Web conveyance controlling method, web slip amount measuring means, and web conveyance controlling device

A technology of conveying control and measurement unit, which is applied in the direction of transportation and packaging, thin material handling, winding strips, etc. It can solve problems such as thin strip sliding, thin strip wrinkling, and inability to control the horizontal position of thin strips, so as to reduce the offset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

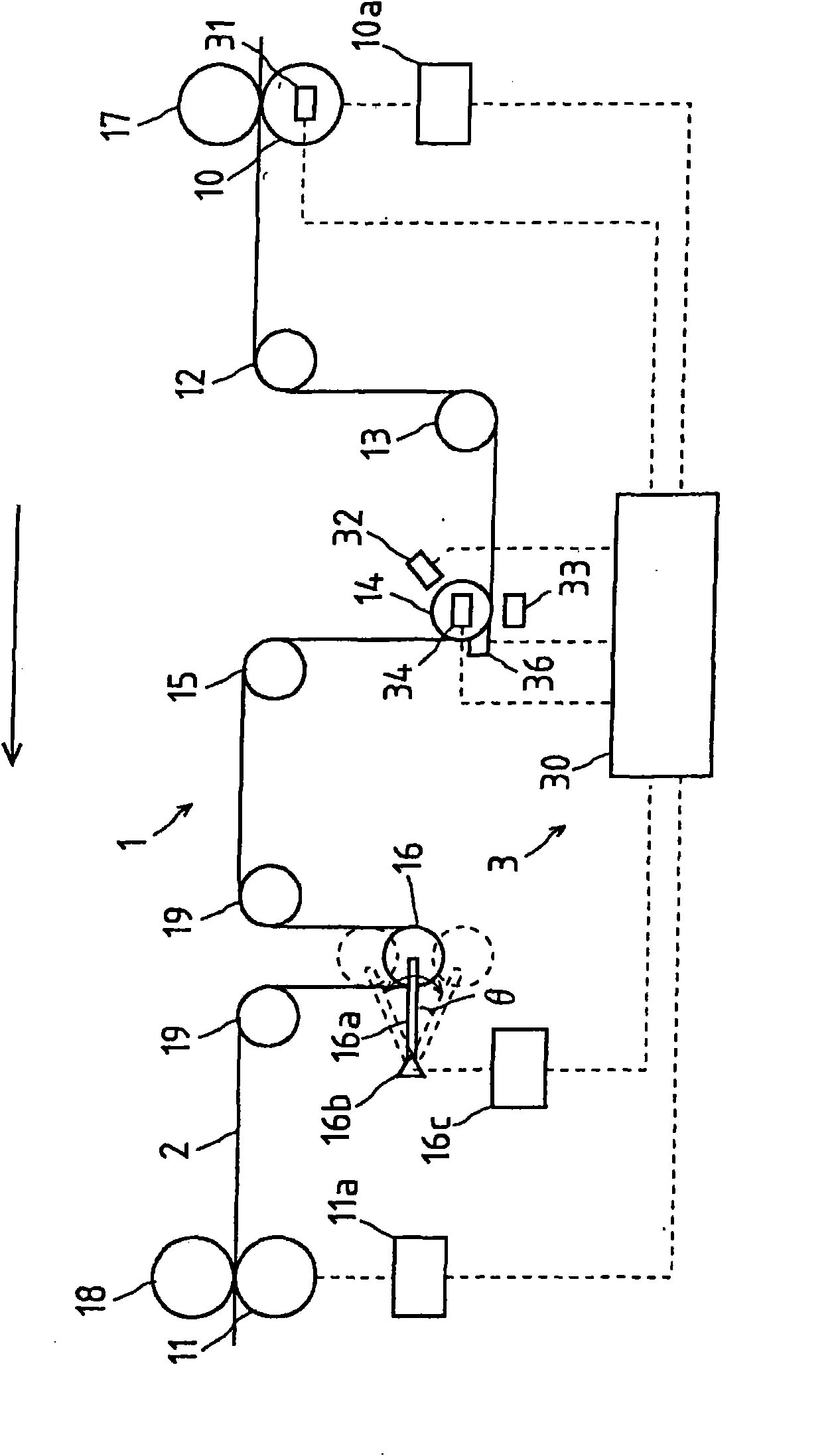

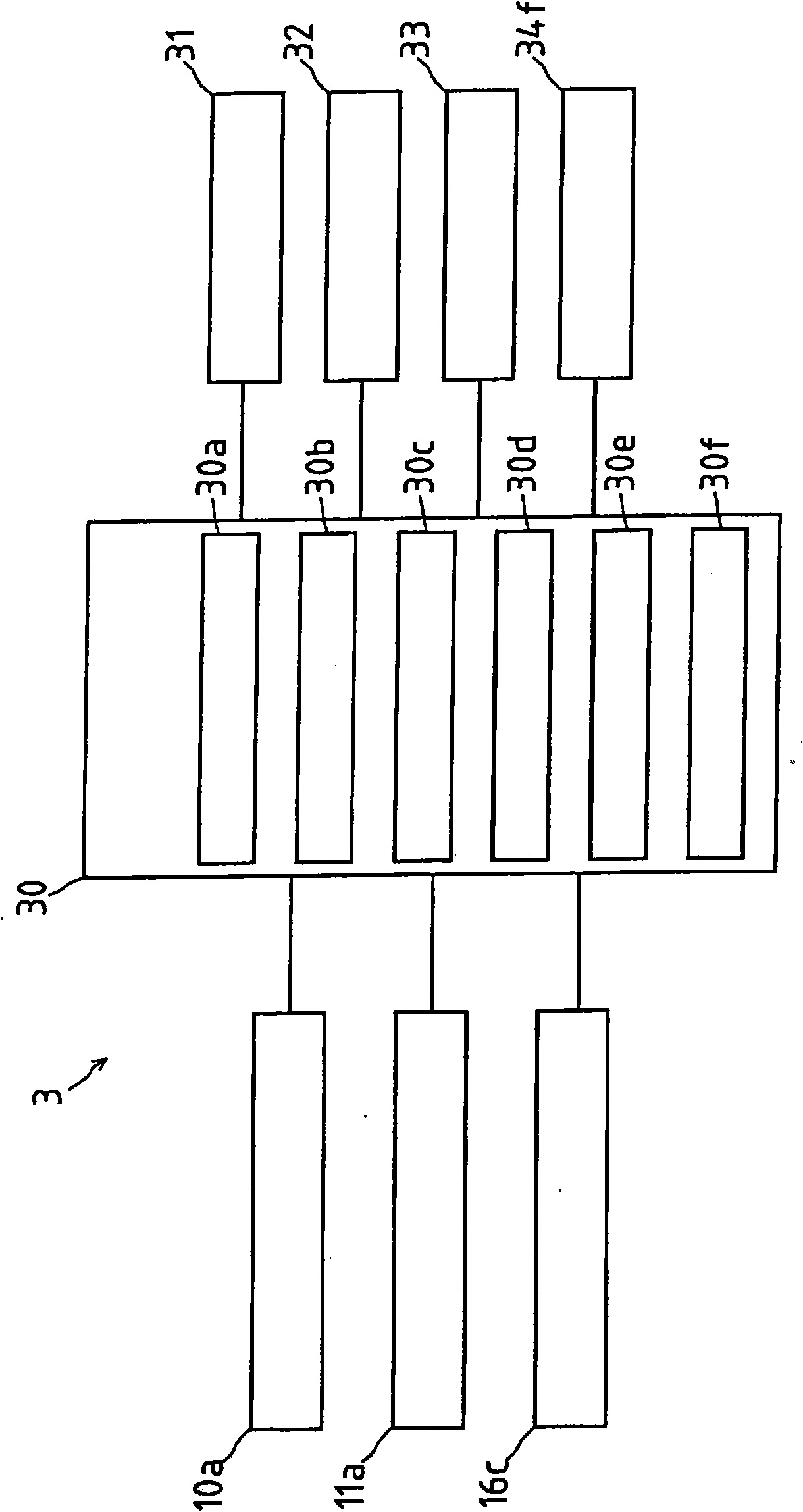

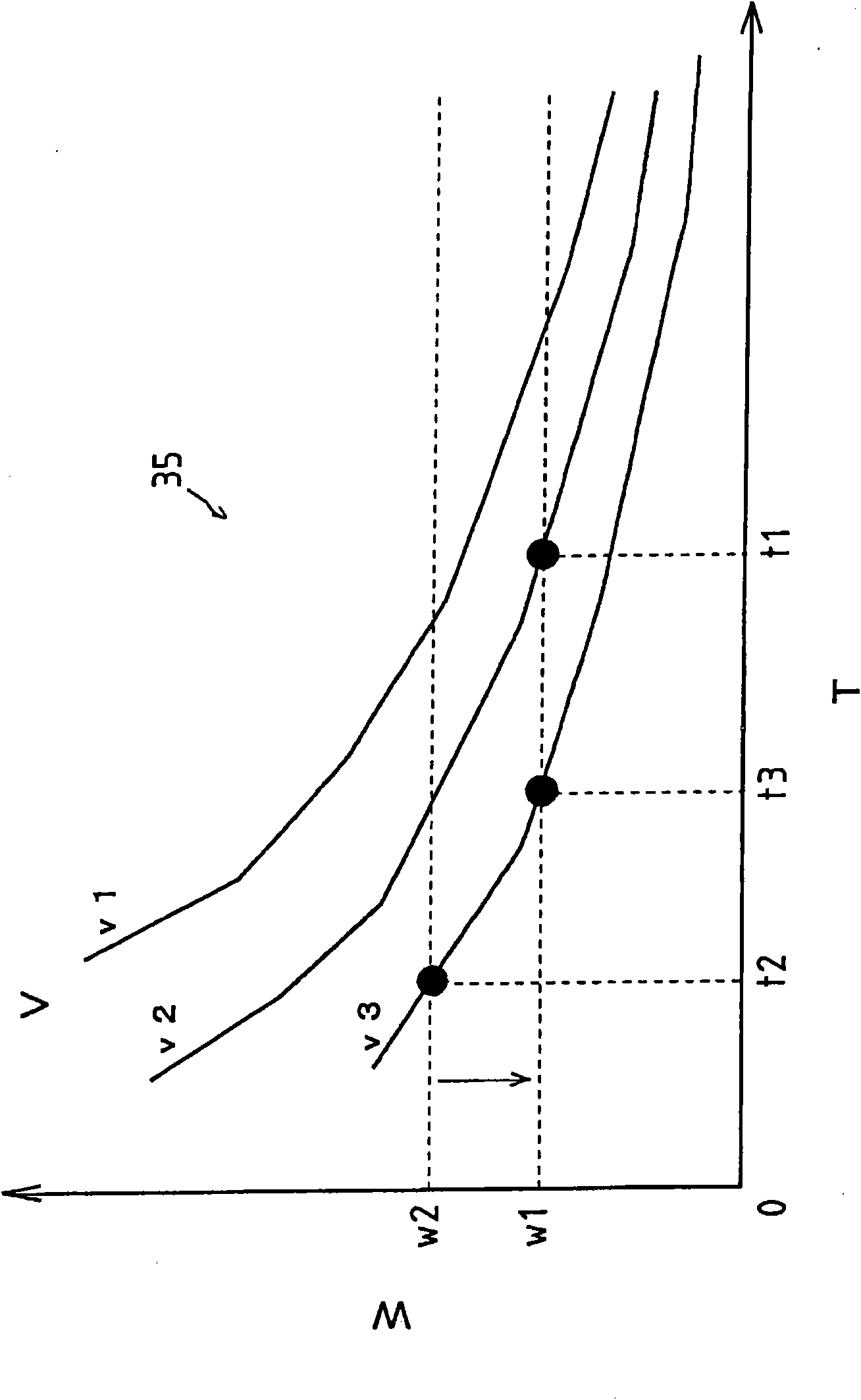

[0027] First, the overall configuration of the conveying line 1 for the web 2 will be described below.

[0028] like figure 1 As shown, the conveying line 1 of this embodiment is provided with a reference roller 10 on the upstream side of the conveying direction of the thin strip 1, and a feed roller 11 is arranged on the downstream side of the conveying direction of the thin strip 2, and from the reference roller 10 to the downstream side (Feed Roller 11) Guide rollers 12·13·14·15, dancer rollers 16, etc. are arranged in this order, and the web 2 is conveyed by being wound by these guide rollers 12 etc. at a predetermined contact angle.

[0029] Nip rollers 17·18 are provided on the reference roller 10 and the feed roller 11, respectively. The pinch rollers 17·18 are configured to be in pressure contact with the reference roller 10 and the feed roller 11 respectively by means of an unshown cylinder or the like, so as to prevent the thin strip 2 from being placed on the refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com