Method for leading shield to pass through underground structure

An underground structure and shield technology, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., to achieve the effect of eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

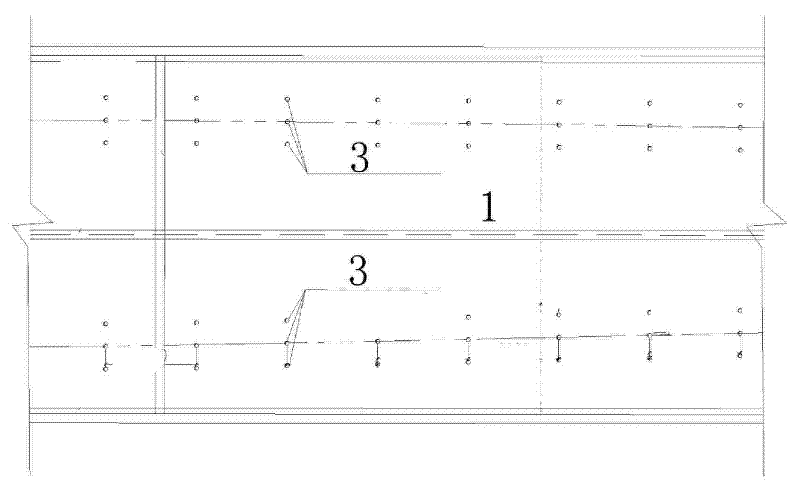

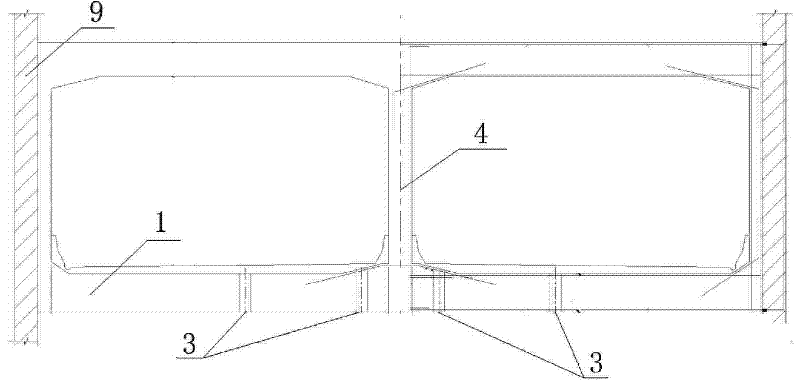

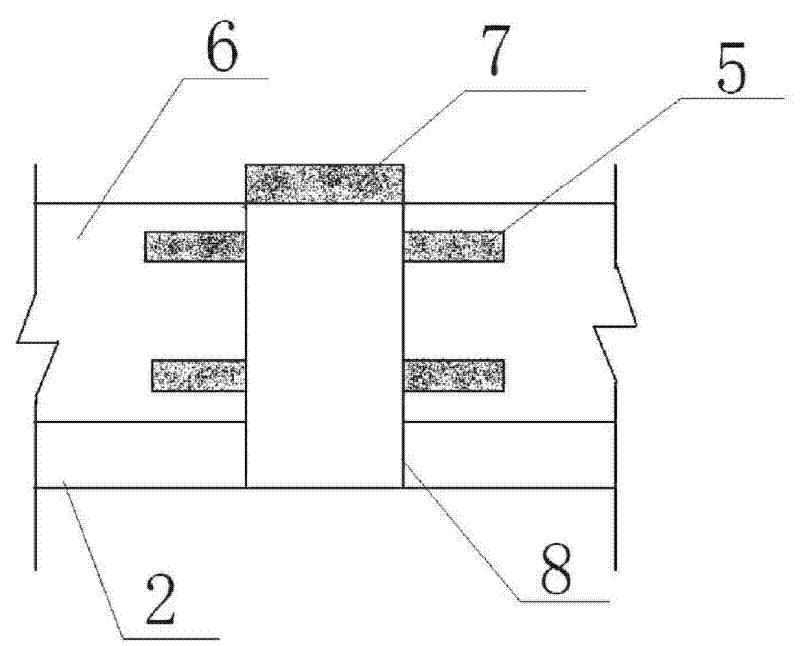

[0025] Such as Figure 1-3 As shown, the numbers 1-9 represent: base plate 1, base plate cushion layer 2, pressure relief hole 3, central column 4, water-stop steel plate 5, reinforced concrete structure 6, head plate 7, steel pipe 8, and ground connection wall 9.

[0026] Such as Figure 1-3 Shown, the construction process of the present invention is as follows:

[0027] 1. Construction of the lower interchange project

[0028] In this construction process, a row of pressure relief holes is reserved every 6m along the axis of the tunnel in the crossed area of the bottom plate 1 of the underground structure. The specific process is as follows:

[0029] 1) When pouring the floor cushion 2, a prefabricated part is used to insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com