Motor structure assembly

A technology of structural components and motors, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve problems such as structural space and structural size restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

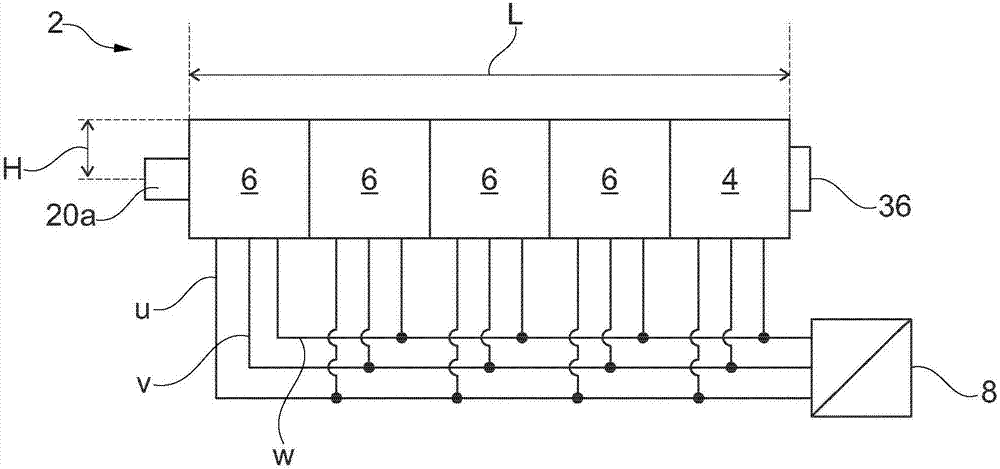

[0030] exist figure 1The motor subassembly 2 of a not-shown adjustment drive of the rack handling device is shown schematically in simplified form. The elongated motor assembly 2 comprises a servomotor 4 arranged on the end side and four electric motors 6 arranged one behind the other. The motors 4 and 6 of the motor assembly 2 are electrically and mechanically coupled to each other. The motors 4 and 6 , which are preferably embodied as brushless electric motors, are energized during operation with three motor phases u, v, w and are connected in parallel to a common converter 8 for this purpose.

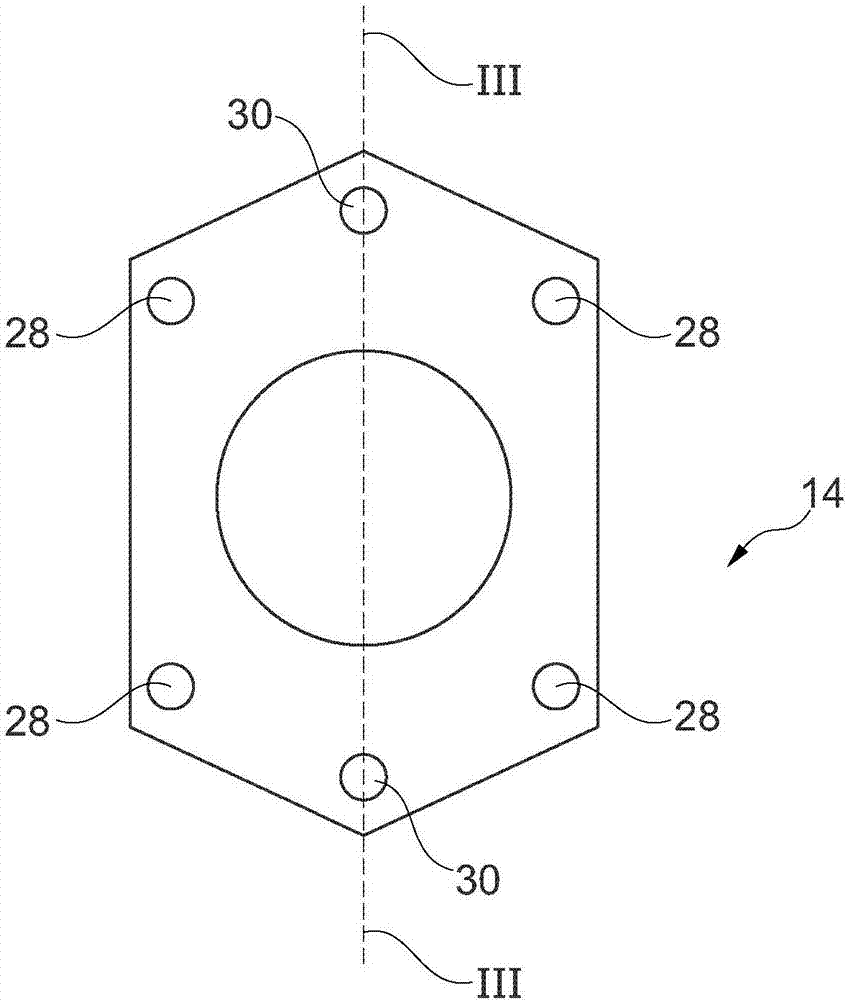

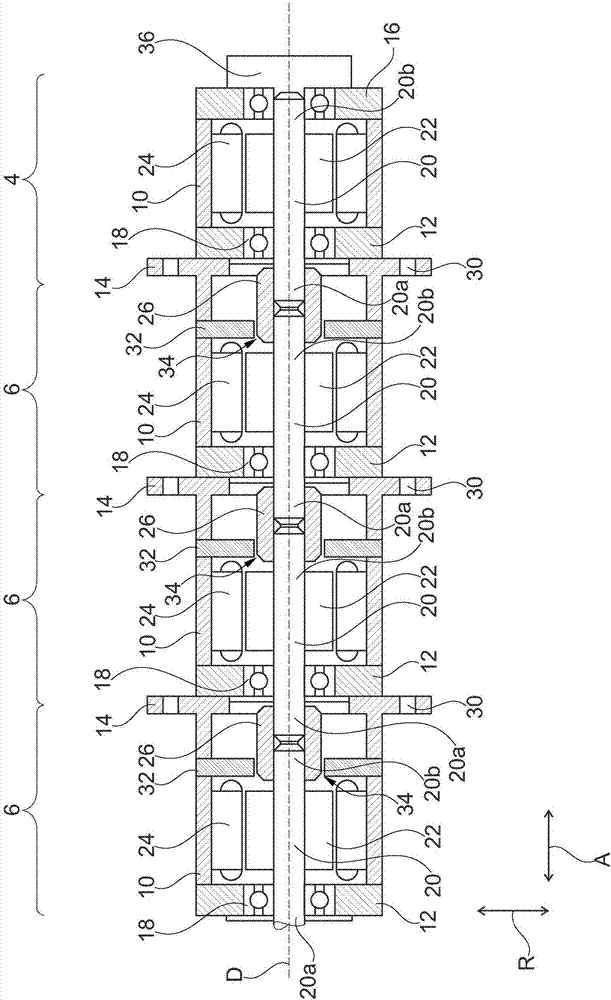

[0031] figure 2 The motor subassembly 2 is shown in section with an axial direction A and a radial direction R. The section extends along a common axis of rotation D of the motors 4 and 6 , which is oriented parallel to the axial direction A. The radial direction R is oriented here in particular along the shaft height H of the motor subassembly 2 , wherein the axial direction A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com