Gas cutting-off machine

A cut-off, gas technology, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as poor valve closure, inclusion of impurities in the valve plate or valve body and valve seat, and complex operating procedures. Achieve the effect of avoiding gas leakage, reasonable device structure design, safe and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

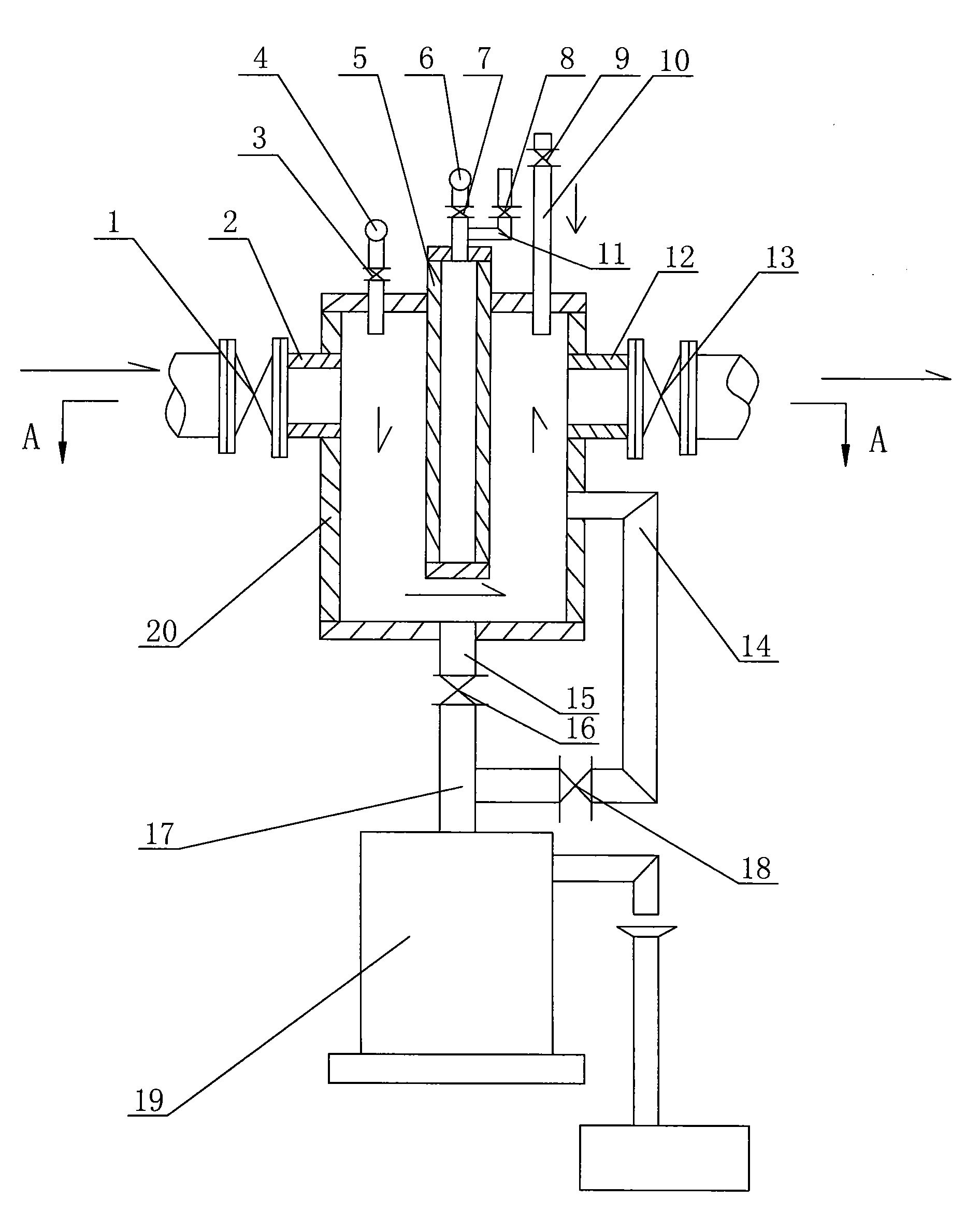

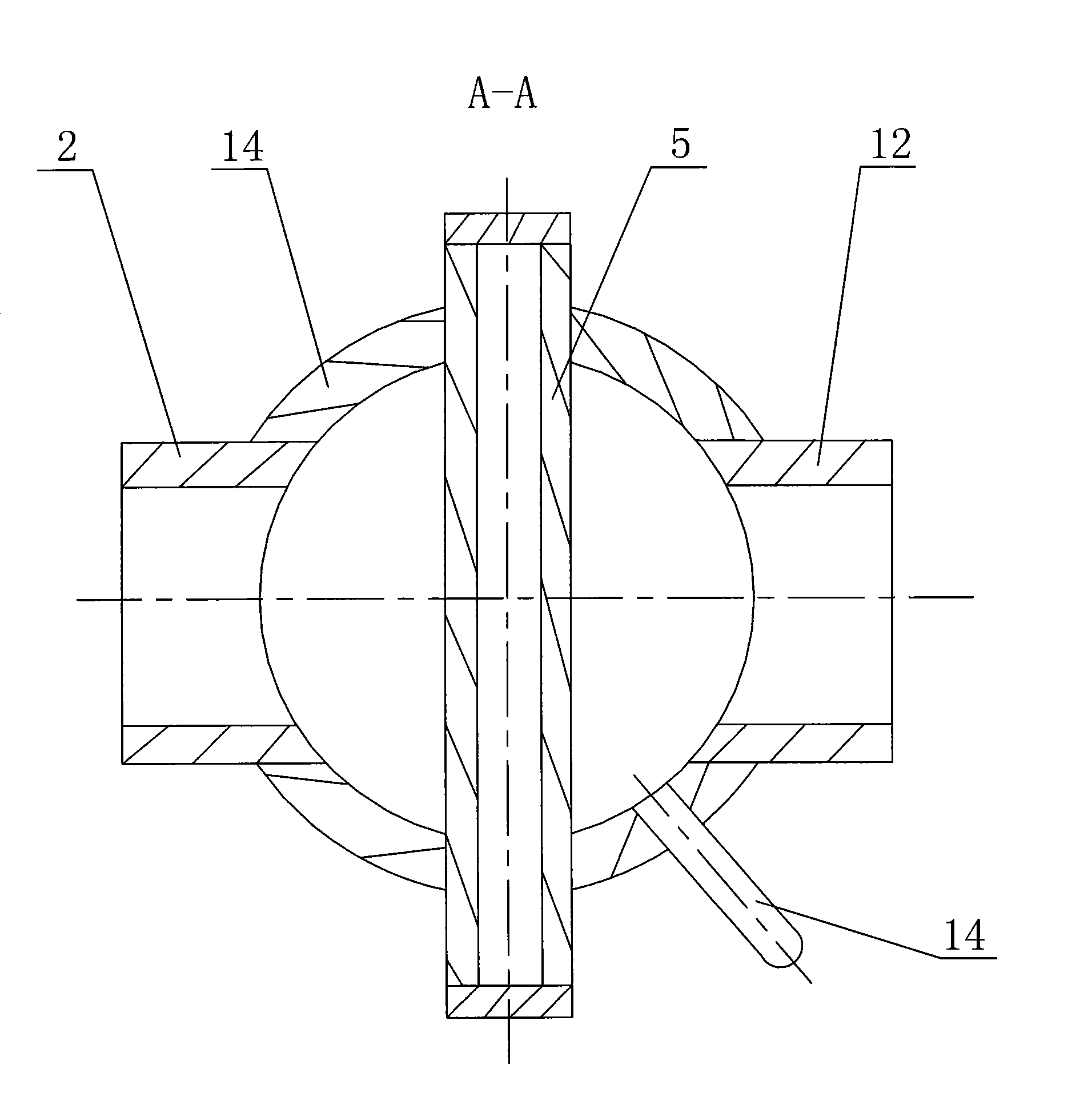

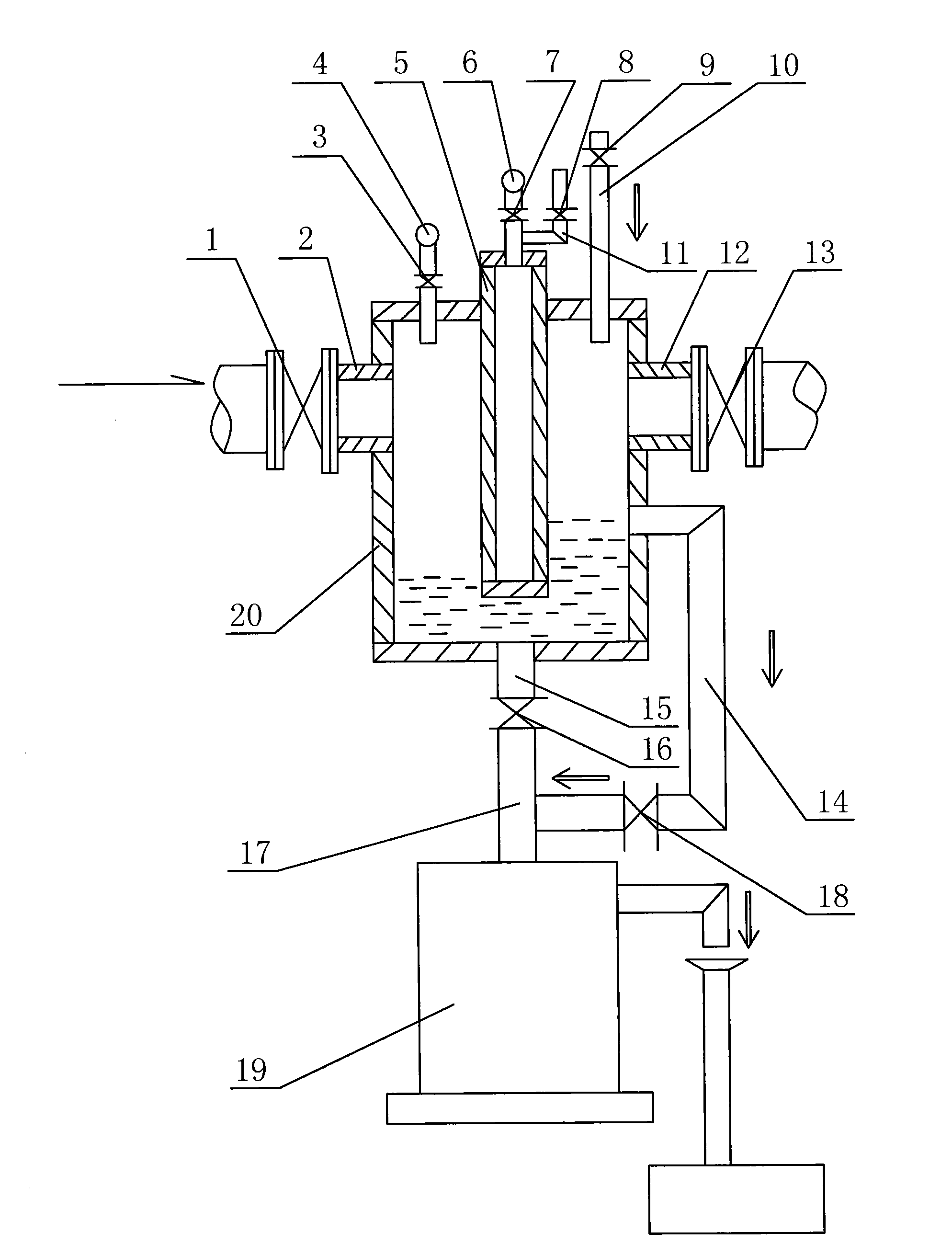

[0018] A gas cut-off device such as Figure 1 ~ Figure 3 As shown, it includes cylinder body 20, dividing plate 5 and water inlet pipe 10, gas inlet pipe 2 and gas outlet pipe 12 are provided on cylinder body 20 both sides, cylinder body 20 middle part is provided with dividing plate 5, dividing plate 5 connects cylinder body 20 Divided into two spaces, an air inlet chamber and an air outlet chamber, the upper part of the cylinder body 20 is provided with a pressure gauge 4 for the air inlet chamber, and the entire cylinder body 20 is in a fully sealed structure. The inside of the partition 5 is a rectangular sealed cavity or a sealed cavity with other shapes. The top and both sides of the partition 5 are respectively exposed outside the cylinder 20. The bottom surface of the partition 5 is lower than the gas inlet pipe 2 and the gas outlet pipe 12 and connected to the cylinder There is a space between the bottoms of the cylinders 20, the part of the partition 5 exposed from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com