Elastic fibre laying die, laying device comprising such a die, and use of said device

A laying and fiber technology, applied in the field of laying devices, can solve the problems of complicated preform methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

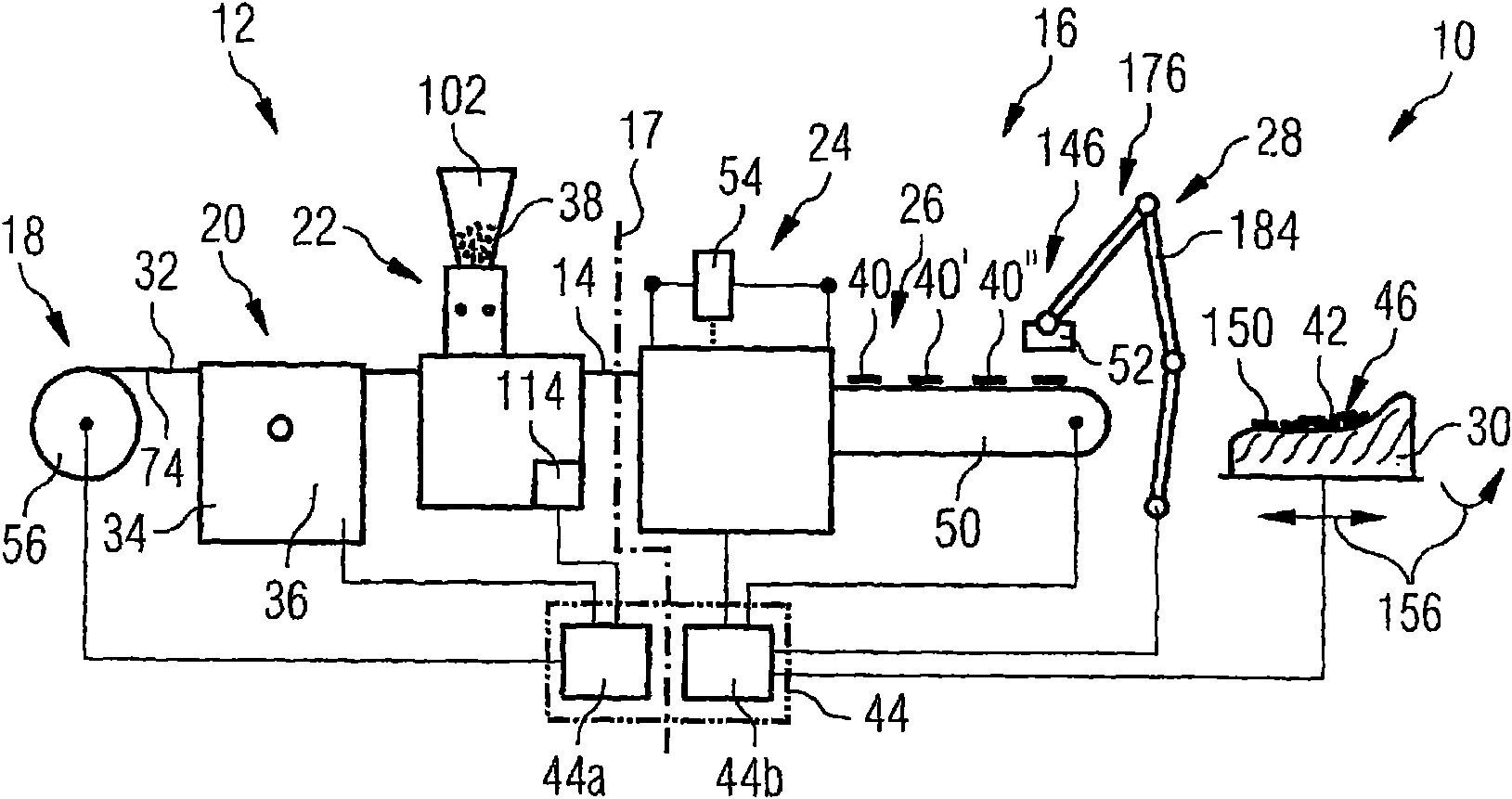

[0045] figure 1 A general view of the preform manufacturing plant, generally indicated by reference numeral 10, is shown. The preform production device allows complex textile semi-finished products to be produced from fiber filaments aligned in the load flow, so that fiber composite structures can be produced in a simple manner even in the case of semi-finished products with complex structures. This textile semi-finished product is called a preform. These preforms consist of individual staple fiber segments held in place by a binder material in accordance with figure 1 Manufactured in advanced equipment, these fiber segments can be pre-cut from specially pretreated fiber tows or fiber tapes. Thus, the preform manufacturing plant may comprise a preparation module 12 for possible preparation of the fiber tape 14 and a cutting and laying module 16 for cutting and laying the fiber tape segments. A possible demarcation 15 between modules 12 and 16 is indicated by a dotted line. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com