Electro-thermal detonation fast-response temperature-sensitive rotary spraying fire extinguishing apparatus

A technology of rotating sprinkler and fire extinguishing device, applied in fire rescue and other directions, can solve the problems of delayed bursting of glass temperature sensing elements, delayed sprinkler fire extinguishing, etc., and achieve the effect of high degree of automation, fast response speed, and large spray range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

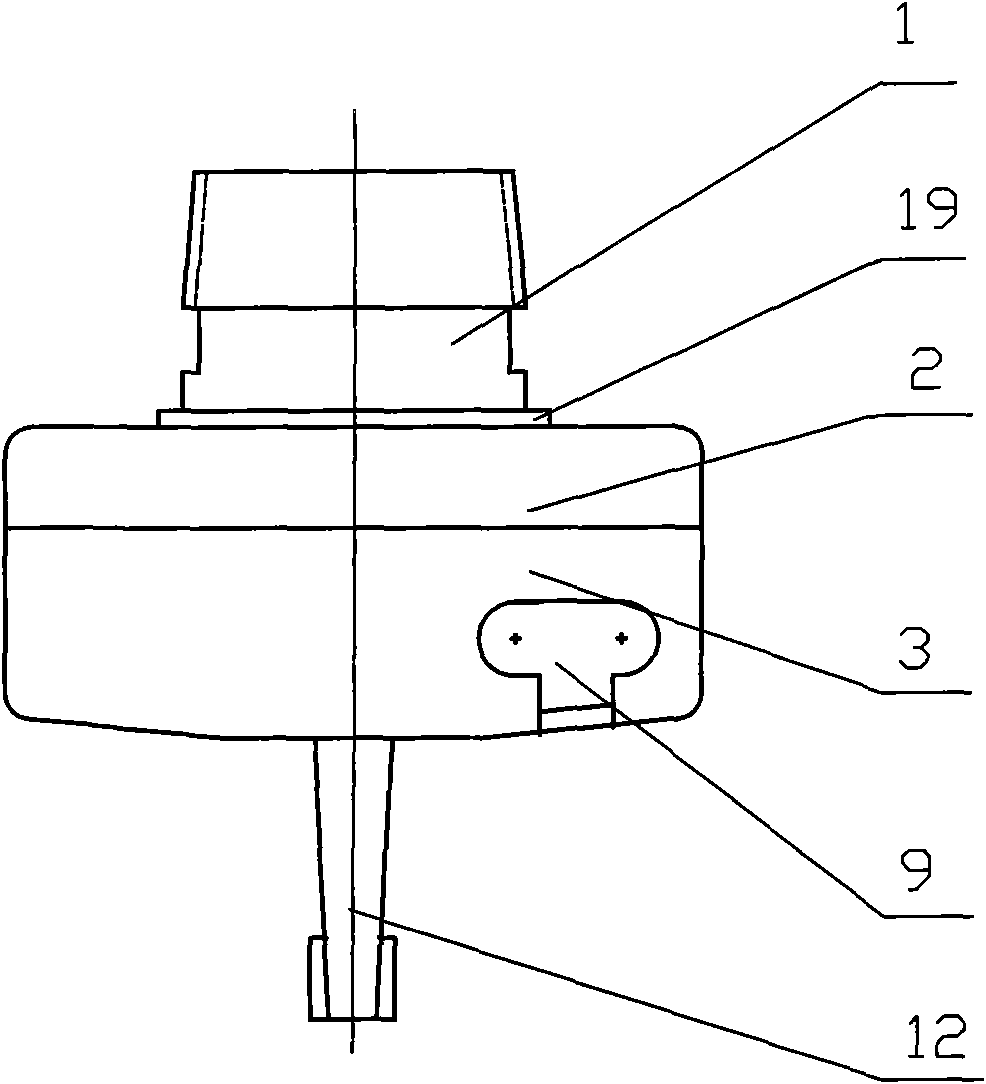

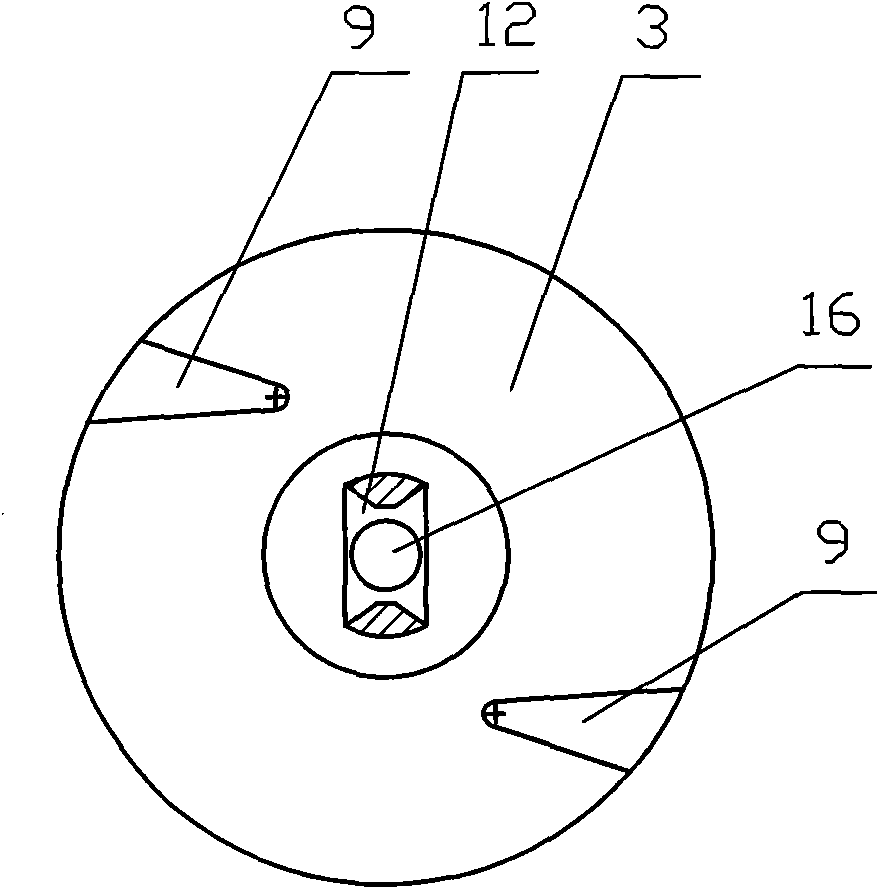

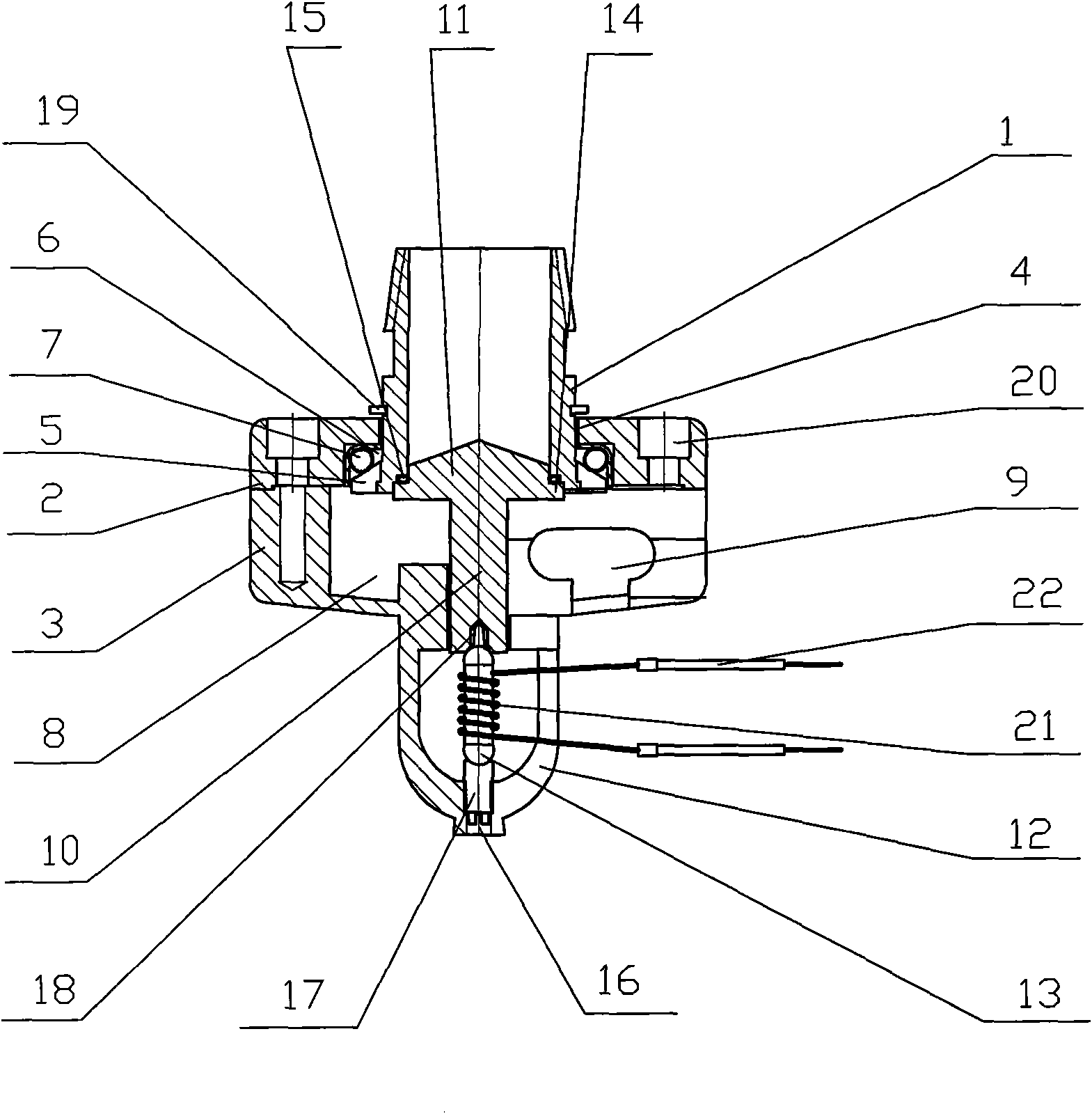

[0020] like Figure 1-4 As shown, the temperature-sensitive rotary sprinkler fire extinguishing device provided by the embodiment of the present invention provides a fast response to electrothermal detonation, including a water inlet pipe 1 and a faucet body. The faucet body is composed of a faucet cover 2 and a faucet 3. The faucet cover 2 The middle part is provided with a through hole 4, the aperture of the through hole 4 is equivalent to the pipe diameter of the water inlet pipe 1, and one end of the water inlet pipe 1 is provided with an outwardly extending pipe shoulder 5, and the water inlet pipe 1 is installed in the through hole 4 of the faucet cover 2 The place is connected with the faucet body, the pipe shoulder 5 of the water inlet pipe 1 and the inside of the faucet cover 2 form an annular gap 6, and a group of balls 7 are placed in the gap 6; It communicates with the water inlet pipe 1, and a group of wedge-shaped water outlets 9 deviated from the center line and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com