Carbon nanotube fiber composite material, its preparation method and application

A carbon nanotube fiber, carbon nanotube technology, applied in fiber processing, fiber chemical characteristics, cellulose/protein conjugated rayon, etc. The material cannot meet the multi-functional requirements of smart textiles and clothing, and achieve the effect of excellent electrical conductivity and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

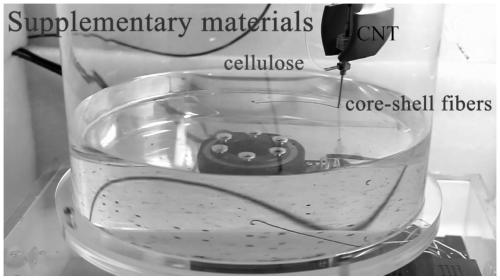

[0046] A method for preparing a carbon nanotube fiber composite material provided by an embodiment of the present invention comprises the following steps:

[0047] S1. Preparation of internal spinning solution

[0048] The carbon nanotube spinning solution is an internal spinning solution, which is used to form an inner layer structure during coaxial spinning. The internal spinning solution is obtained by mixing carbon nanotubes and concentrated sulfuric acid. On the one hand, concentrated sulfuric acid can be used as a dispersant for carbon nanotubes, and on the other hand, it can also provide an acidic environment during cellulose regeneration.

[0049] Preferably, the mixing process is to stir for 0.5-1.5 h first, and then filter after ultrasonic treatment for 20-50 min. The carbon nanotubes can be uniformly dispersed in the concentrated sulfuric acid by first stirring and then ultrasonic treatment, and the dispersibility of the carbon nanotubes in the cellulose can be imp...

Embodiment 1

[0074] The present embodiment provides a kind of preparation method of carbon nanotube fiber composite material, it comprises the following steps:

[0075] First, a 1 wt% MWCNTs dispersion was prepared. By adding MWCNTs to concentrated H 2 SO 4 and stirred at room temperature (about 25 °C) for 1 h, then sonicated (100 W, 30 min) using a KQ-50DE water bath sonicator, and then the mixture was passed through a 30 μm syringe filter to remove aggregates.

[0076] Next, a 4 wt% cellulose solution was prepared. First, 11.68 g of urea was added to 29.2 mL of 40 wt % TBAH solution (V TBAH :m urea =1:0.4), and stirred at 180 rpm for 30 minutes. Then 1.72 g of α-cellulose was added to the above solution and stirred for 1 hour to prepare a uniform solution to prepare a 4 wt% cellulose solution. Finally, the prepared 4 wt% cellulose solution was centrifuged at 5000 rpm for 10 min to remove air bubbles.

[0077] Finally, coaxial spinning. Concentrated sulfuric acid (H 2 SO 4 ) and...

Embodiment 2

[0079] The present embodiment provides a kind of preparation method of carbon nanotube fiber composite material, it comprises the following steps:

[0080] First, a 0.5wt% MWCNTs dispersion was prepared. By adding MWCNTs to concentrated H 2 SO 4 and stirred at room temperature (about 25 °C) for 0.5 h, then sonicated (100 W, 20 min) using a KQ-50DE water bath sonicator, and then the mixture was passed through a 30 μm syringe filter to remove aggregates.

[0081] Next, a 3 wt% cellulose solution was prepared. First, 8.76 g of urea was added to 29.2 mL of 35 wt % TBAH solution (V TBAH :m urea =1:0.3), and stirred at 180 rpm for 30 minutes. Then α-cellulose was added to the above solution and stirred for 1 hour. Finally, the prepared cellulose solution was centrifuged at 4000 rpm for 15 min to remove air bubbles.

[0082] Finally, coaxial spinning. Concentrated sulfuric acid (H 2 SO 4 ) and sodium sulfate (Na 2 SO 4 ) dissolved in deionized water (H 2 SO 4 : Na 2 SO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com