Electric heating energy-storage recycling system

An electrothermal energy storage, user system technology, applied in the energy industry, heat storage heaters, fluid heaters, etc., can solve the problems of large water consumption, small energy storage, and difficulty in implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

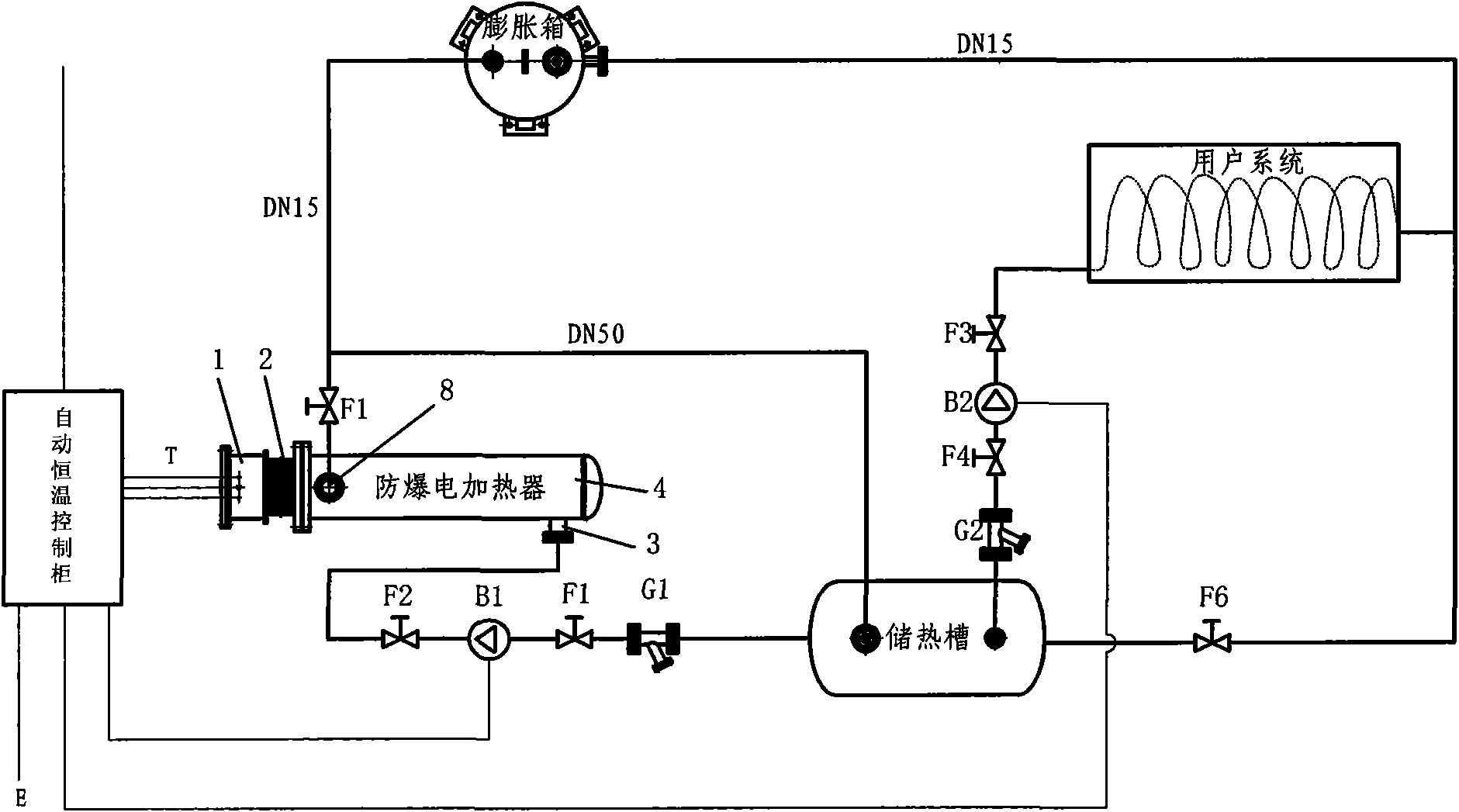

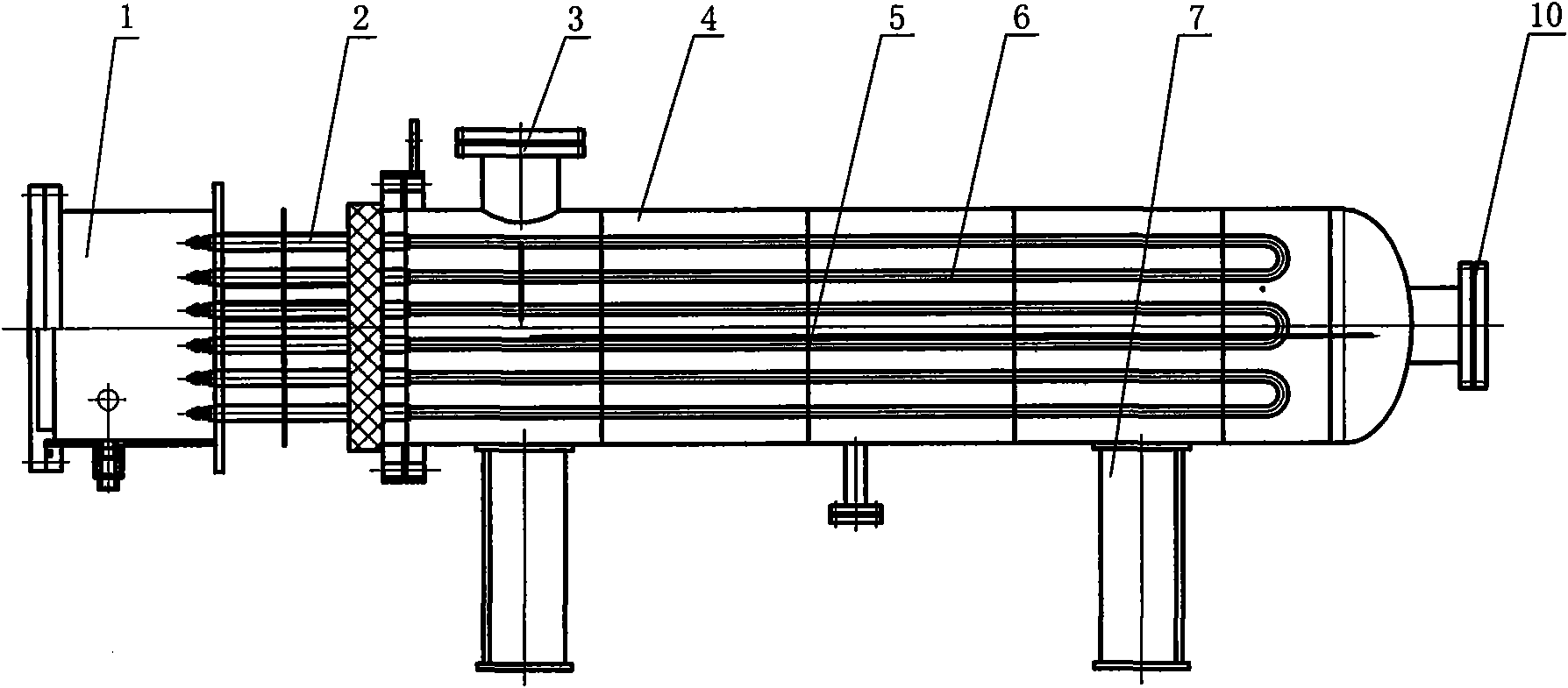

[0016] The electrothermal energy storage recycling system of this embodiment is as follows: figure 1 As shown, it mainly includes heat storage tank, explosion-proof electric heater and expansion tank. The explosion-proof electric heater has a container body 4. One end of the container body is provided with a heat exchange medium inlet 3, and the other end is provided with a heat exchange medium outlet 8. The container body is equipped with an electric heating element connected to an external power supply. The specific structure is as follows: figure 2 As shown, the upper left end of the cylindrical container body 4 placed on the horizontal mounting support 7 is provided with a medium inlet 3 , and the right end is provided with a medium outlet 8 . The end of the container body 4 close to the medium inlet 3 passes through the explosion-proof wiring cavity 1 through the heat dissipation area 2, and a group of electric heating elements 6 extending to the inside of the container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com