Water drainage structure for electric connection box

一种电连接箱、结构体的技术,应用在电路或流体管路、电气元件、电气设备外壳/柜子/抽屉等方向,能够解决不能充分防止浸水、模具结构复杂、绝缘不良等问题,达到结构简单、缓和压力、防止浸水的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

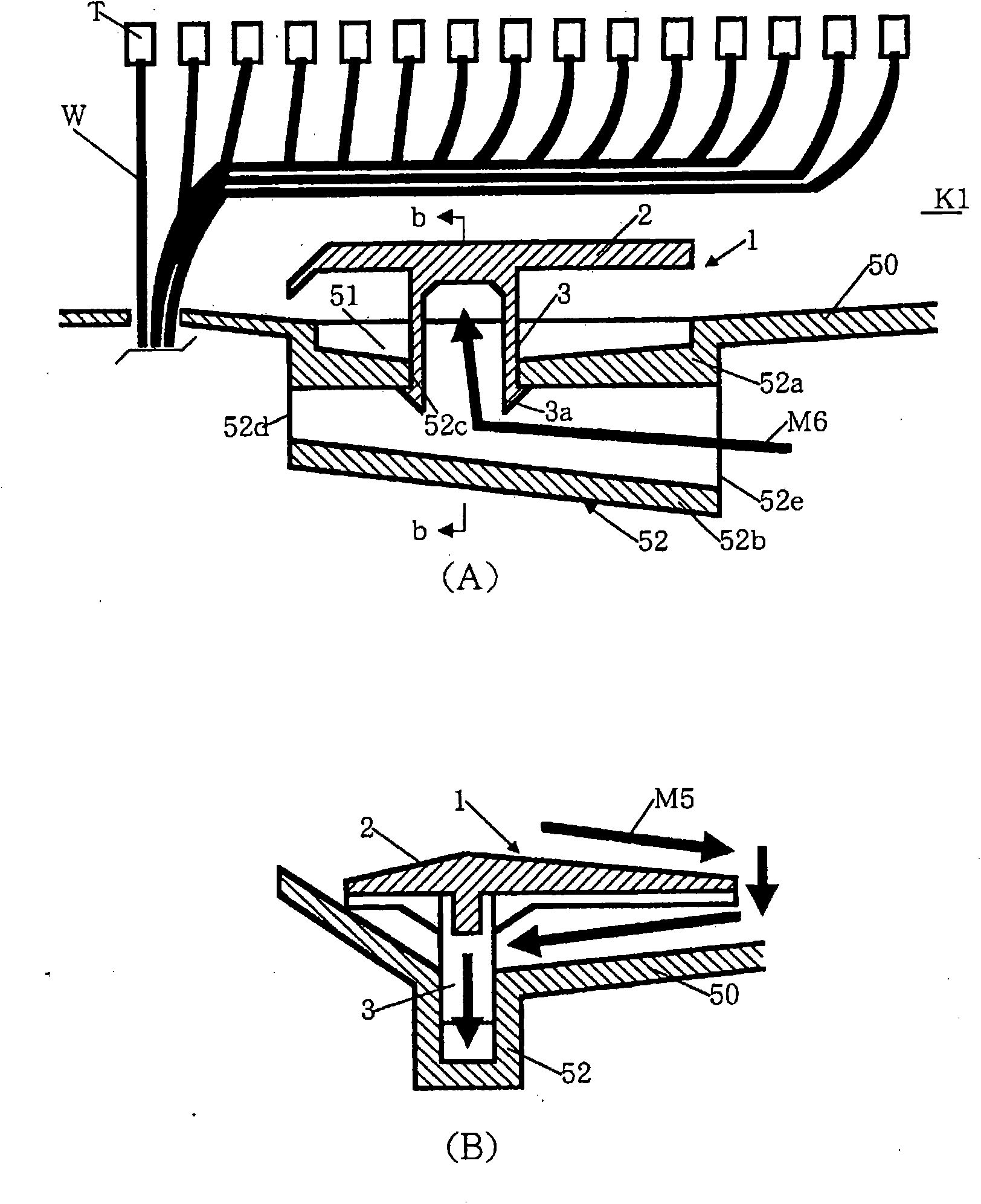

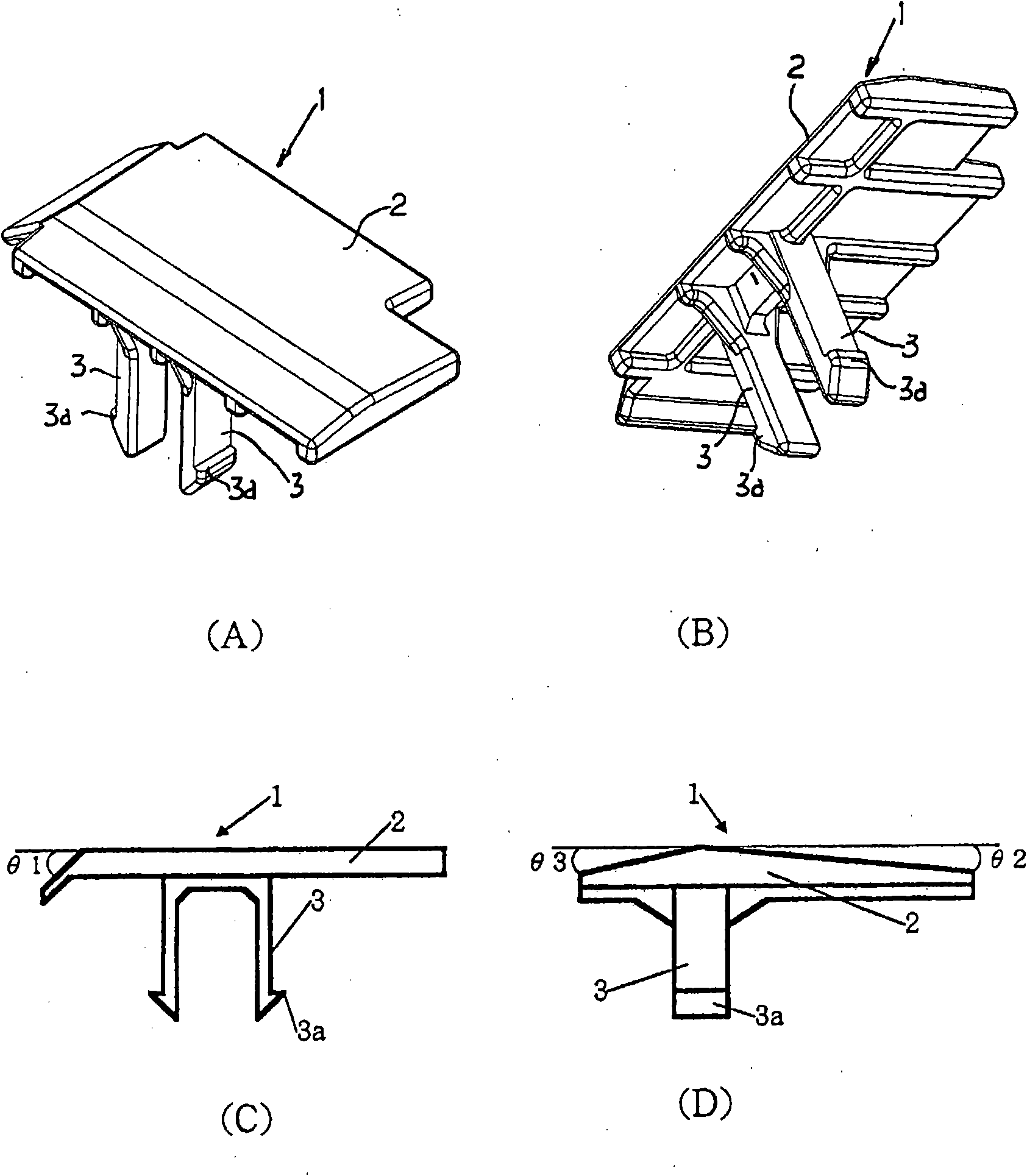

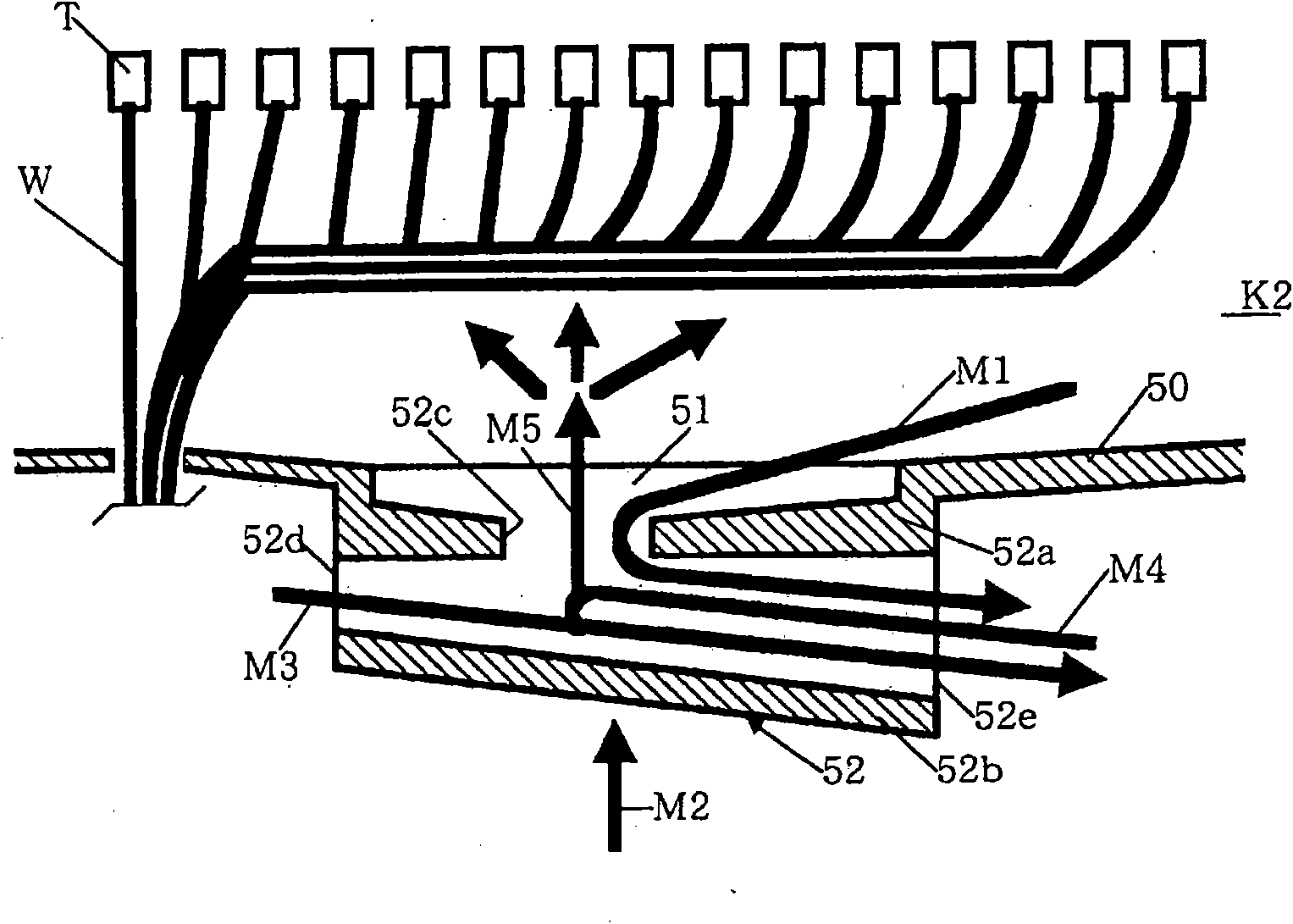

[0044] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 (A) is a cross-sectional view showing the drainage structure of the electrical junction box in an embodiment of the present invention, (B) is a cross-sectional view of line b-b of (A), figure 2 (A) is a perspective view showing the waterproof cover seen from above, (B) is a perspective view showing the waterproof cover seen from below, (C) is a front view showing the waterproof cover, and (D) is a side view showing the waterproof cover view.

[0045] Such as figure 1 As shown, the feature of the drainage structure K1 of the electrical connection box in the embodiment of the present invention is: the waterproof cover 1 is installed on image 3 On the drain 52 shown.

[0046] The waterproof cover 1 includes a substantially flat cover portion 2 and a pair of hook portions 3 provided on the lower portion of the cover portion 2 .

[0047] The claws 3a are formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com