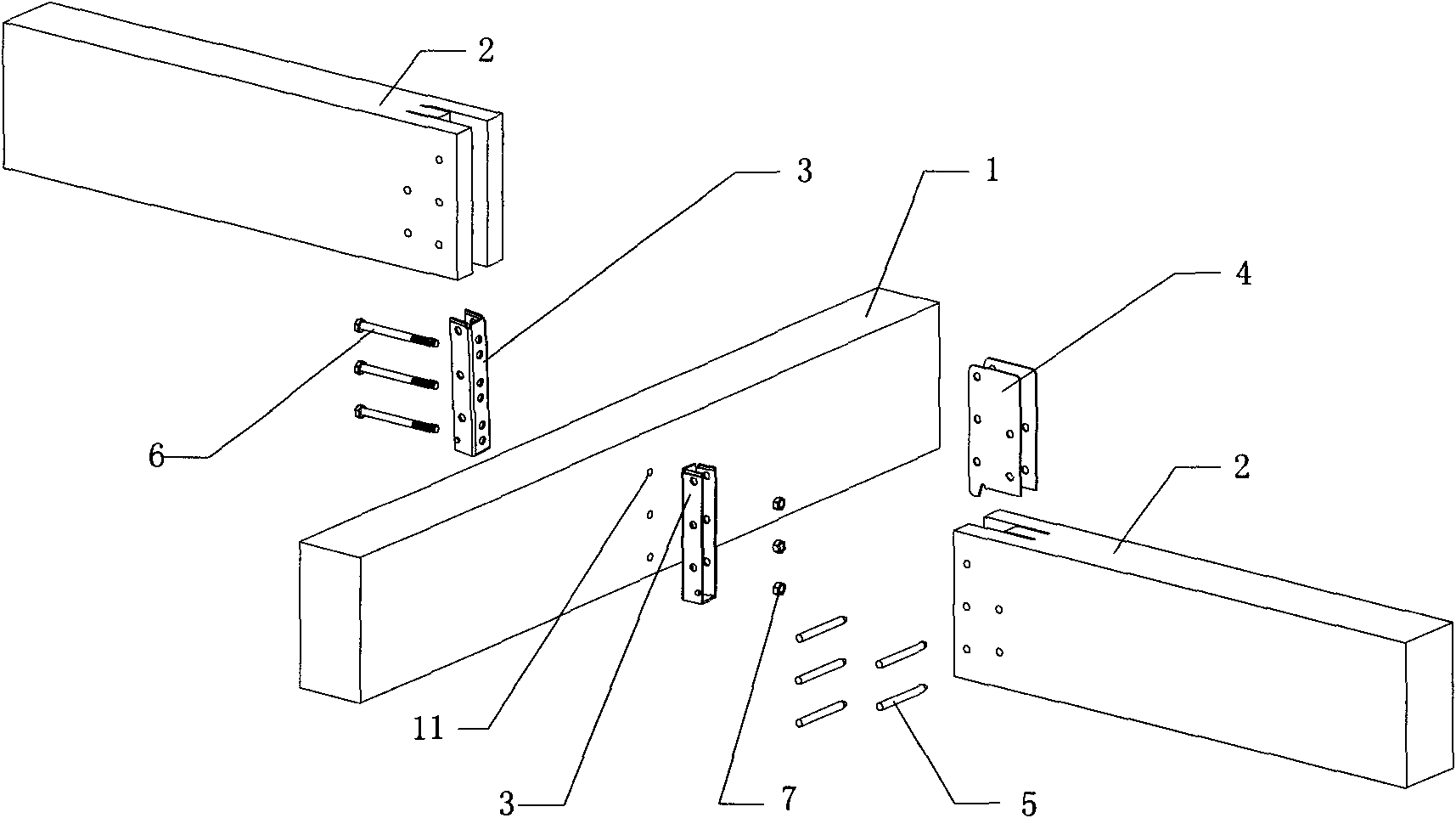

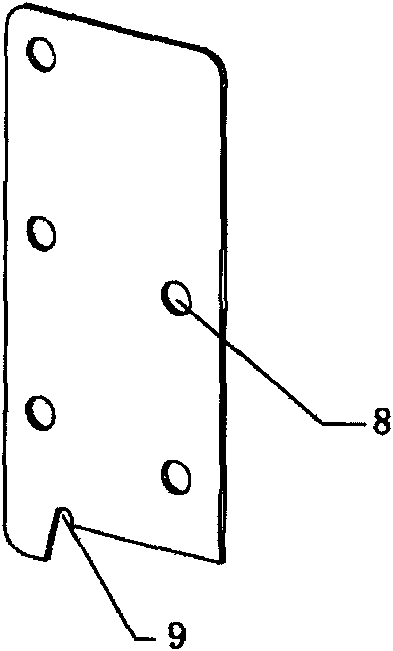

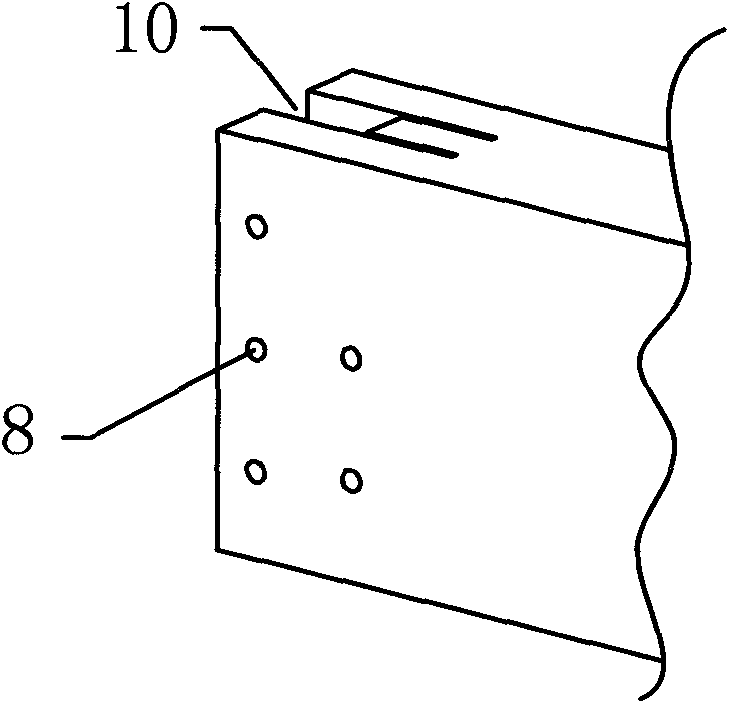

[0024] A double-secondary beam composite house beam, including a main beam 1, and the corresponding secondary beams 2 are installed on both sides of the main beam 1. The "U" type connecting fastener 3 is provided with a hanging plate 4 on the connecting end of the secondary beam 2. When the main beam 1 and the secondary beam 2 are combined, the hanging plate 4 is connected with the "U" type connecting fastener 3.

[0025] Specifically, if figure 2 , image 3 As shown: In order to ensure a stable pre-combination between the secondary beam 2 and the mounting fins, the connecting end of the secondary beam 2 is provided with mounting grooves 10, and the hanging plate 4 is extended with mounting fins, which are embedded in the mounting grooves within 10. At the same time, in order to facilitate the stable combination of the secondary beam 2 and the mounting fins, the connecting end of the secondary beam 2 and the hanging plate 4 are provided with corresponding mounting pin holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com