Preparation device and preparation method of metallic aluminum coating on surface of carbon fiber

A technology of surface metal and preparation device, which is applied in the directions of carbon fiber, fiber processing, textiles and paper making, etc., can solve the problem of inability to realize continuous preparation of aluminum coating on carbon fiber surface, difficult to effectively control the thickness and uniformity of aluminum coating, and damage to the mechanical properties of carbon fiber. It can improve the surface quality of the coating, prevent the reduction of mechanical properties, and achieve good production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

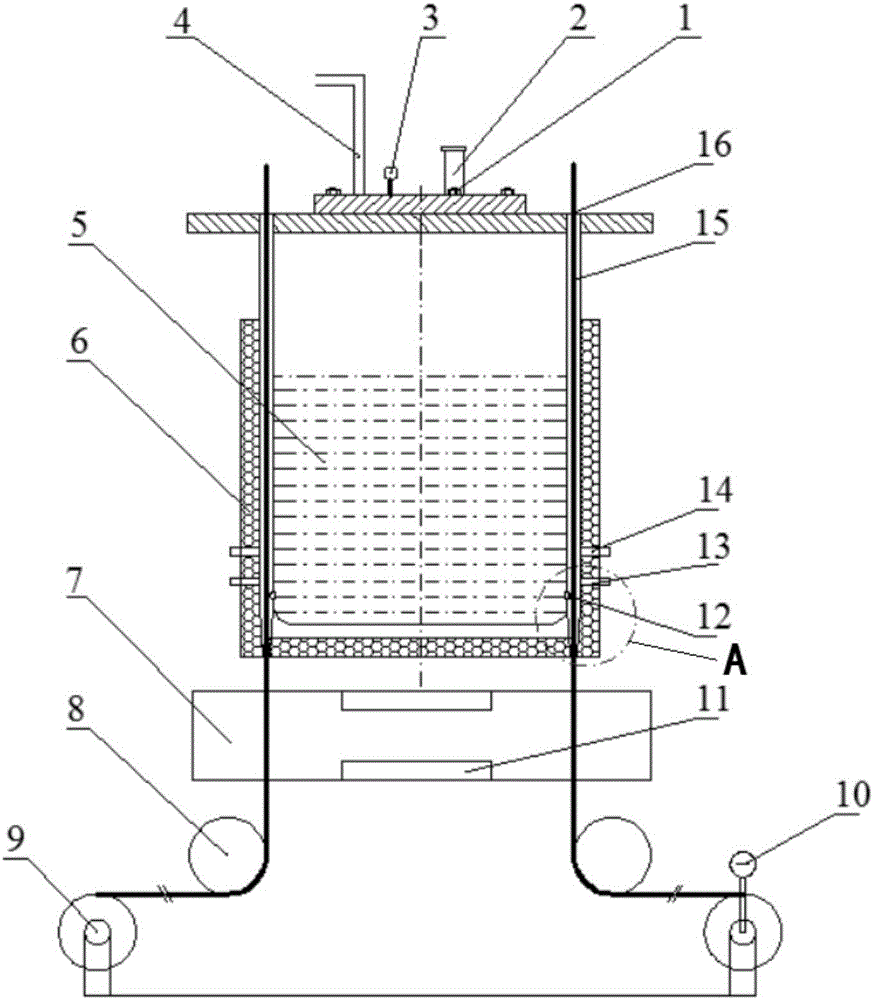

[0036] A method for preparing a metal aluminum coating on a carbon fiber surface, comprising the following steps:

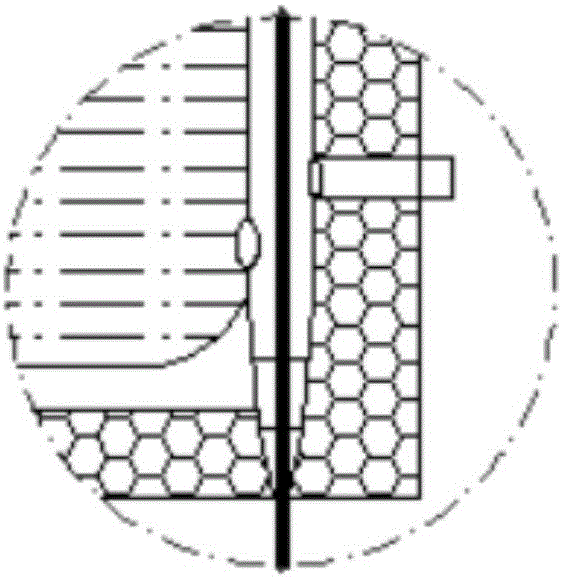

[0037] (1) Close the valve at 12 places of the discharge port or block the discharge port 12, and check the airtightness of the melt tank 5 by first pressurizing and then maintaining the pressure;

[0038] (2) Slowly add the melted aluminum liquid into the melting material tank 5 through the feed port 2, add the molten aluminum liquid to reach two-thirds of the volume of the melting material tank 5, and then stop feeding, and tighten the feeding bolt 1;

[0039] (3) Turn on the cooling element 11 switch to keep the temperature constant after cooling the cooling chamber 7 to the set temperature;

[0040] (4) Observe the speed table 10 and adjust the speed regulator to keep the fiber drawing speed stable to 5.0-10.0mm / s;

[0041] (5) Pass protective argon gas into the axial through hole 15 of the side wall of the molten material tank 5 through the air vent 16;

...

Embodiment 1

[0046] (1) Close the valve at the discharge port 12 at the bottom of the melt tank 5 or block the discharge port 12, first pressurize and then maintain the pressure in the melt tank 5 through the pressurization port 4, and observe the changes in the pressure gauge 3, In order to check the airtightness of the device;

[0047](2) After the air tightness inspection of the device is completed, add a certain amount (two-thirds of the volume of the melting tank 5) of molten aluminum into the melting tank 5 through the feed port 2, and then tighten the feeding Bolt 1;

[0048] (3) Turn on the switch of the cooling element 11, and set the temperature of the cooling chamber 7 to 0°C;

[0049] (4) After the cooling environment reaches the set temperature, open the speed regulator of the roller 9, set the drawing speed of the carbon fiber to 5.0mm / s, slowly increase the drawing speed, and make it steadily reach the set speed value;

[0050] (5) After the fiber filament speed is stable ...

Embodiment 2

[0055] (1) Close the valve at the discharge port 12 at the bottom of the melt tank 5 or block the discharge port 12, first pressurize and then maintain the pressure in the melt tank 5 through the pressurization port 4, and observe the changes in the pressure gauge 3, In order to check the airtightness of the device;

[0056] (2) After the air tightness inspection of the device is completed, add a certain amount (two-thirds of the volume of the melting tank 5) of molten aluminum into the melting tank 5 through the feed port 2, and then tighten the feeding Bolt 1;

[0057] (3) Turn on the switch of the cooling element 11, and set the temperature of the cooling chamber 7 to 0°C;

[0058] (4) After the cooling environment reaches the set temperature, open the speed regulator of the roller 9, set the drawing speed of the carbon fiber to 8.0mm / s, slowly increase the drawing speed, and make it steadily reach the set speed value;

[0059] (5) After the fiber filament speed is stable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com