Adhesive sheet for optical film, process for production of the adhesive sheet, adhesive optical film, and image display device

一种光学薄膜、制造方法的技术,应用在薄膜/薄片状的粘合剂、没有载体的薄膜/薄片、光学等方向,能够解决无法改善粘合剂层影响等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0139]

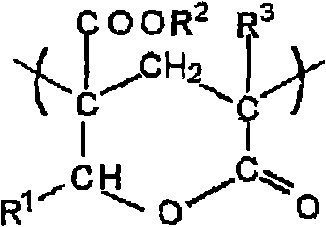

[0140] Put 96.5 parts of butyl acrylate, 3 parts of acrylic acid, 0.5 parts of 2-hydroxyethyl acrylate, 0.15 parts of 2,2'-azobisisobutyronitrile and 100 parts by weight into a four-necked flask equipped with a nitrogen introduction pipe and a cooling pipe. Ethyl acetate, after sufficient nitrogen substitution, was reacted at 60° C. for 8 hours while stirring under a nitrogen stream, and an acrylic polymer solution having a weight average molecular weight of 1.65 million was obtained. With respect to 100 parts of solid content of the above acrylic polymer solution, 0.5 part of isocyanate crosslinking agent (manufactured by Nippon Polyurethane Co., Ltd., Coronet L) was blended to prepare an adhesive coating solution (solid content 12%).

manufacture example 2

[0142]

[0143]Add 99.5 parts of butyl acrylate, 0.5 parts of 4-hydroxybutyl acrylate, 0.15 parts of 2,2'-azobisisobutyronitrile and 100 parts by weight of ethyl acetate into a four-necked flask equipped with a nitrogen introduction pipe and a cooling pipe, After sufficient nitrogen substitution, it reacted at 60 degreeC for 8 hours, stirring under nitrogen stream, and obtained the acrylic-type polymer solution whose weight average molecular weight was 1.65 million. With respect to 100 parts of the solid content of the above-mentioned acrylic polymer solution, 0.2 parts of an isocyanate-based crosslinking agent (manufactured by Nippon Polyurethane Co., Ltd., Coronet L) was blended as a crosslinking agent to prepare an adhesive coating liquid (solid composition is 11.5%).

manufacture example 3

[0145]

[0146] Put 90 parts of butyl acrylate, 4 parts of acrylic acid, 5 parts of acryloyl morpholine, 1 part of 4-hydroxyethyl acrylate, 0.15 parts of 2,2'-azobis Isobutyronitrile and 100 parts by weight of ethyl acetate were fully substituted with nitrogen, and reacted at 60° C. for 8 hours while stirring under nitrogen flow to obtain an acrylic polymer solution with a weight average molecular weight of 1.65 million. With respect to 100 parts of the solid content of the above-mentioned acrylic polymer solution, 0.3 parts of an isocyanate-based crosslinking agent (manufactured by Nippon Polyurethane Co., Ltd., Coronet L) was blended as a crosslinking agent to prepare an adhesive coating liquid (solid composition is 11.5%).

[0147]

[0148] A polyvinyl alcohol film having a thickness of 80 μm was stretched 5 times in an iodine aqueous solution and then dried to obtain a polarizing plate. A transparent protective film (triacetyl cellulose film, 80 μm in thickness) was b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com