Design method of high tension coil of dry on-load coarse and fine voltage regulation transformer

A technology of high-voltage coil and design method, applied in the direction of transformer/inductor coil/winding/connection, transformer, variable transformer, etc., can solve the problems of large impedance voltage deviation, large lateral magnetic flux leakage, difficult control of partial discharge amount, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

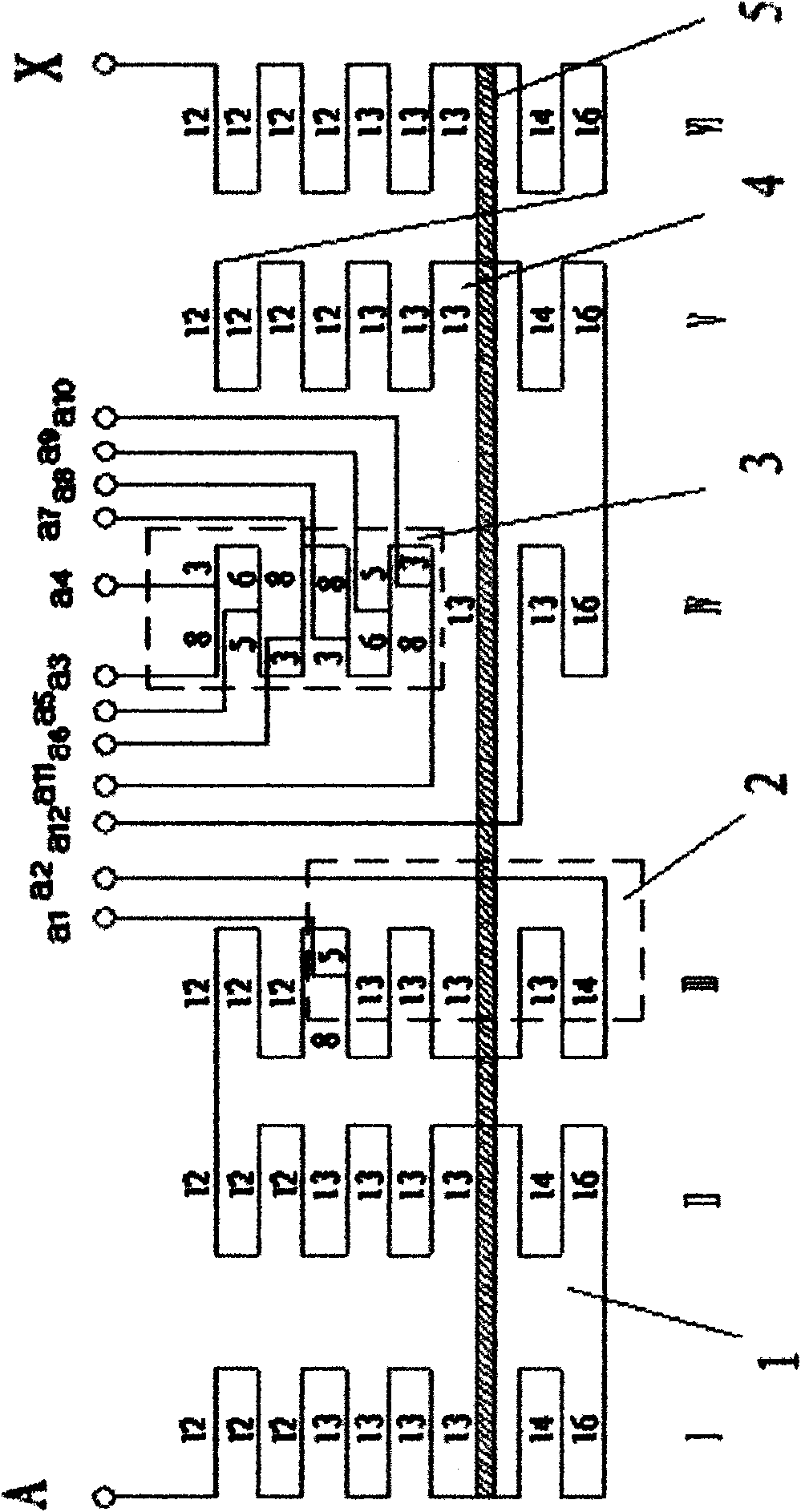

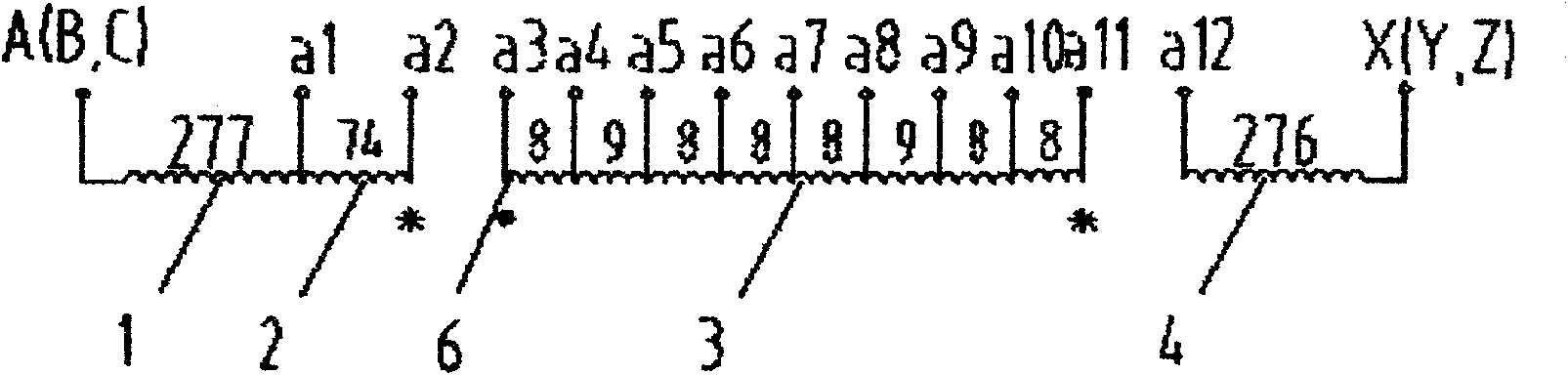

[0018] The present invention will be further described now in conjunction with accompanying drawing, wherein figure 2 and image 3 What is described is that its rated capacity is 1250kVA, its rated high voltage is 11kV, and its voltage regulation range is -15~+5%, which is 11 -12 +4 ×1.25%kV high-voltage coil, the coil is wound with polyimide enameled wire, the thickness of the paint film is 0.16mm, the thickness of the inner and outer envelope insulation of the coil is 3mm, and the vacuum resin is poured and then cured and formed.

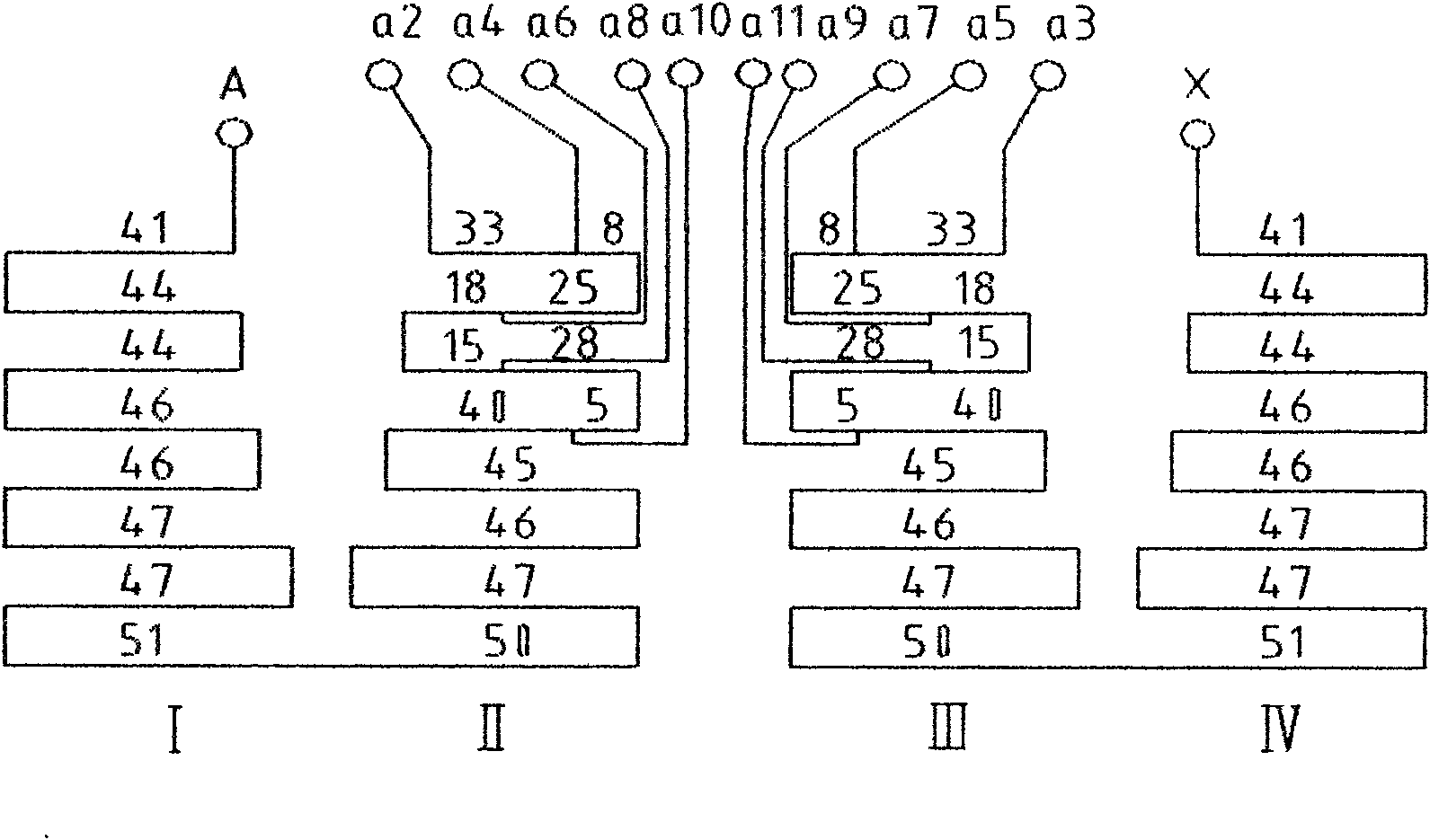

[0019] Such as figure 2 As shown, it is different from the conventional two-stage and four-stage voltage regulation structure with a voltage level of 10kV (see figure 1 ), this example uses a six-section structure, and is divided into normal turns zone 1, coarse turns zone 2, fine turns zone 3 and normal turns zone 4. Between the normal turns area 1 and 4, a coarse turn area 2 and a fine turn area 3 are connected in series. The coarse-tunin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com