Machine room chute

A technology for cable racks and machine rooms, which is applied in the direction of pipe supports, mechanical equipment, electrical components, etc., which can solve the problems of scratches and bruises on the coating, heavy weight, and affect the appearance, and achieve convenient installation, large carrying capacity, and reduced difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with accompanying drawing:

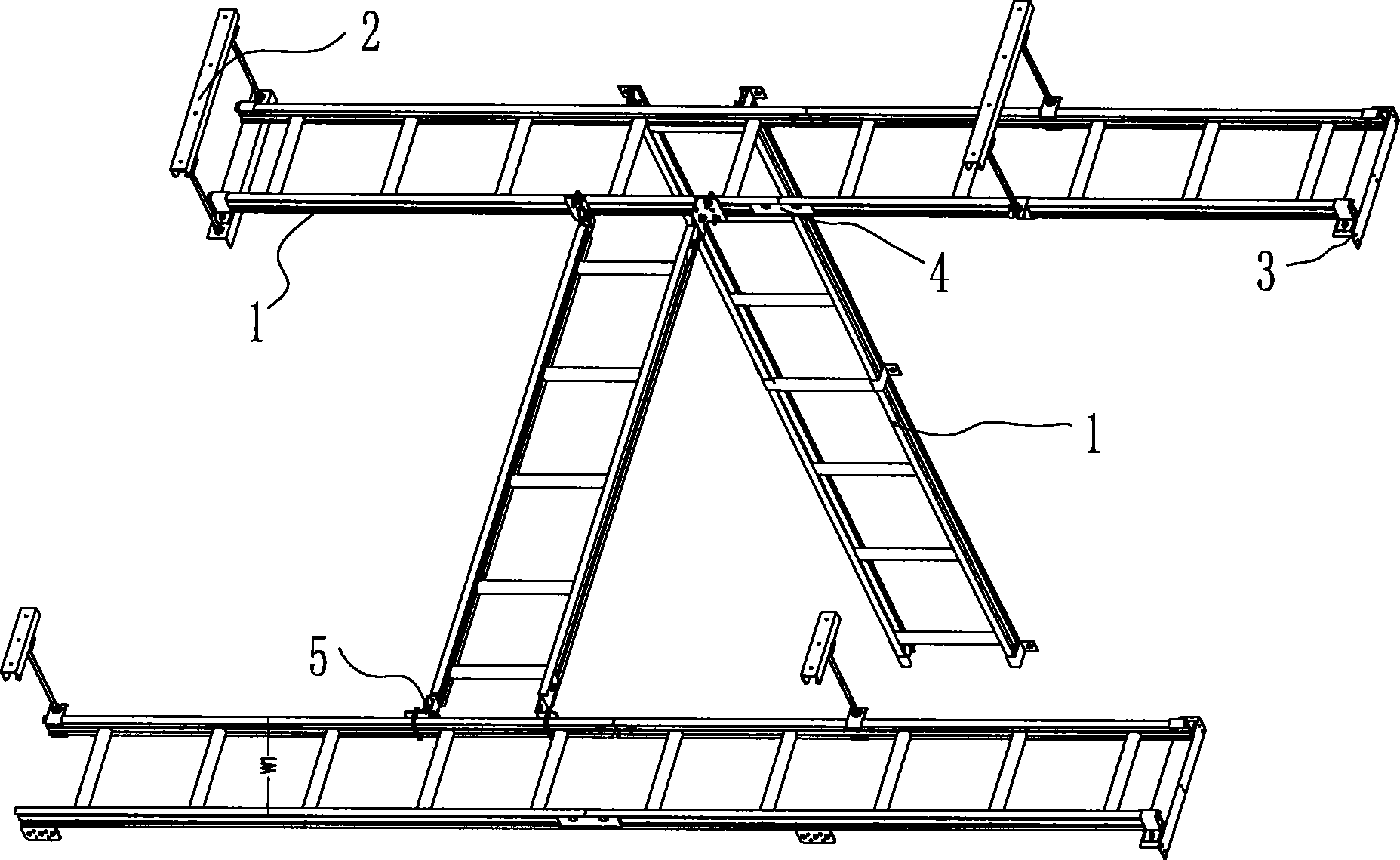

[0047] see figure 1 As shown, the cabling rack in the machine room is made of a wire rack 1 made of aluminum profiles; It is composed of a straight connecting plate 4 for horizontal connection between one wire frame and a corner connection component 5 for vertical connection between two wire frames. The cable tray made of aluminum profile is easy to process and can be cut according to the required length.

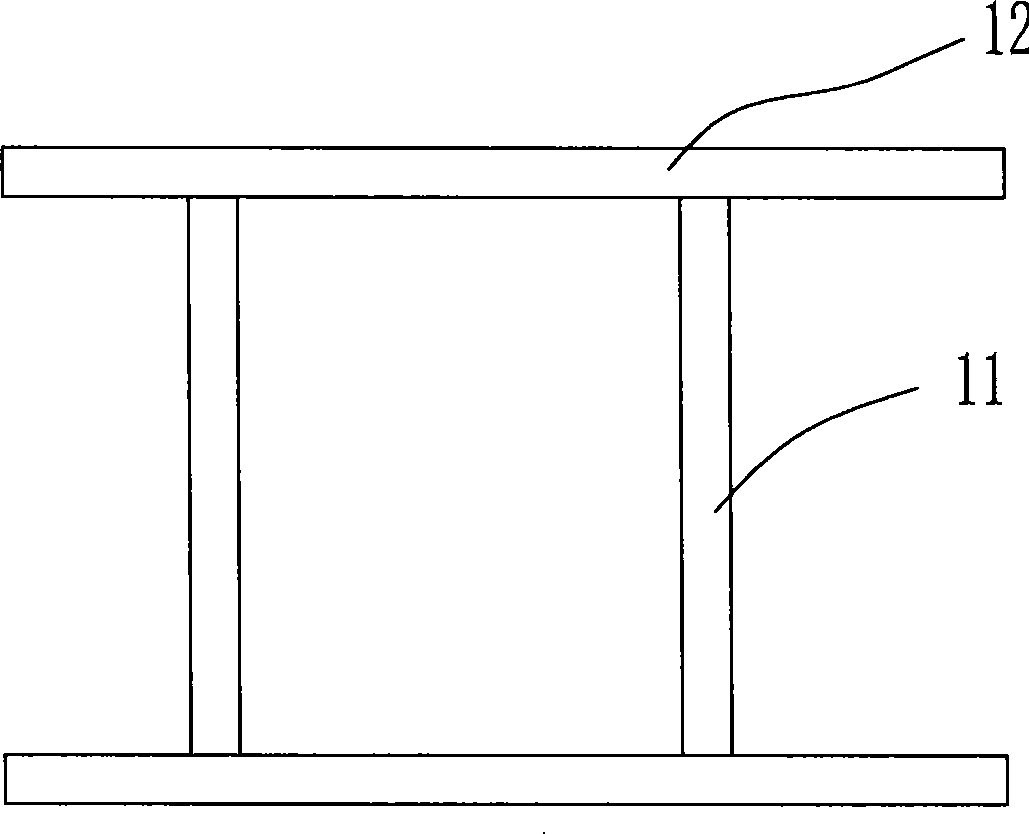

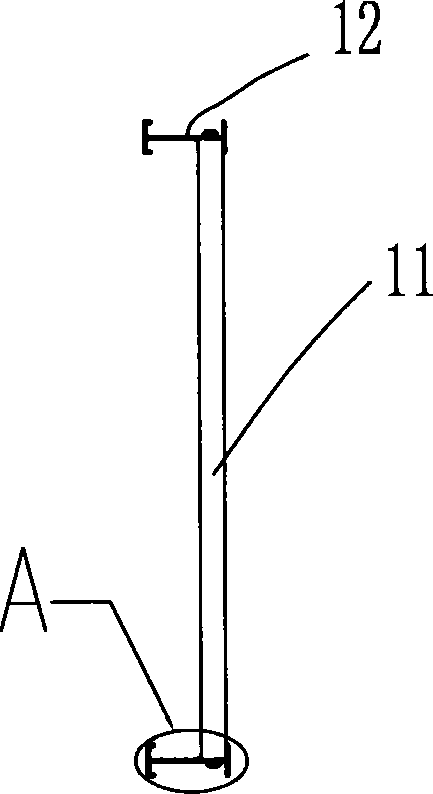

[0048] see figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the wire frame 1 is composed of a central beam 11 and a main beam 12 vertically fixed by self-tapping screws 13 at both ends thereof.

[0049] The main girder 12 consists of a section bar 121 in an H-shaped frame, an E-shaped frame 1211 whose two ends of a longitudinal side protrude inward and are parallel to the horizontal side, and a straight line between the middle beam 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com