Electric measuring tape

A tape measure and electric technology, applied in the direction of the bendable ruler, etc., can solve the problem that the tape is not fast enough to enter and exit, the winding is not very compact, and the tape is damaged, so as to eliminate the phenomenon of "swelling tape", enter and exit quickly and smoothly, and change small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

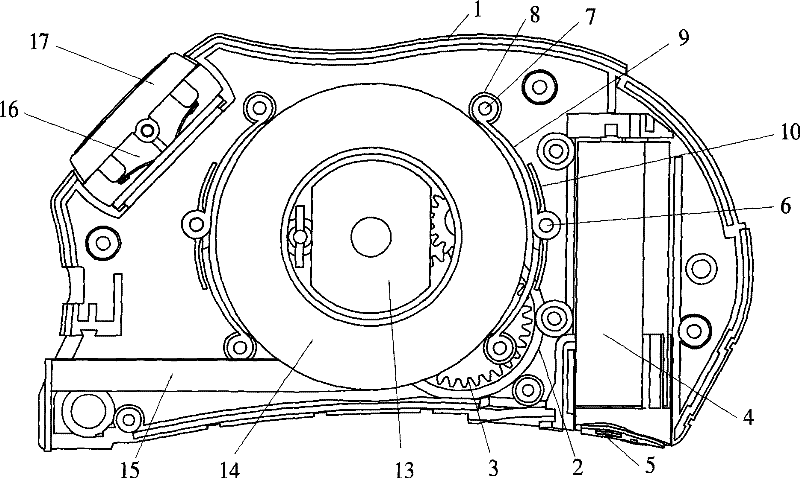

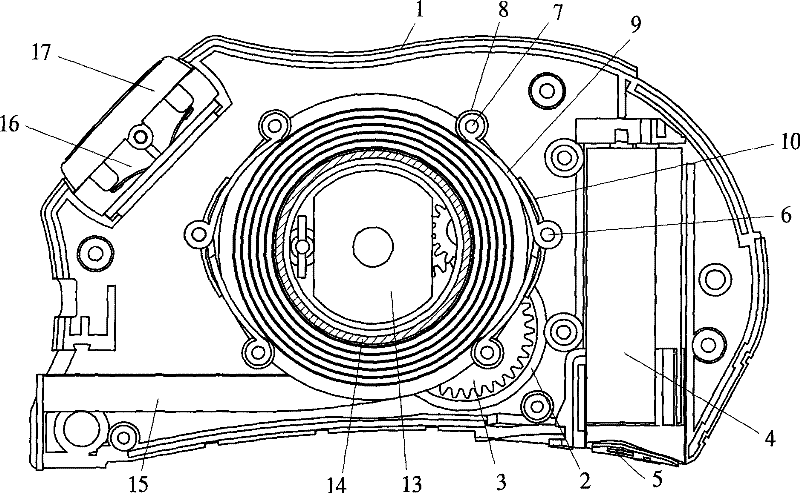

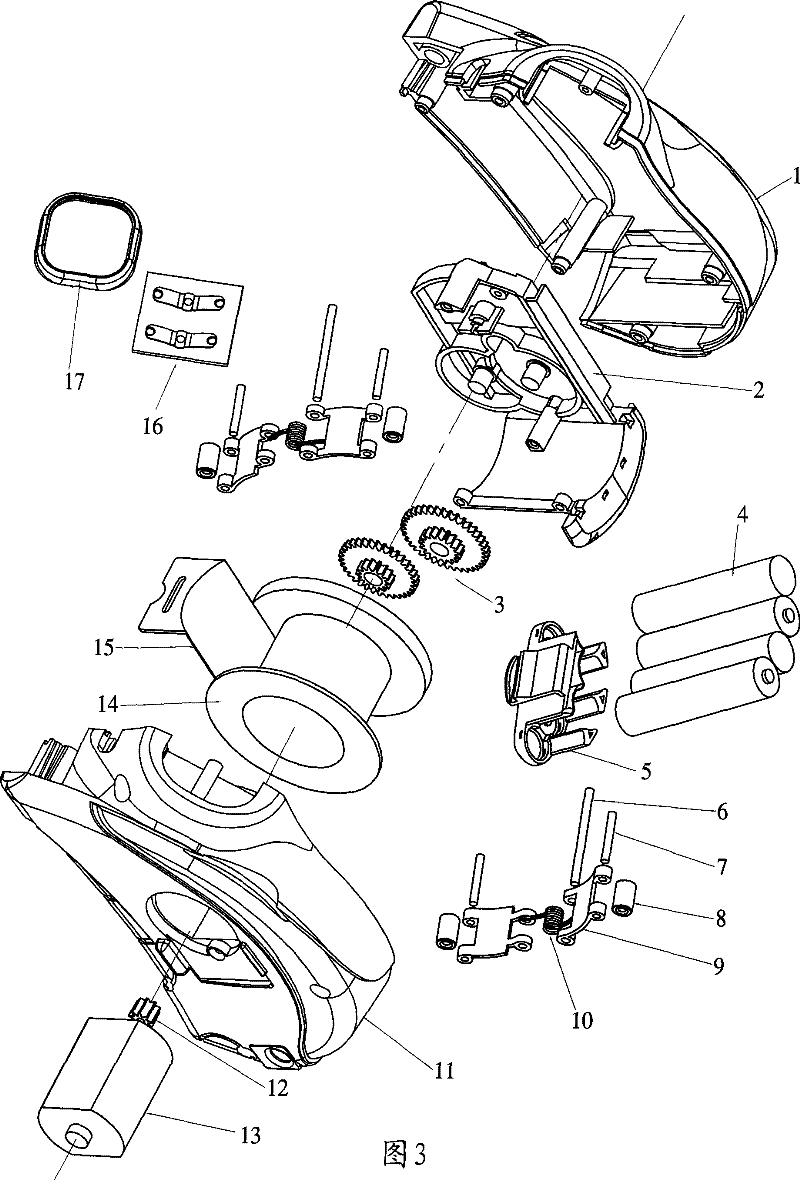

[0033] Example 1: Reference figure 1 , figure 2 , image 3 and Figure 4 As shown, the electric tape measure in this embodiment includes a scale housing, a scale core disc 14, a motor 13, a battery 4, a switch 16, a transmission mechanism and an automatic tightening mechanism.

[0034] The scale shell is composed of the regular scale shell 1 and the reverse scale shell 11, and has accommodating space. The scale core disc 14 is rotatably arranged in the middle cavity of the scale shell and is wound with a scale tape 15.

[0035] The motor 13 is located in the scale housing, and is linked with the scale core disc 14 through a transmission mechanism to realize the extension and retraction of the scale tape. Angle, the mouth that forms scale shell to accommodate electric motor 13 cavity like this is big and the bottom is little, and motor 13 can guarantee the cooperation precision and the accuracy of motor 13 and scale shell by packing into outside scale shell.

[0036] Switc...

Embodiment 2

[0042] Example 2: Reference Figure 5 As shown, the driving member of the automatic tightening mechanism in this embodiment adopts the reed 9a, and the reed 9a acts as a rotating arm.

[0043] The reed 9a is generally in the shape of a herringbone, and the intersecting transition part of the reed 9a is rotatably arranged on the inner wall of the scale housing through a reed shaft 6a, and the reed shaft 6a is wrapped with an open bushing to play a protective and position-limiting effect. There are two rollers 8, which are respectively rotatably arranged on the bifurcated end of the reed 9a through the roller shaft 7, and the roller 13 abuts against the tape 15 on the ruler core disc 14 under the self elastic force of the reed 9a. Other structures and working principles are the same as in Embodiment 1.

Embodiment 3

[0044] Example 3: Reference Figure 6 As shown, the driving part of the automatic clamping mechanism in this embodiment adopts a compression spring 10a, one end of the compression spring 10a is connected to the outer side of the rotating arm 9, and the other end is connected to the protrusion 1a on the inner wall of the scale housing. Other structures and working principles are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com