A 3D printing electromagnetic absorbing concrete directional fiber graded feeding system

An electromagnetic wave absorbing and 3D printing technology, which is applied in mixed operation control, clay preparation device, mixed operation control device, etc., can solve the problems of missing the strength of steel fiber concrete, waste of steel strength of concrete, and lack of orientation process of steel fiber, etc. The effect of improving mechanical strength, enhancing tensile strength, and enhancing electromagnetic wave absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

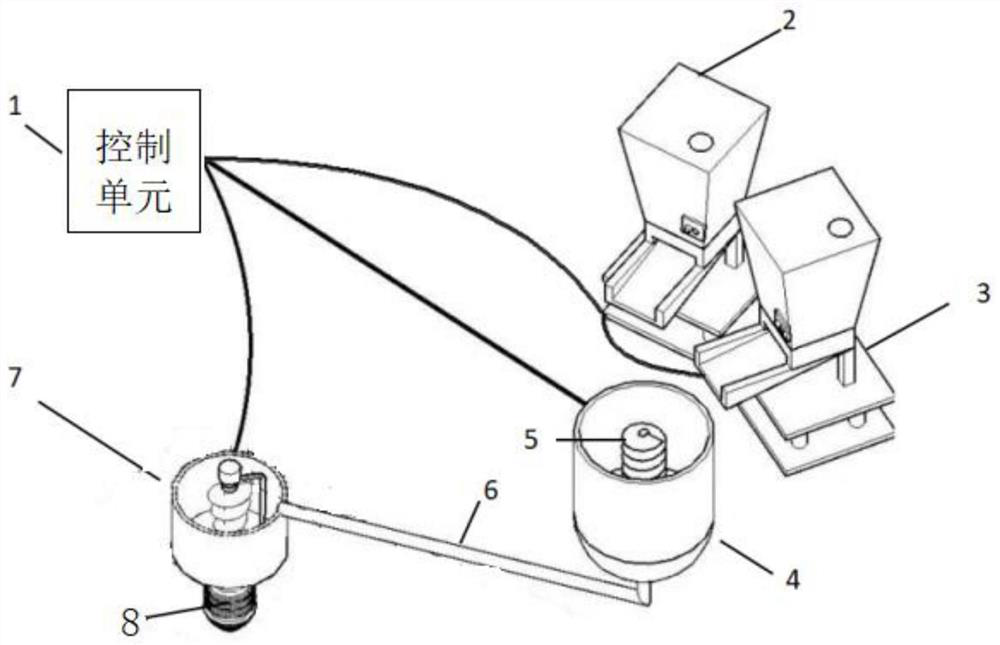

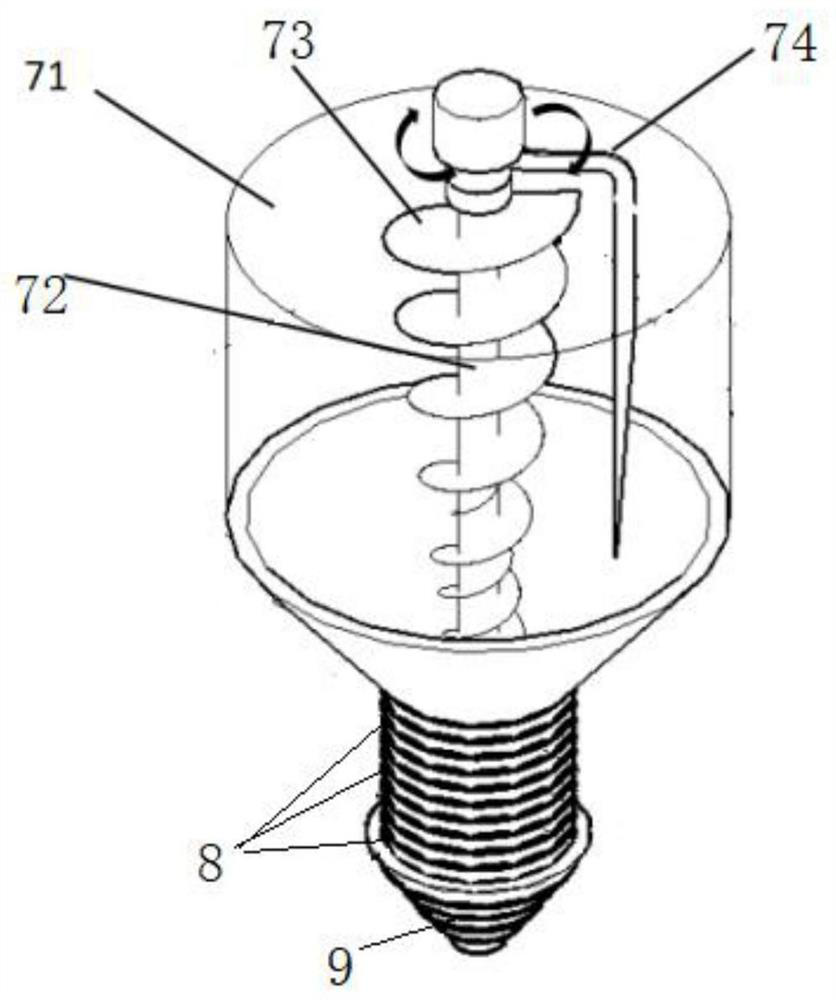

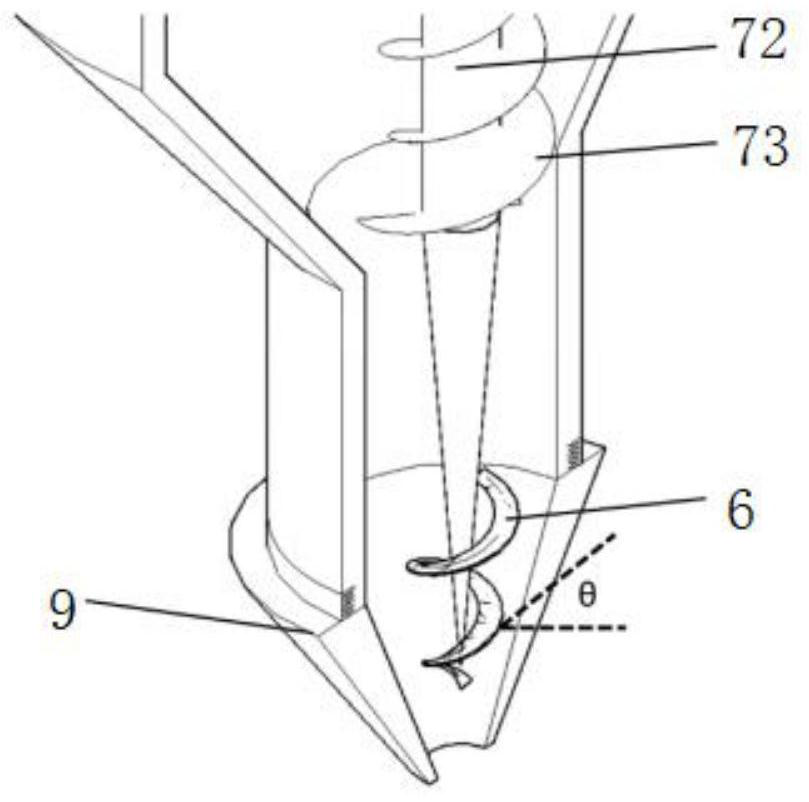

[0033] The system of this embodiment includes a control unit 1, a dry material storage mechanism 2, a wet material storage mechanism 3, a large mixing tank 4, a stirring impeller 5, a secondary mixing unit 7, a protection resistor, a switch, a current control knob, a DC power supply, a spiral Pipe 8, detachable nozzle 9, three-stage stirring impeller 6. The secondary stirring unit includes a medium-sized mixing tank 71, an impeller shaft 72, a medium-sized impeller 73, an auxiliary impeller and a coaxial reverse device 74 thereof.

[0034] The lower part of the medium-sized mixing tank 71 is a rotator whose cross-section gradually decreases. The impeller shaft 72 is arranged along the axial direction of the medium-sized mixing tank. A medium-sized impeller is arranged on the impeller shaft 72 in the medium-sized mixing tank. Shaft reverse device, the side of the coaxial reverse device is fixedly connected with the auxiliary impeller, the coaxial reverse device is opposite to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com