Box clamping mechanism

A clamping mechanism and box technology, which is applied in the stacking, transportation and packaging of objects, can solve the problems of production line restrictions and production line efficiency, and achieve the effect of high work efficiency and flexible clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

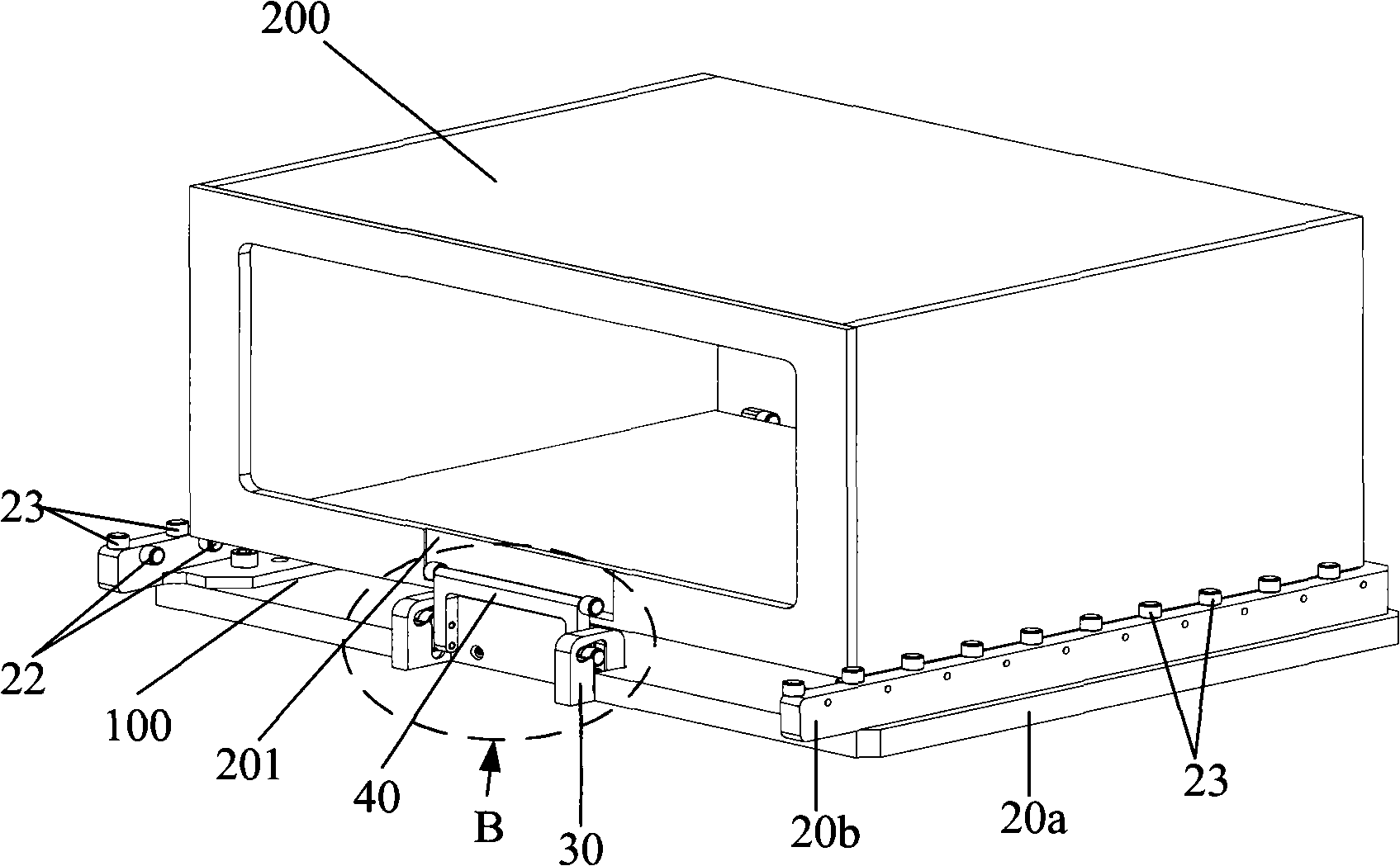

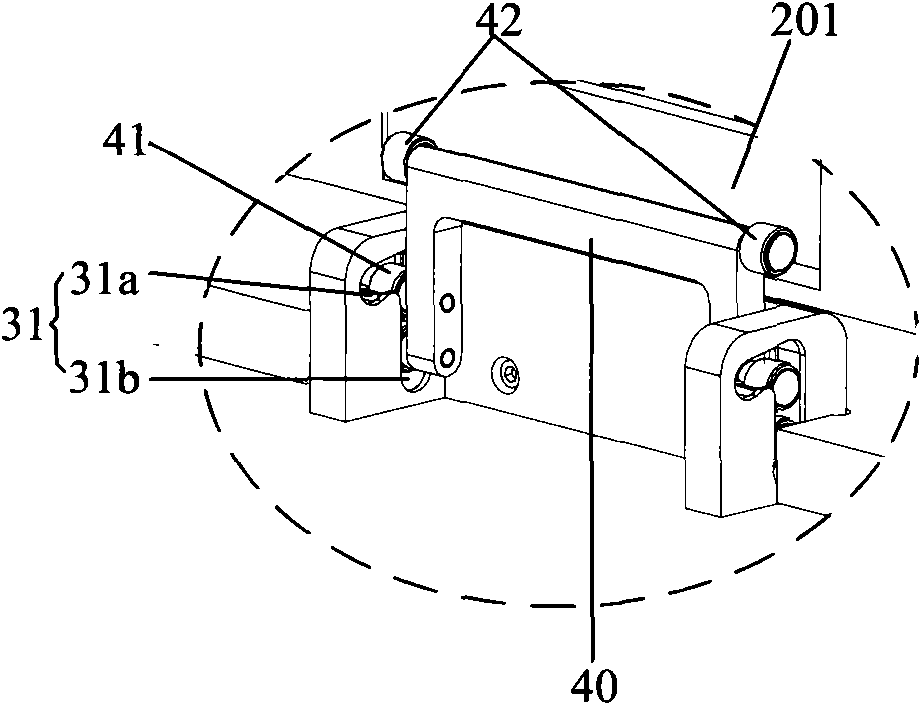

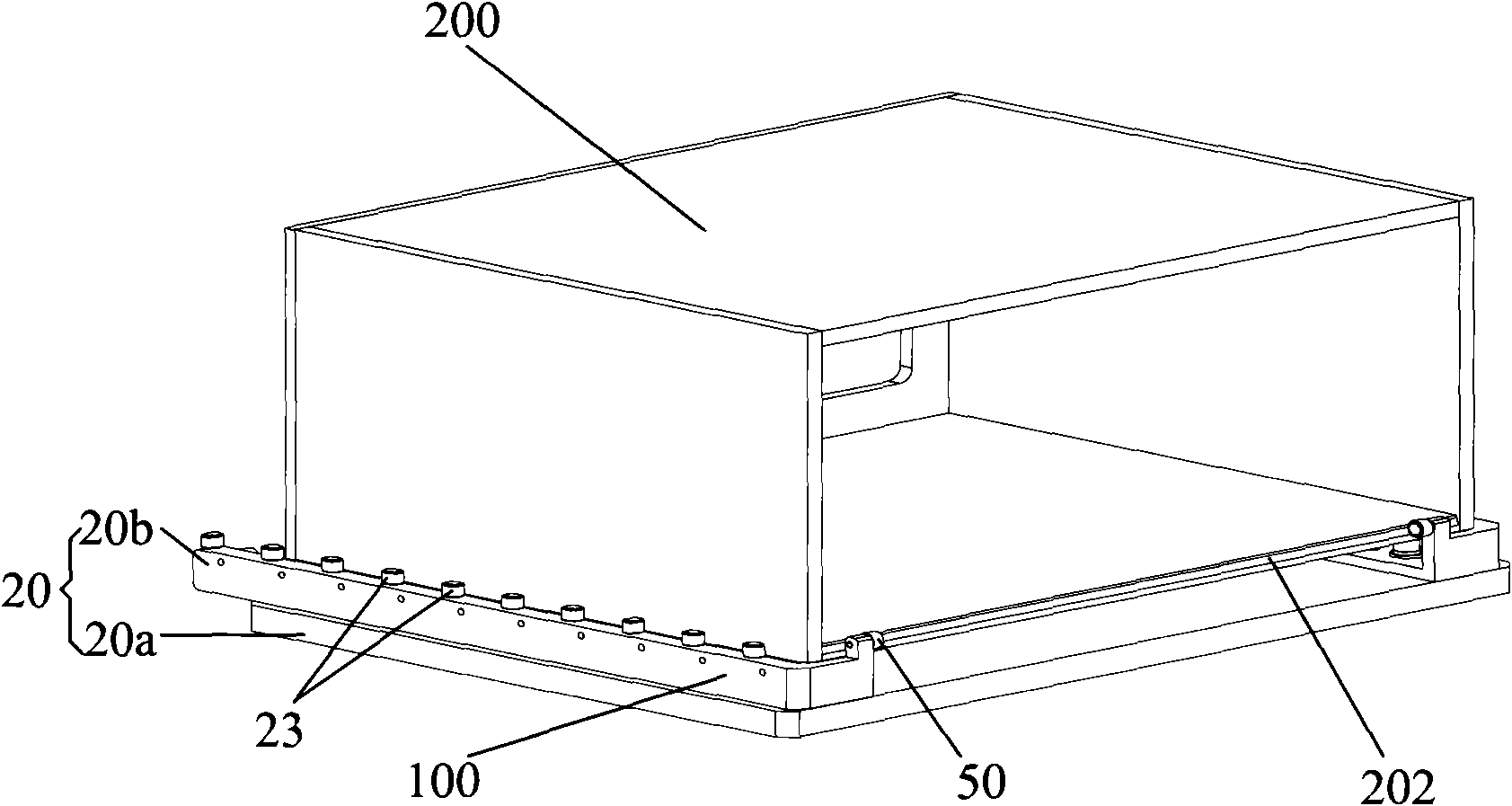

[0025] figure 1 It is an application embodiment of a box clamping mechanism of the present invention, such as Figure 1-4 As shown, in this embodiment, the box 200 is carried on the box clamping mechanism 100 and is in a clamped state. The box clamping mechanism 100 includes a bottom plate 10, two fixing seats 20, a guide block 30, a handle 40 and a limit roller 50, and the two fixing seats 20 are protrudingly fixedly connected to both sides of the bottom plate 10, so The limit roller 50 is connected to the rear end of the fixed seat 20, the guide block 30 is fixedly connected to the front end of the bottom plate 10, and the two sides of the guide block 30 are parallel to each other and have a curved rolling chute 31, sliding rollers 41 are pivotally connected to both sides of the lower end of the handle 40, and the sliding rollers 41 are slidably locked in the rolling chute 31. In this embodiment, the number of sliding rollers 41 There are two, and the matching of multiple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com