Translucent structure

A technology of light transmission and structure, applied in the direction of optics, light source, electric light source, etc., can solve the problem of image visual recognition reduction, and achieve the effect of suppressing the reduction of visual recognition and low haze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach }

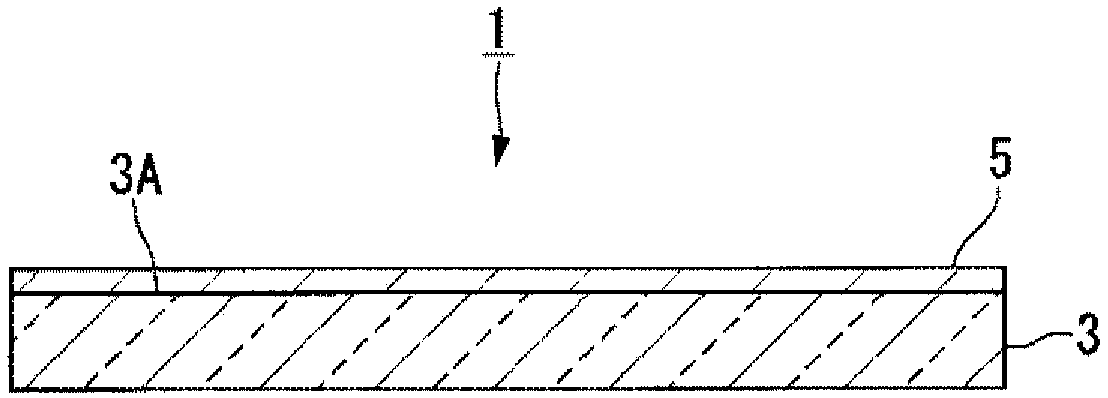

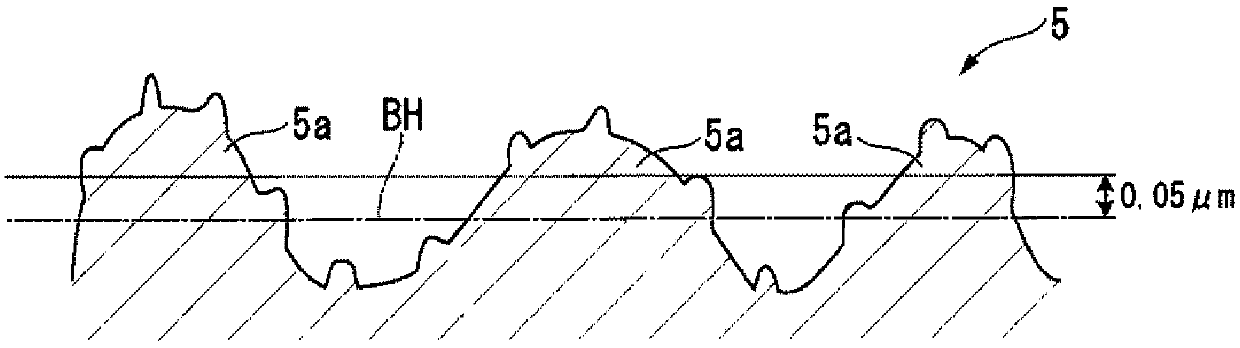

[0058] figure 1 Among them, the translucent structure 1 of this embodiment has the translucent base material 3 and the antiglare layer 5 formed on the first surface 3A. The antiglare layer 5 has a concavo-convex structure on the surface. The surface of the antiglare layer 5 constitutes the surface of the translucent structure 1 . Therefore, the translucent structure 1 has a concavo-convex structure on the surface. It should be noted, figure 1 In this example, the ratio of the thickness of the anti-glare layer 5 to the thickness of the light-transmitting base material 3 is larger than the actual ratio for the sake of convenience.

[0059] (translucent substrate)

[0060] As the translucent base material 3, any base material may be used as long as it can transmit visible light, and a transparent base material is preferable. Transparency in the light-transmitting substrate 3 means that light in the wavelength range of 400 nm to 1100 nm transmits an average of 80% or more (av...

no. 2 approach }

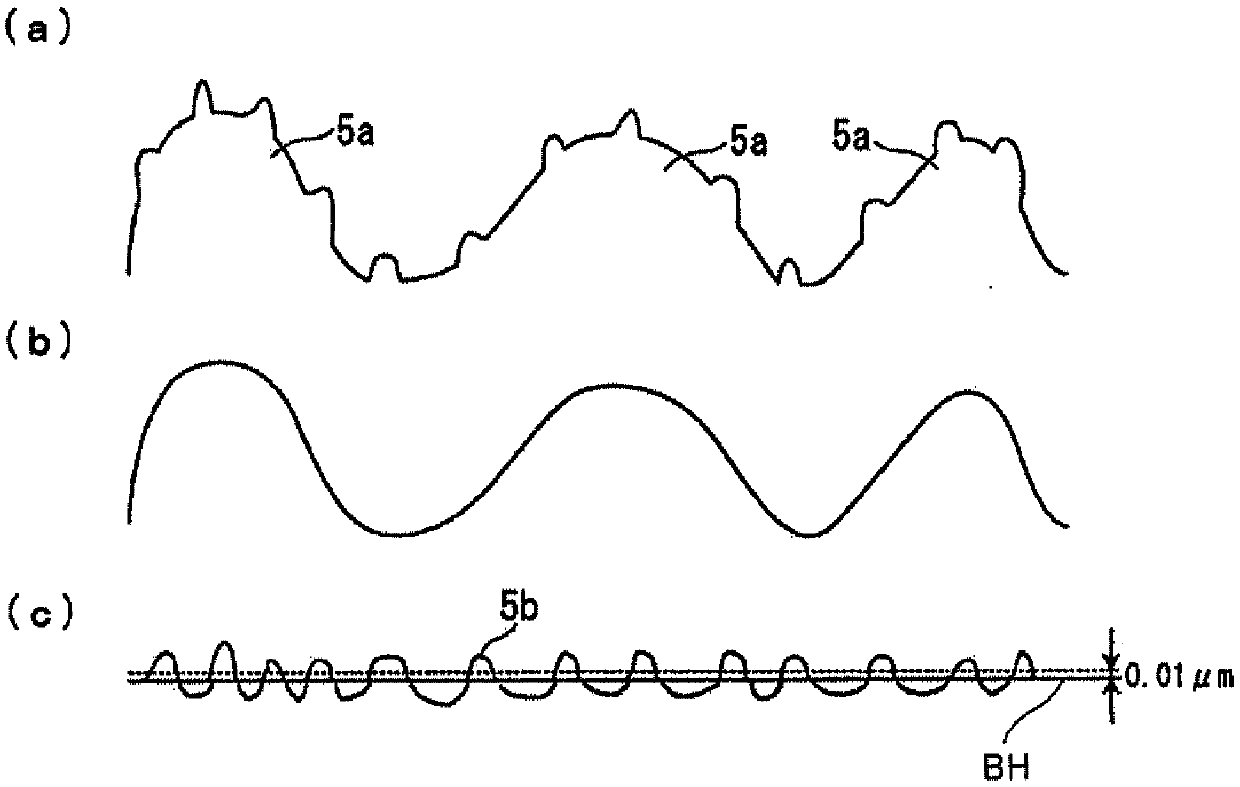

[0184] Figure 4 It is a schematic cross-sectional view showing the translucent structure 2 according to the second embodiment of the present invention. Figure 5 It is a diagram illustrating the relationship between the surface shape of the light-transmitting structure 2 , its smoothed image, and an image obtained as a difference of their XYZ data.

[0185] The translucent structure 2 of the present embodiment has a translucent base material 4 . The translucent substrate 4 has a concavo-convex structure on the first surface 4A. The first surface 4A of the translucent substrate 4 constitutes the surface of the translucent structure 2 . Therefore, the translucent structure 2 has a concavo-convex structure on the surface.

[0186] The light-transmitting base material 4 is the same as the light-transmitting base material 3 of the first embodiment except that the first surface has a concavo-convex structure, and the preferred form is also the same.

[0187] The uneven structur...

no. 3 approach }

[0199] Figure 6 It is a cross-sectional view schematically showing the translucent structure 6 according to the third embodiment of the present invention. Figure 7 It is a cross-sectional view schematically illustrating the structure near the surface of the translucent structure 6 . In addition, in the embodiment shown below, the same code|symbol is attached|subjected to the component corresponding to the said embodiment, and detailed description is abbreviate|omitted.

[0200] The translucent structure 6 of the present embodiment has a translucent substrate 3 , an antiglare layer 5 formed on the first surface 3A of the translucent substrate 3 , and an antireflection layer formed on the antiglare layer 5 7 (functional layer), and the water and oil repellent layer 9 (functional layer) formed on the anti-reflection layer 7. The antireflection layer 7 and the water and oil repellent layer 9 each have a concavo-convex structure on the surface similarly to the antiglare layer 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com