Method for manufacturing multi-layer magnetic core

A technology of magnetic core and core layer, applied in the direction of magnetic core manufacturing, magnetic core/yoke, inductor/transformer/magnet manufacturing, etc., can solve the problems of small size, difficult operation, and the film does not have high mechanical rigidity, so as to achieve flexibility. effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

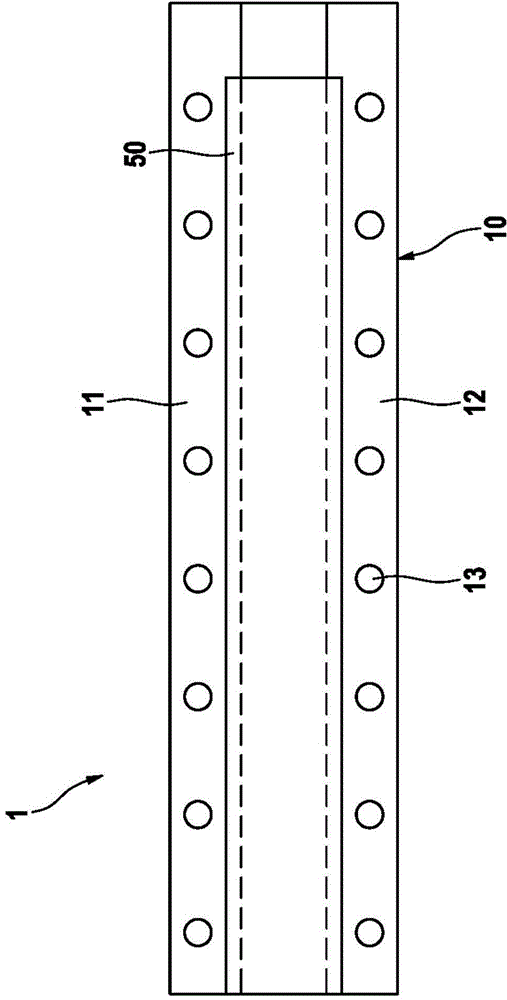

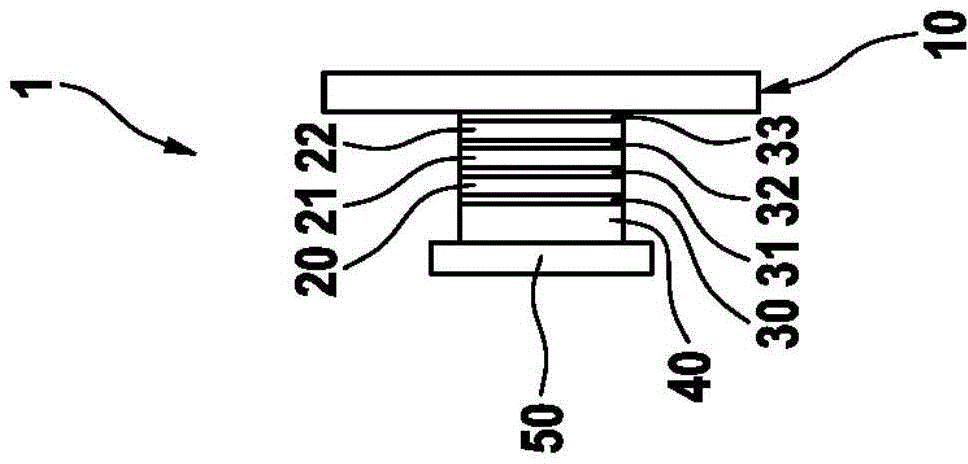

[0048] Figure 1a and 1b A multilayer magnetic core 1 according to the first embodiment is shown. The core can be used in inductive sensors, in particular in the linear position sensors produced by the applicant.

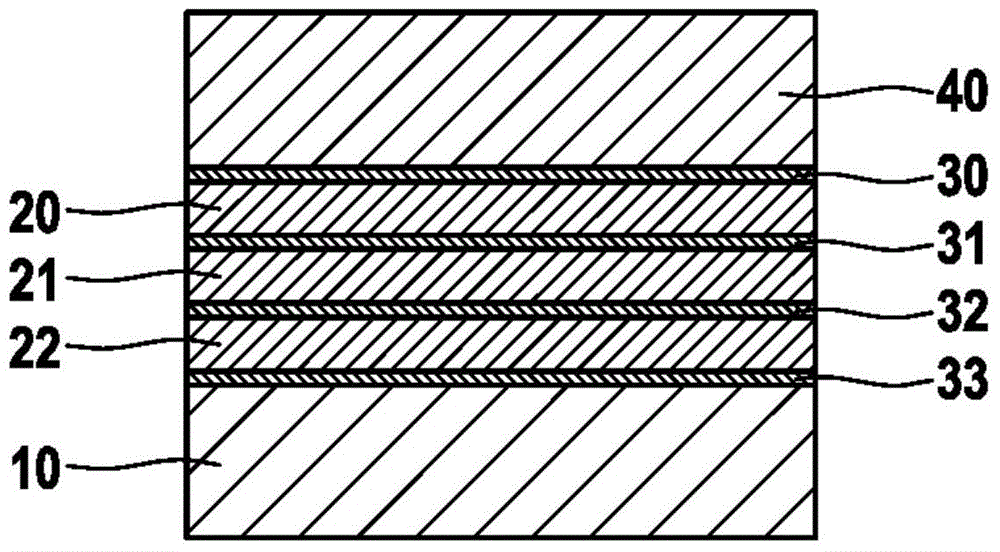

[0049] The core 1 has an outer layer 10 on which a plurality of core layers 20 , 21 , 22 are placed, wherein the outer layer 10 is designed to support and protect the core layers. The core layer 22 is fastened to the outer layer 10 by means of a connecting medium 32 . The other core layers 20 , 21 are connected to adjacent core layers 20 , 21 , 22 by means of connecting media 31 , 32 . An electrically conductive layer 40 is placed on the core layer 20, but this layer is not required. Furthermore, the core 1 has a separation layer 50 as a secondary outer layer.

[0050]The core layers 20, 21, 22 are made of materials with soft magnetic properties. In particular, the material of the core layers 20 , 21 , 22 is chosen such that the core layers do not have magnetos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com