Short fiber jet orientation forming process

A molding process and short fiber technology, which is applied in the field of short fiber spray orientation molding technology, can solve the problems of high input cost, low production efficiency, inconsistent flow speed, etc., achieve cost advantages, improve production efficiency, and facilitate mass production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

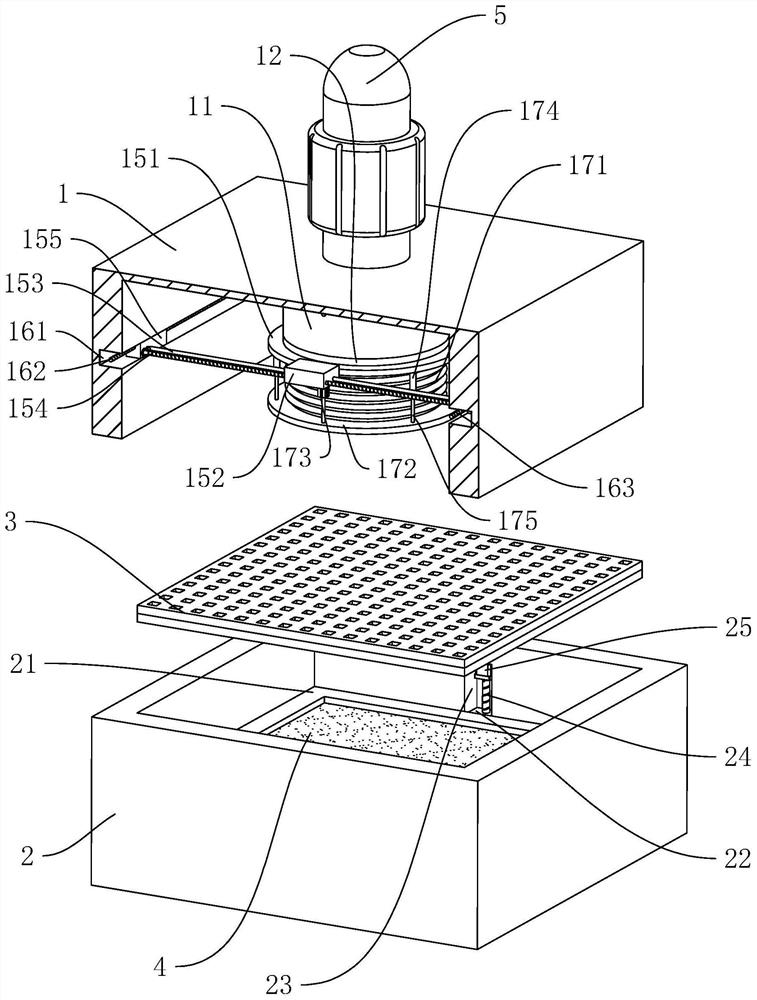

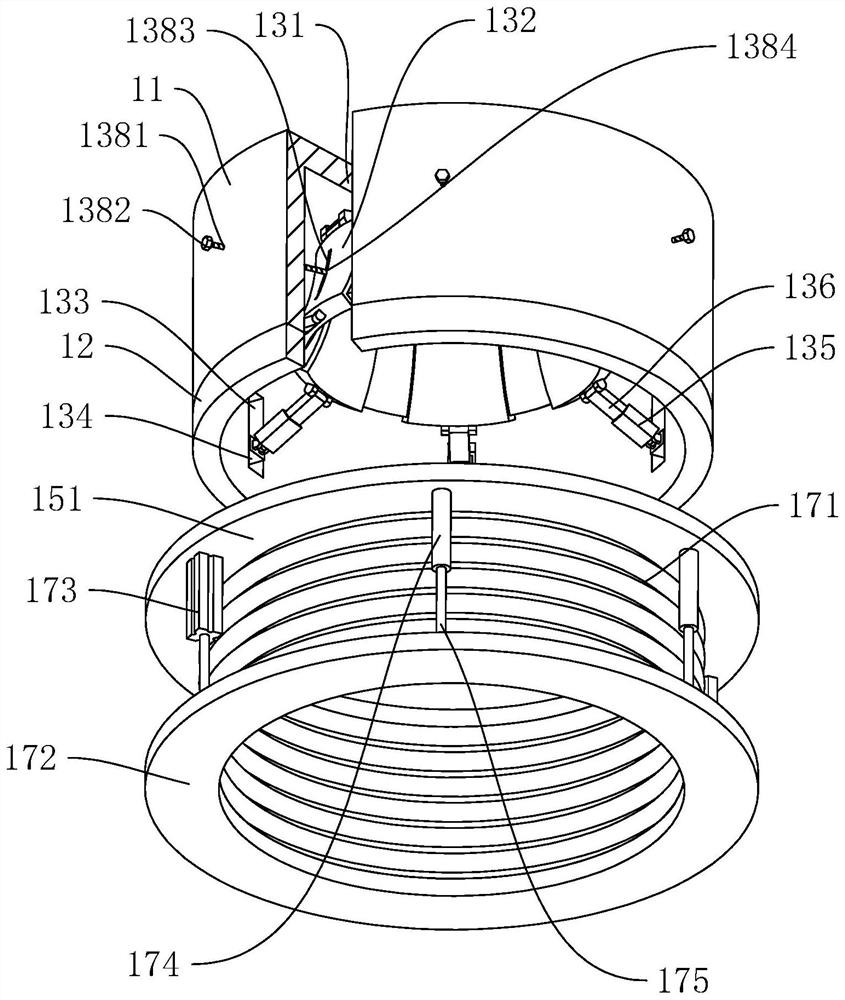

[0043] The following is attached Figure 1-6 The application is described in further detail.

[0044] The embodiment of the present application discloses a forming process of short fiber spray orientation.

[0045] refer to figure 2 , including: S1: Preparation of semi-crosslinked carrier 4.

[0046] S2: installing the semi-crosslinked carrier 4 , installing the semi-crosslinked carrier 4 on the installation frame 21 .

[0047] S3: Start the short fiber spray orientation device, spray the short fiber to the semi-crosslinked carrier 4 for orientation and shaping, and form a product surface with an area of 150*150mm.

[0048] S31: Install short fibers on equipment with spraying function. The loading barrel has a blast function, which can preliminarily disperse short fibers and prevent agglomeration. There are more than two layers of filter screens in the spraying device, which can further restrain short fibers The injection state ensures that the length of the short fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com