Patents

Literature

35results about How to "Reduce disconnections" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

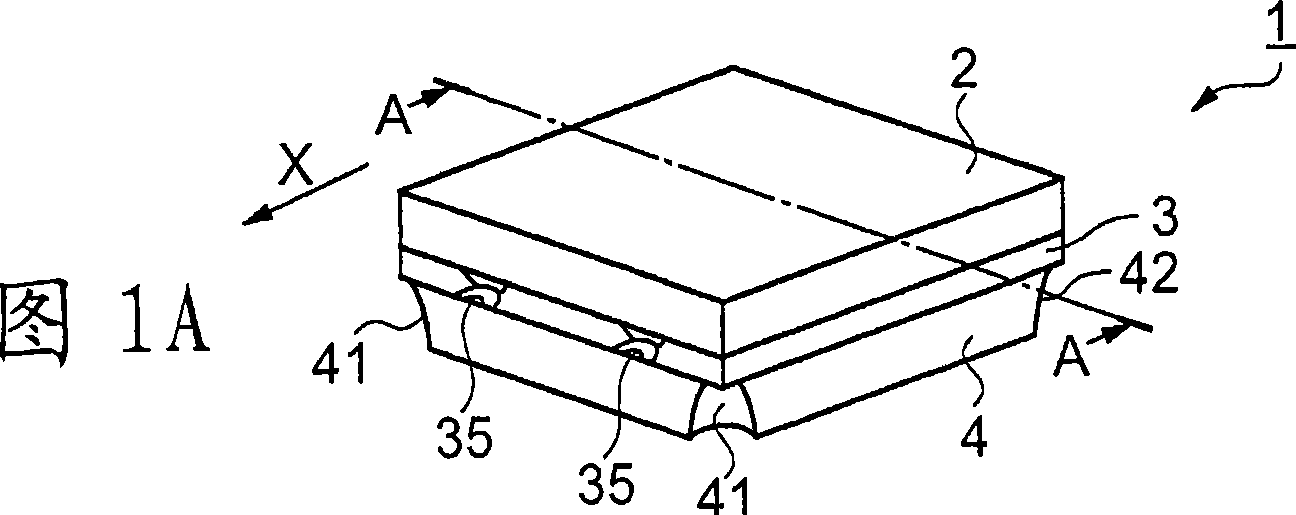

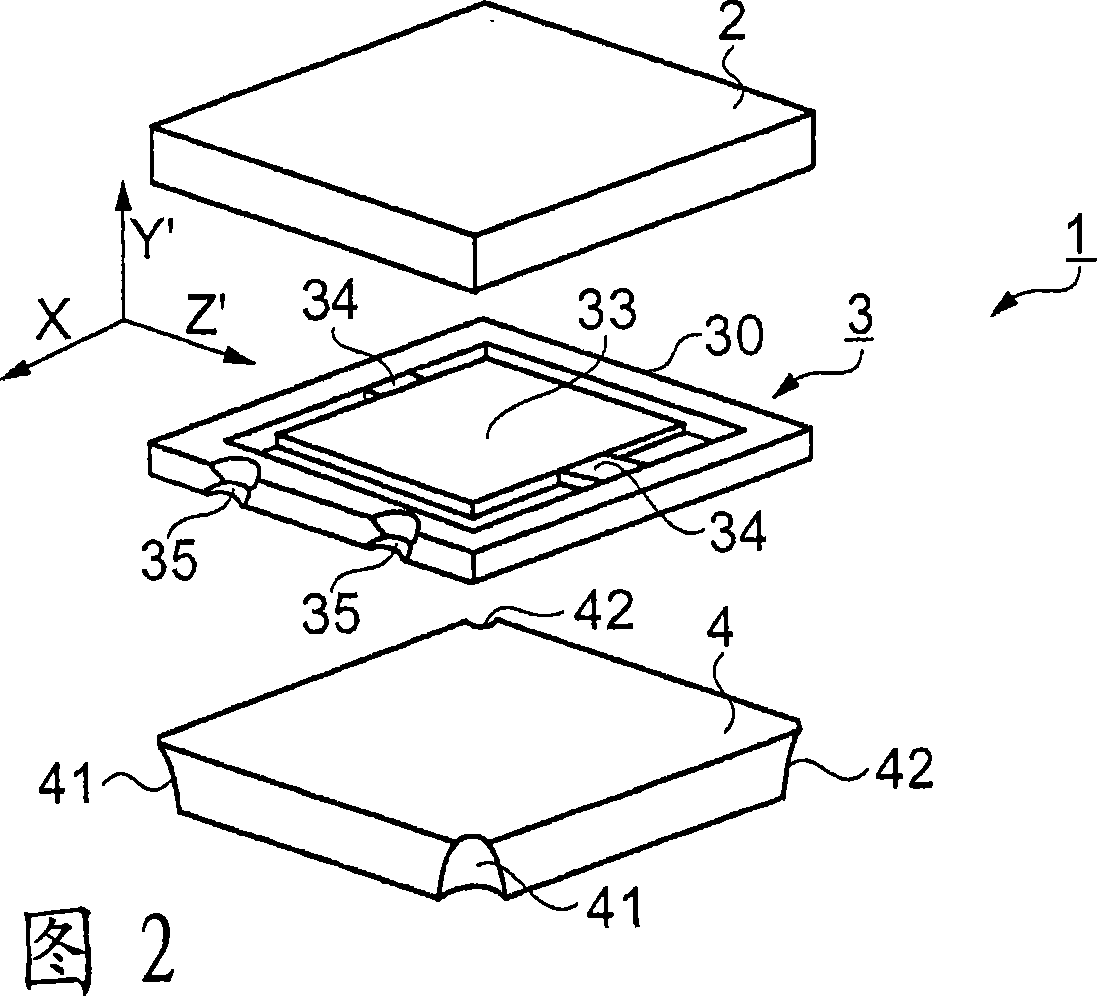

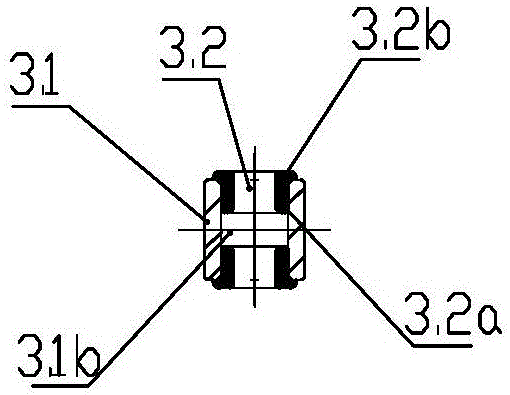

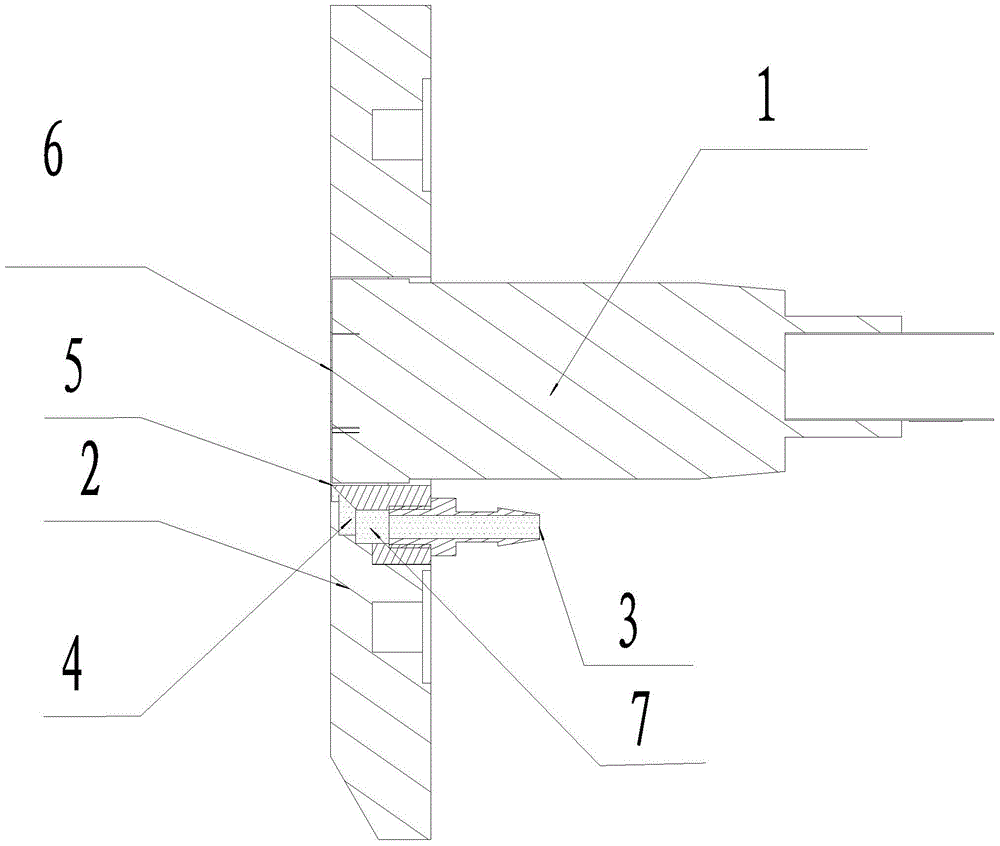

Piezoelectric resonator and method for manufacturing thereof

InactiveCN101068107AIncrease the number ofReduce disconnectionsImpedence networksPiezoelectric resonatorsAtomic physics

The invention provides a piezoelectric resonator and a method for manufacturing thereof. In order to obtain a smaller-sized piezoelectric resonator and method for manufacturing thereof, a first excitation electrode 31 formed on one surface of a vibration chip 33 is electrically connected to a third electrode 36 formed on the surface on which a second excitation electrode 32 is formed, via a recessed part 35 on the side surface of a resonator substrate 3. Therefore, the first excitation electrode 31 can be collected to the surface on which the second excitation electrode 32 is formed, and mounting on one surface can be performed. Furthermore, since the first excitation electrode 31 and a third electrode 36 are electrically connected to each other not via a through-hole but via the side surface, the resonator substrate 3 does not need any area to be penetrated and the resonator substrate 3 can be made small with respect to the vibration chip 33 of the same size. As a result, a small-sized piezoelectric vibrator can be obtained. Moreover, since the first excitation electrode 31 and the third electrode 36 are electrically connected via the recess 35, disconnection and discharge caused by contact from the outside can be reduced.

Owner:TOYO TSUSHINKI

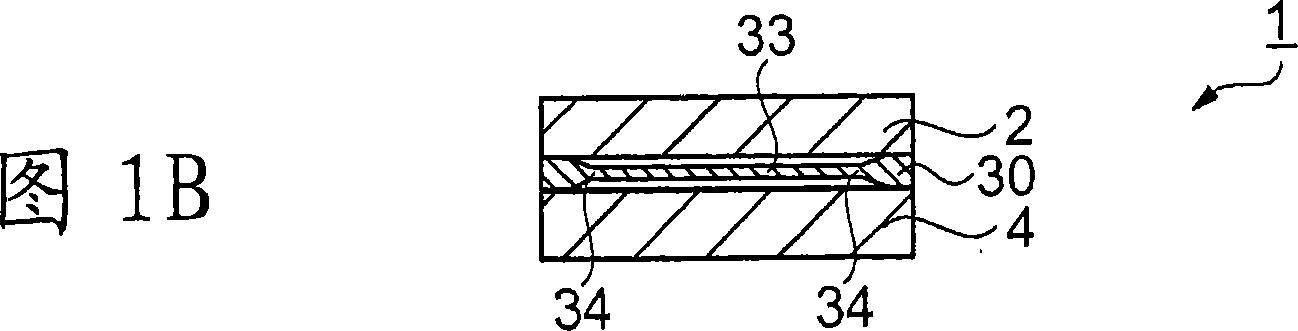

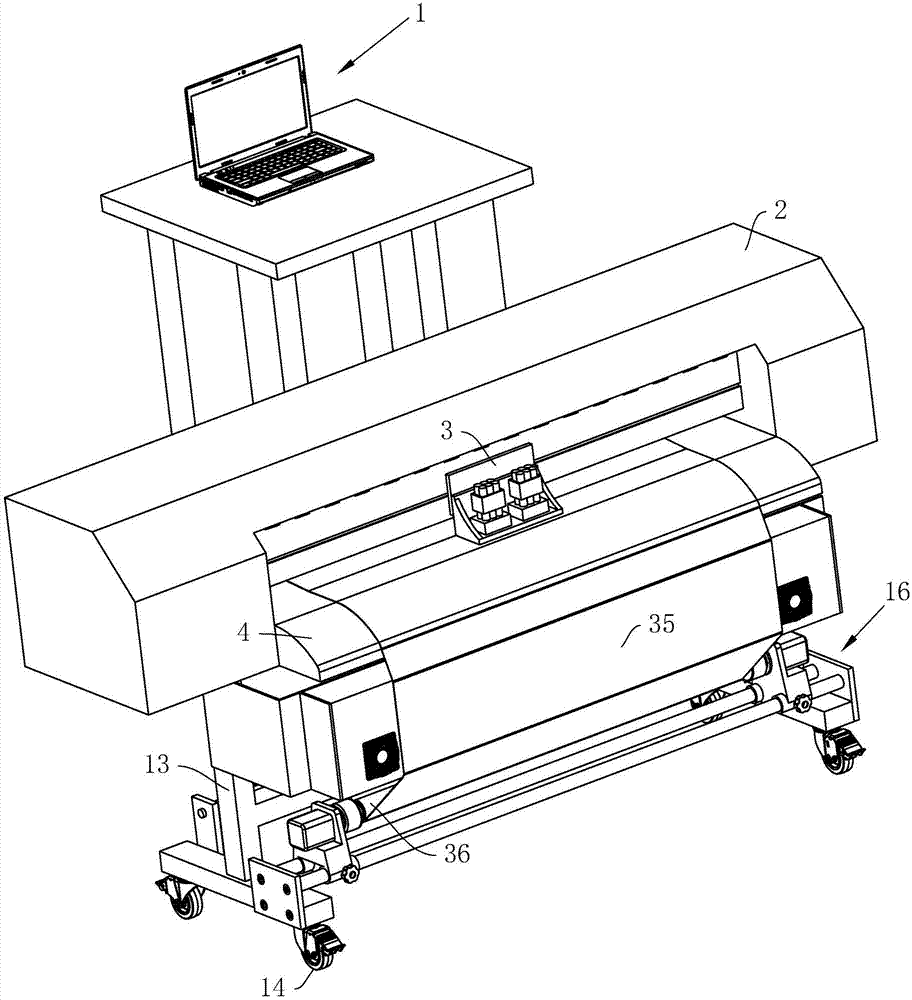

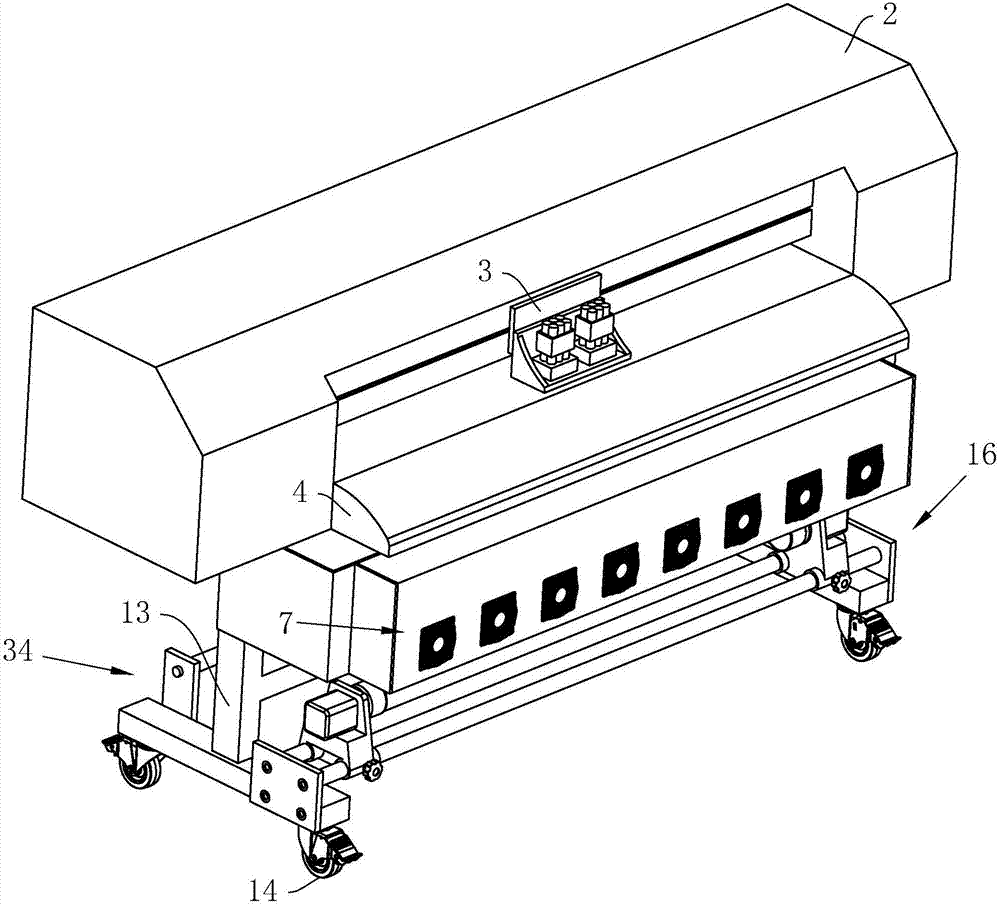

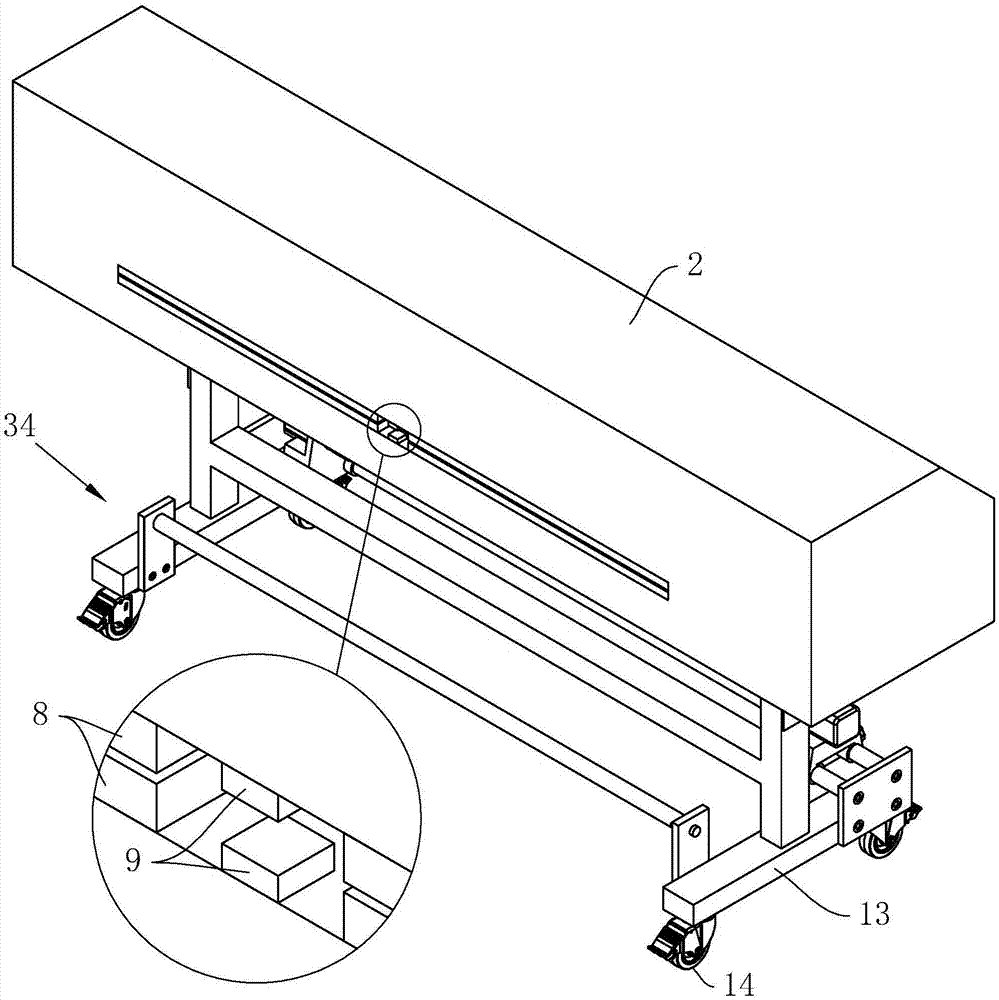

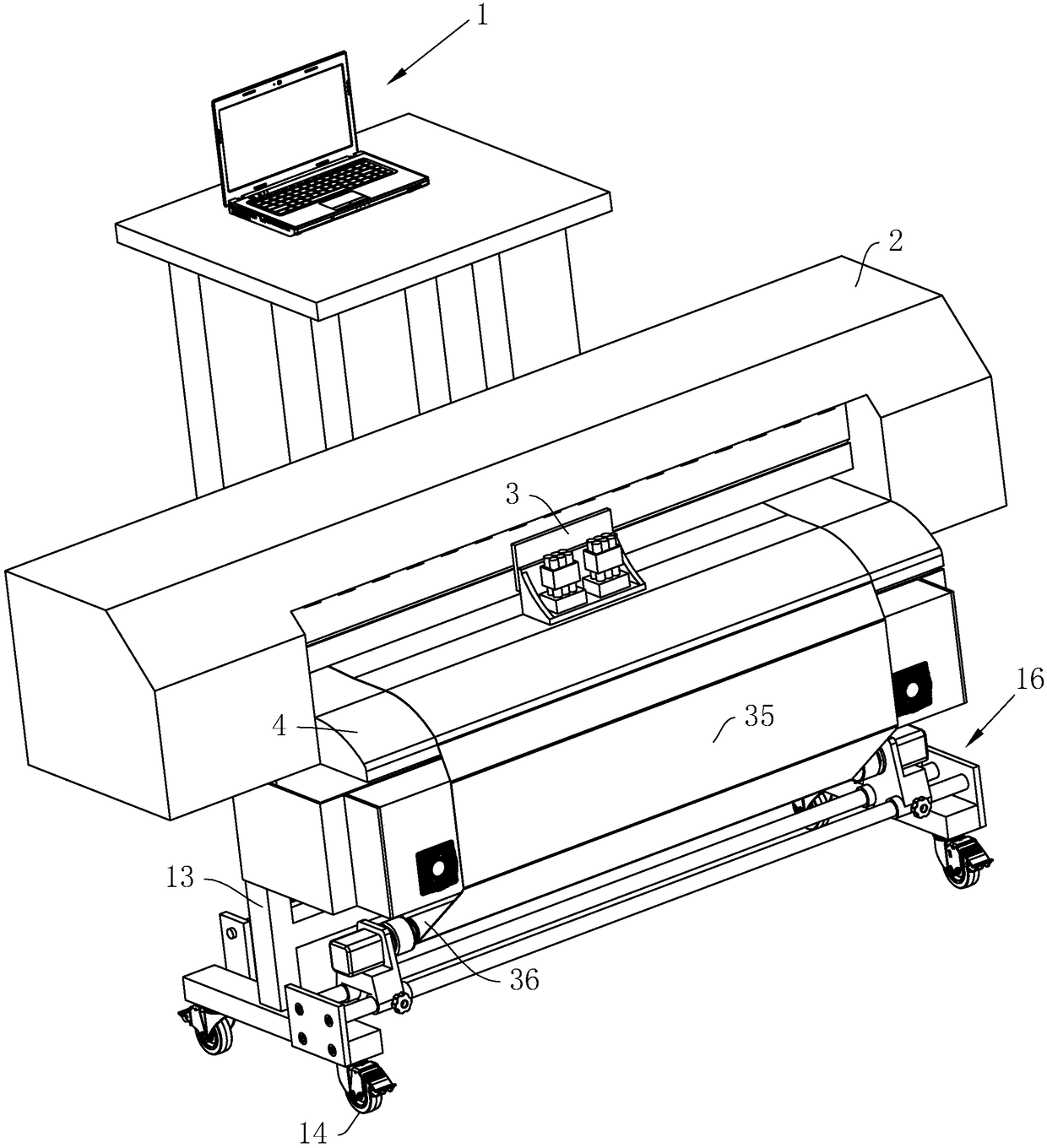

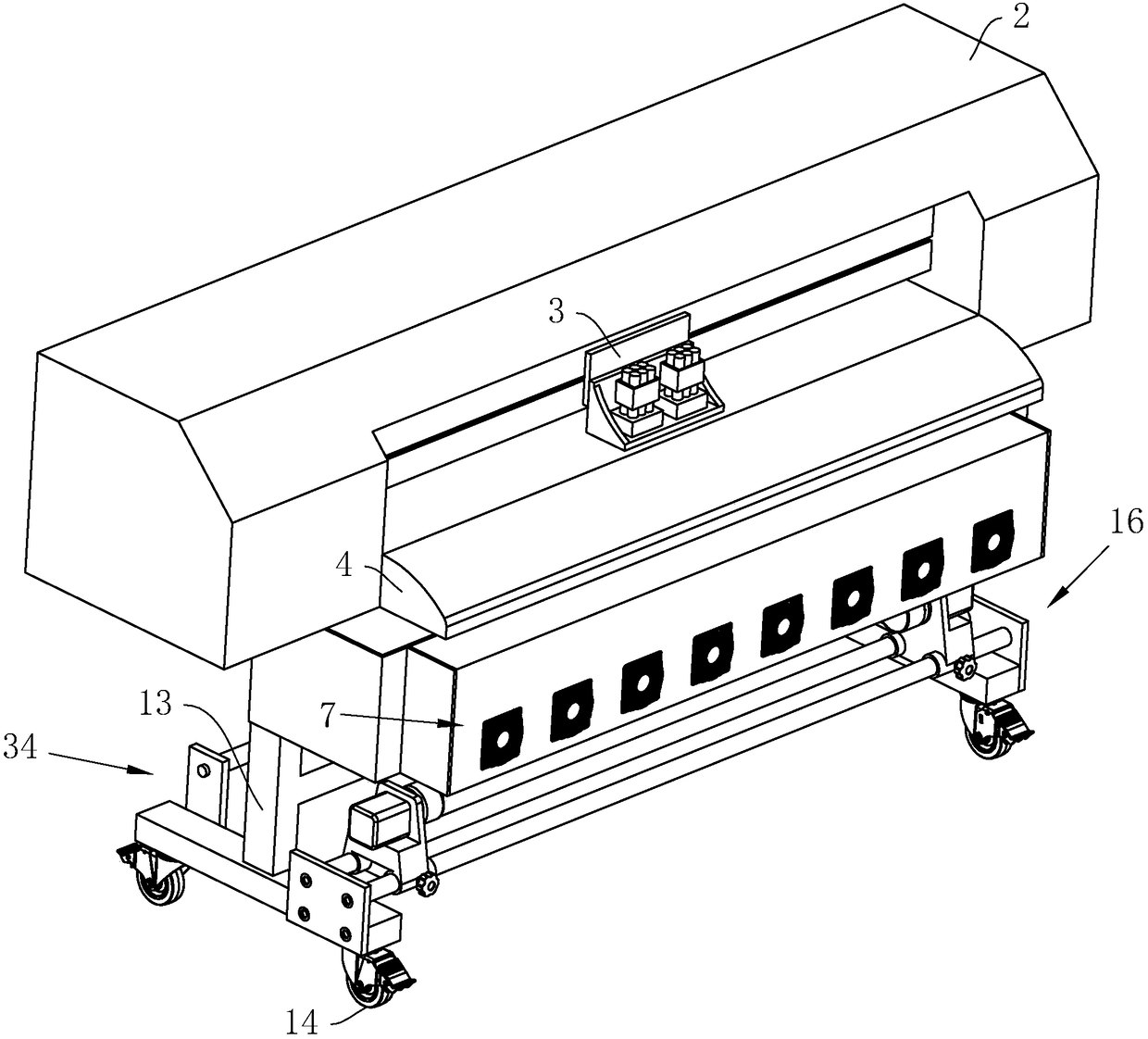

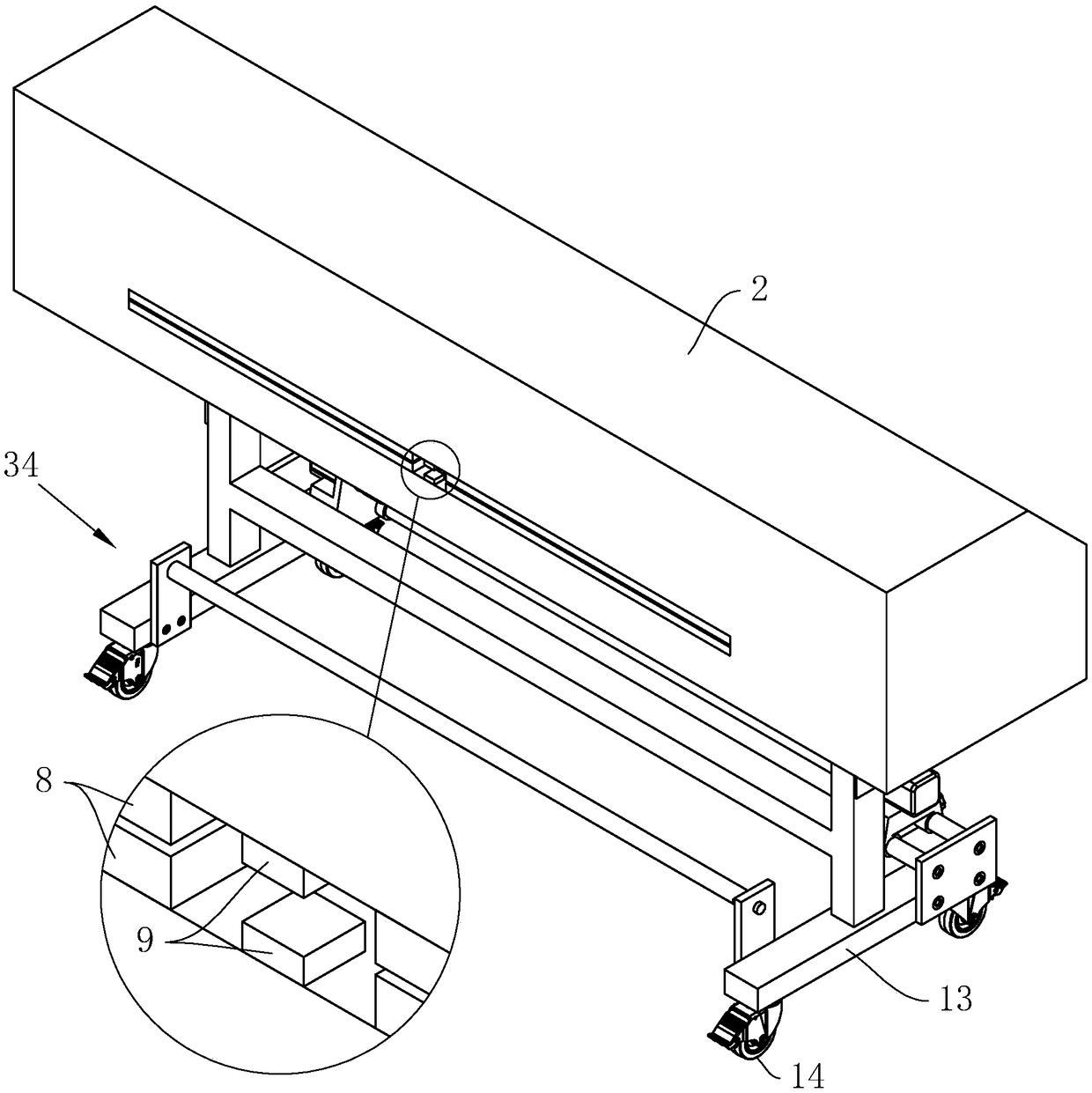

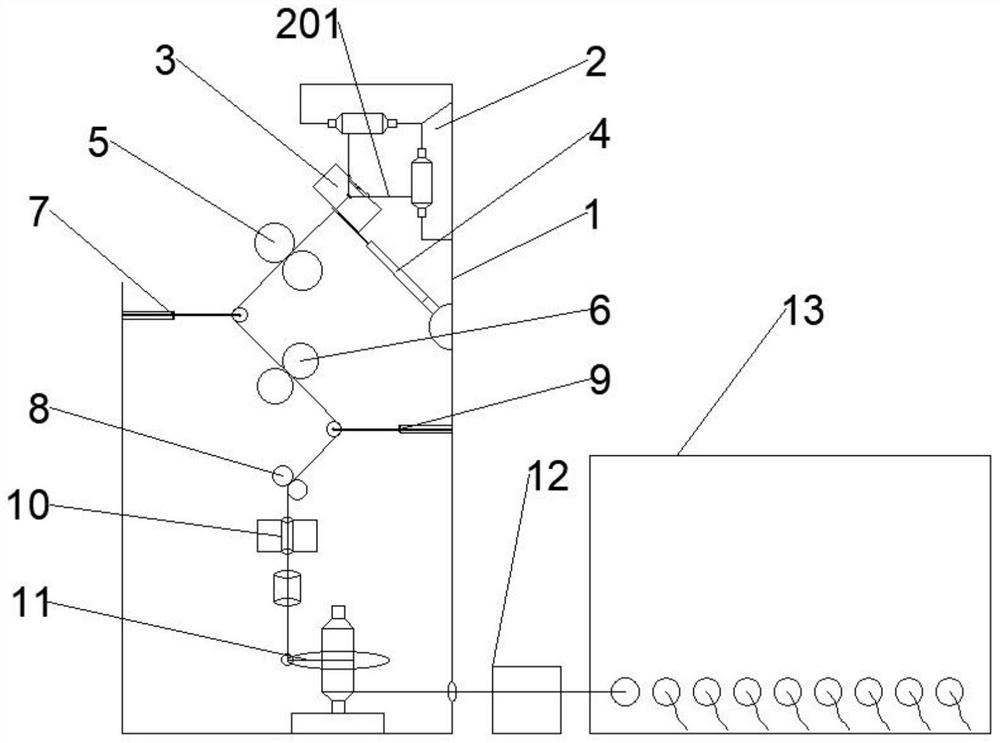

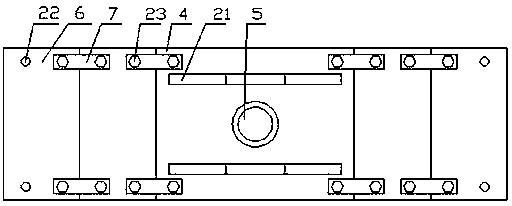

Digital printing machine

ActiveCN107284029AIncrease temperatureUniform temperatureInking apparatusOther printing apparatusComputer terminalDigital printing

The invention discloses a digital printing machine. The problems that when a digital printing machine discharges ink, due to the too low environment temperature or uneven ink temperature, the dye flow speed is not equal, and during ink discharging, wire fracturing happens to images are solved. According to the technical scheme, the digital printing machine is characterized in that an ink outlet head is further provided with a heating device connected with a master control terminal, and the printing machine body is further provided with a heating lighting device and a drying device; the printing machine body is further provided with a preheating device, the side, away from a workbench, of the printing machine is further provided with a cloth detection device, and the cloth detection device detects cloth and outputs cloth detection signals to the master control terminal; and the master control terminal controls starting of the preheating device, the heating lighting device, the heating device and the drying device. According to the digital printing machine, the ink outlet head is heated, accordingly, the temperature of the ink is increased and is more uniform, and the situation of image wire fracturing is reduced.

Owner:NANTONG JINKANGHONG TEXTILE CO LTD

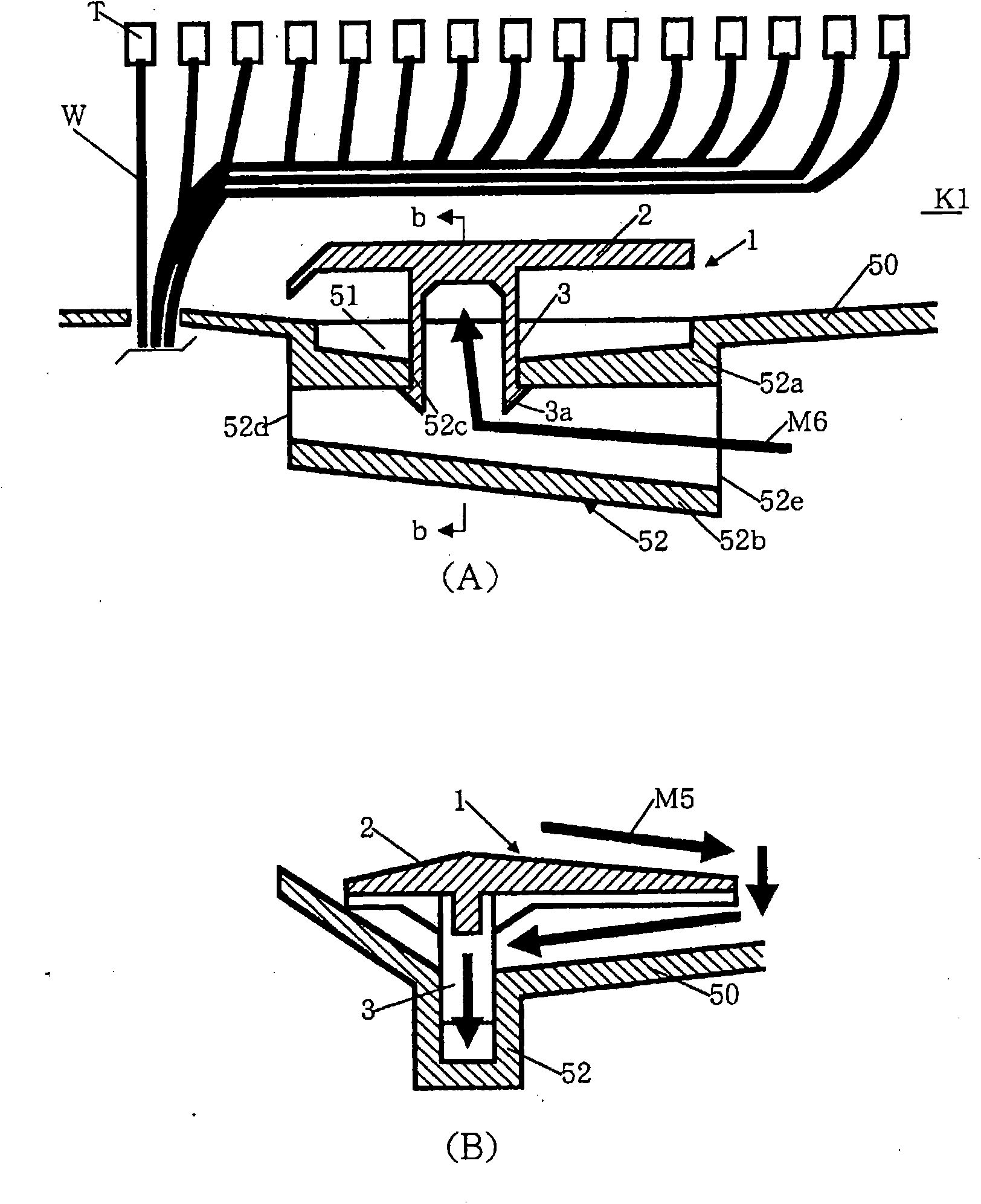

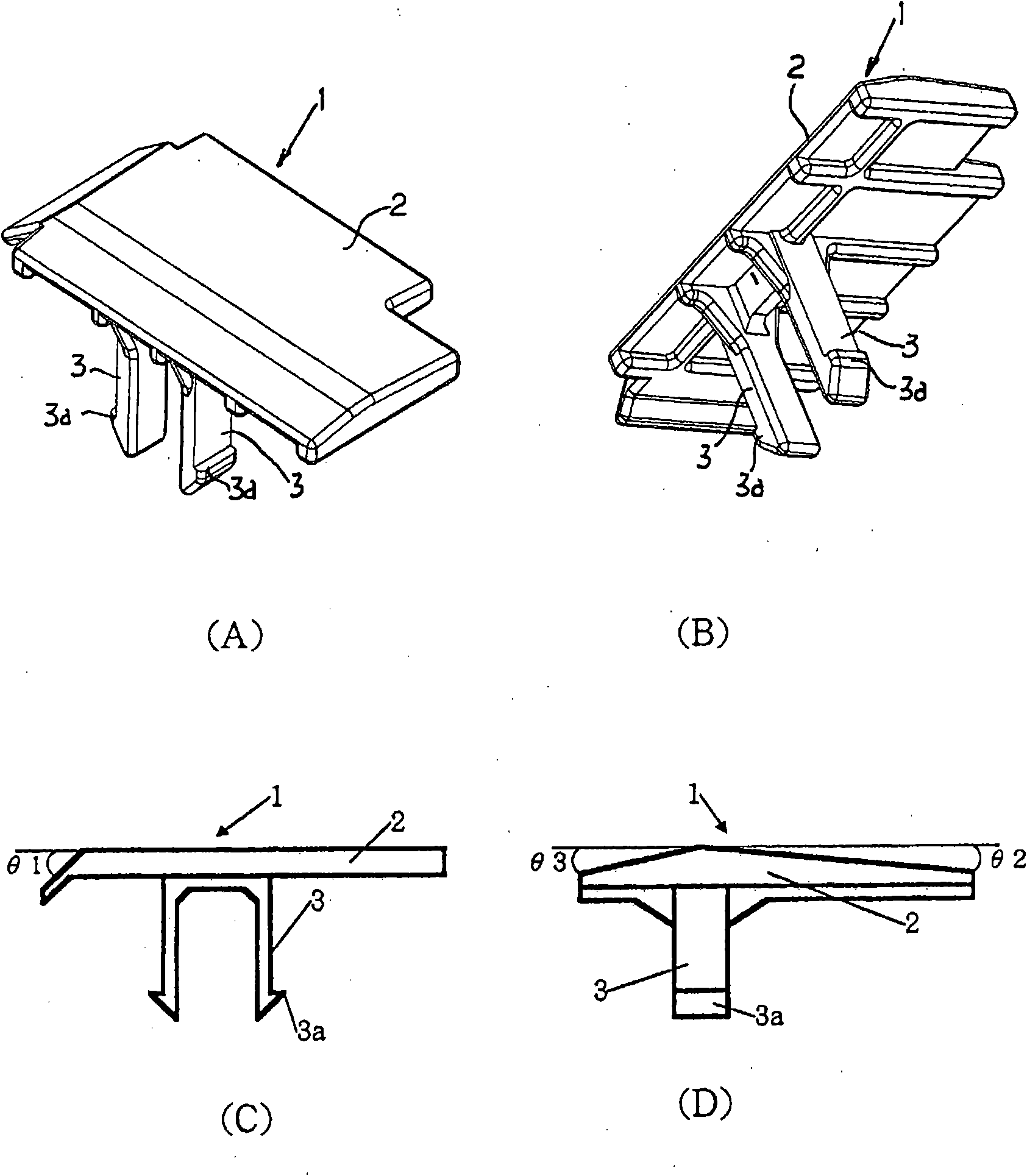

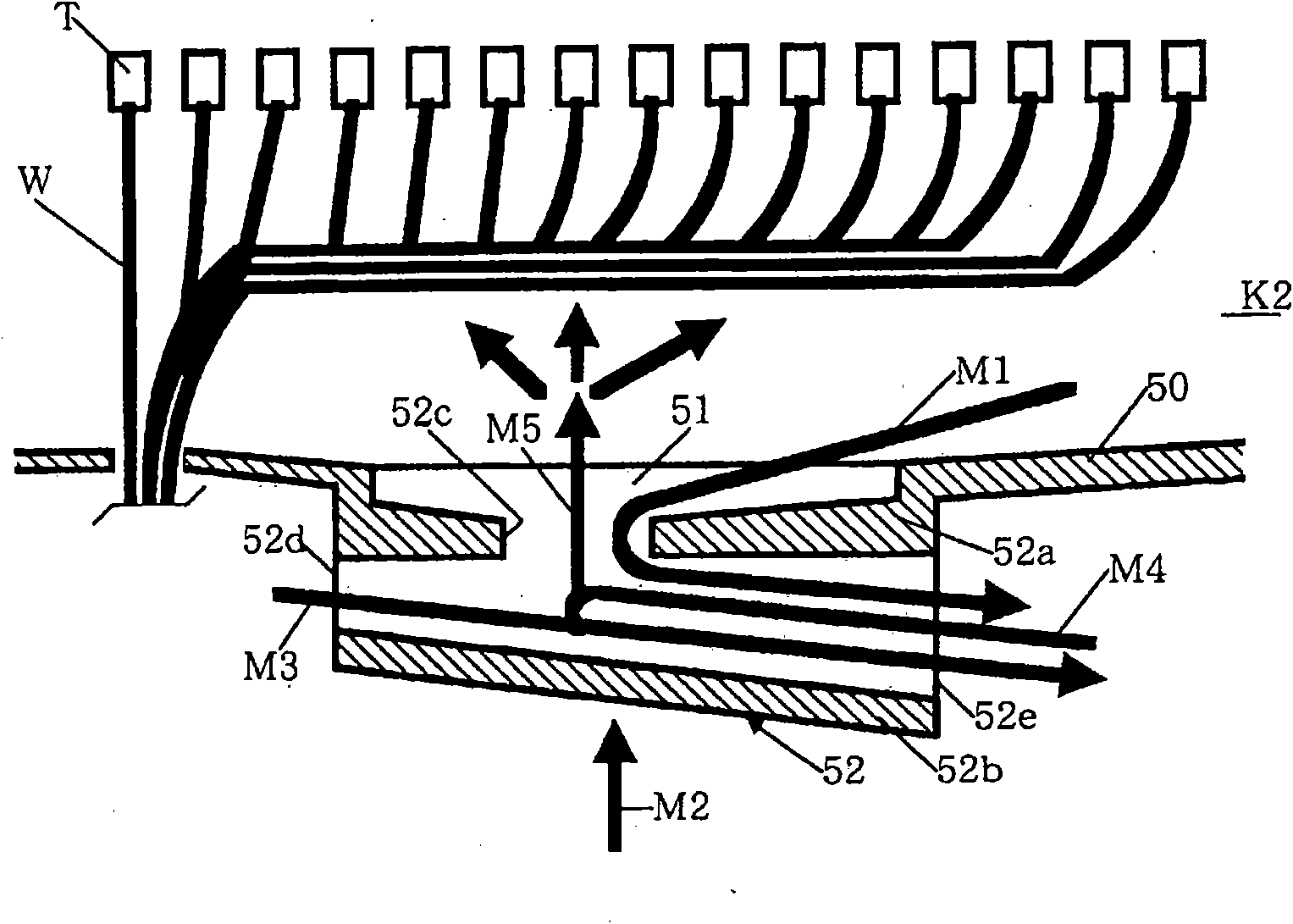

Water drainage structure for electric connection box

ActiveCN101682182APrevent sprayingPrevent floodingElectric/fluid circuitMultiple connection subassembliesElectricityEngineering

Owner:FURUKAWA ELECTRIC CO LTD +1

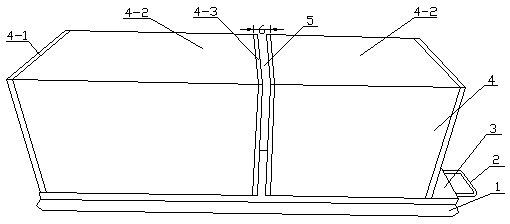

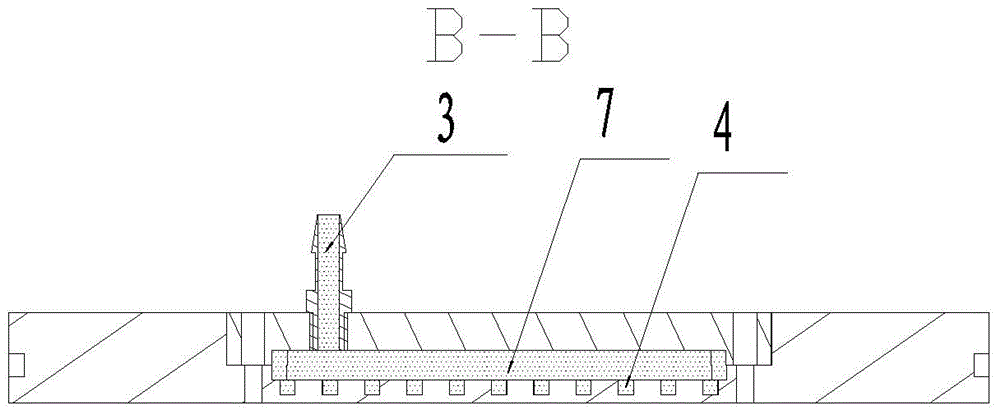

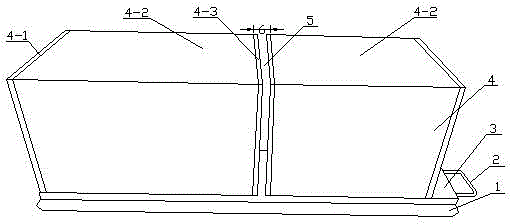

Method of cutting ingot by wire-cutting mesh

The invention discloses a method of cutting an ingot by a wire-cutting mesh, and relates to the technical field of solar ingot cutting. The method includes 1, measuring the tops and bottoms of two silicon blocks, and marking cutting positions, namely 2 to 3mm widths reserved on the tops and bottoms of the two silicon blocks, when a machine with a saw cuts, and cutting; 2, bonding a tray and glass, then bonding the two silicon blocks, reserving a gap 3 to 5mm in width between the two silicon blocks, and finishing producing the ingot; 3, marking effective cutting lengths of the silicon blocks, then loading the ingot on a fret-saw machine, weaving a mesh on a guide wheel till extending 10mm length of a non-cutting area between the two silicon blocks, cutting the mesh in the non-cutting area between the two silicon blocks, tying knots, weaving the mesh continuously till finishing, and wrapping the knots on a winding shaft. By the aid of the method, the wire-cutting mesh can be operated without pulleys, product qualified rate can be increased, and production efficiency, operation rates and capacity can be improved greatly.

Owner:HENGSHUI YINGLI NEW ENERGY

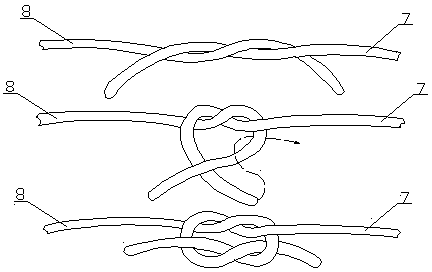

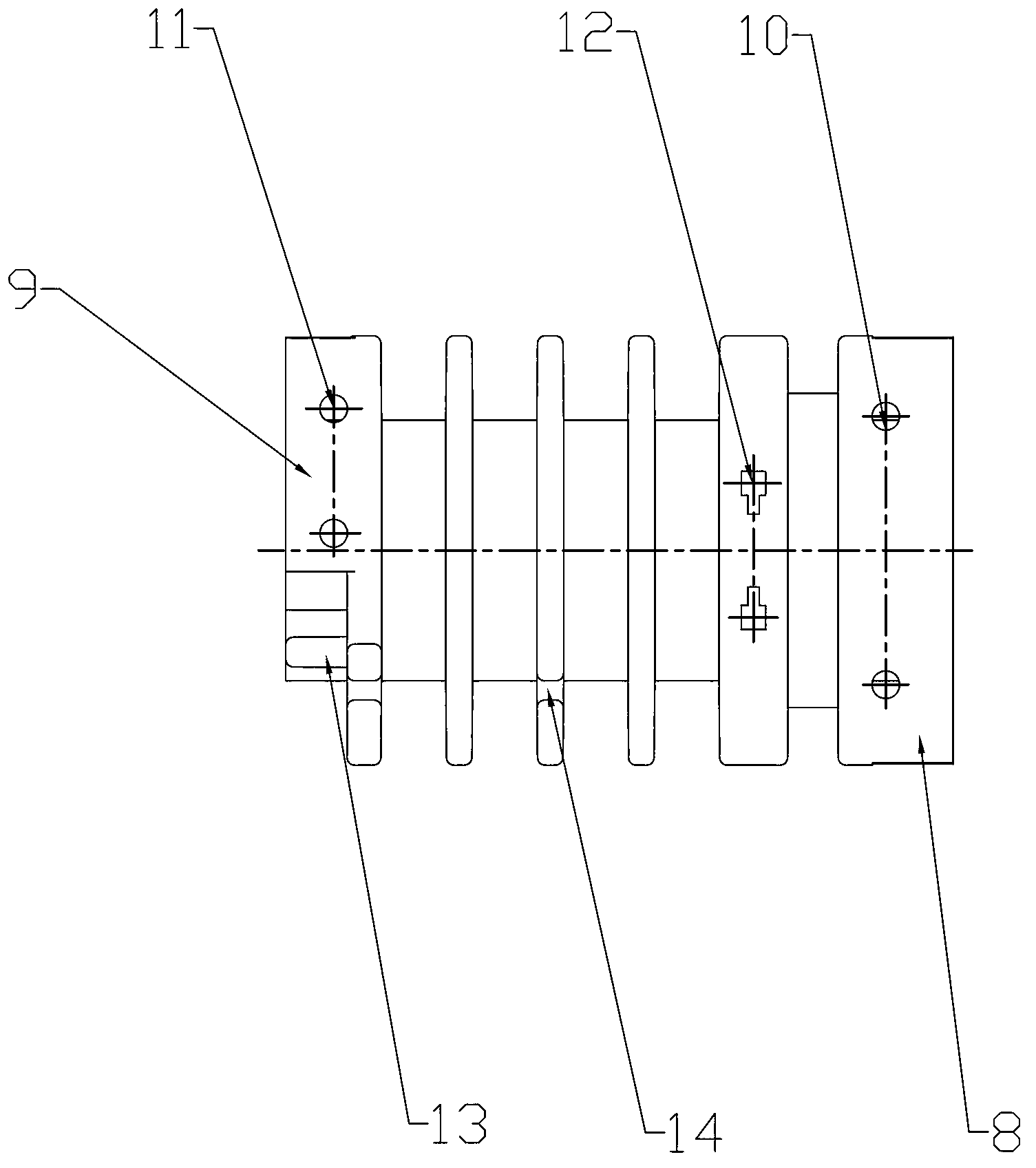

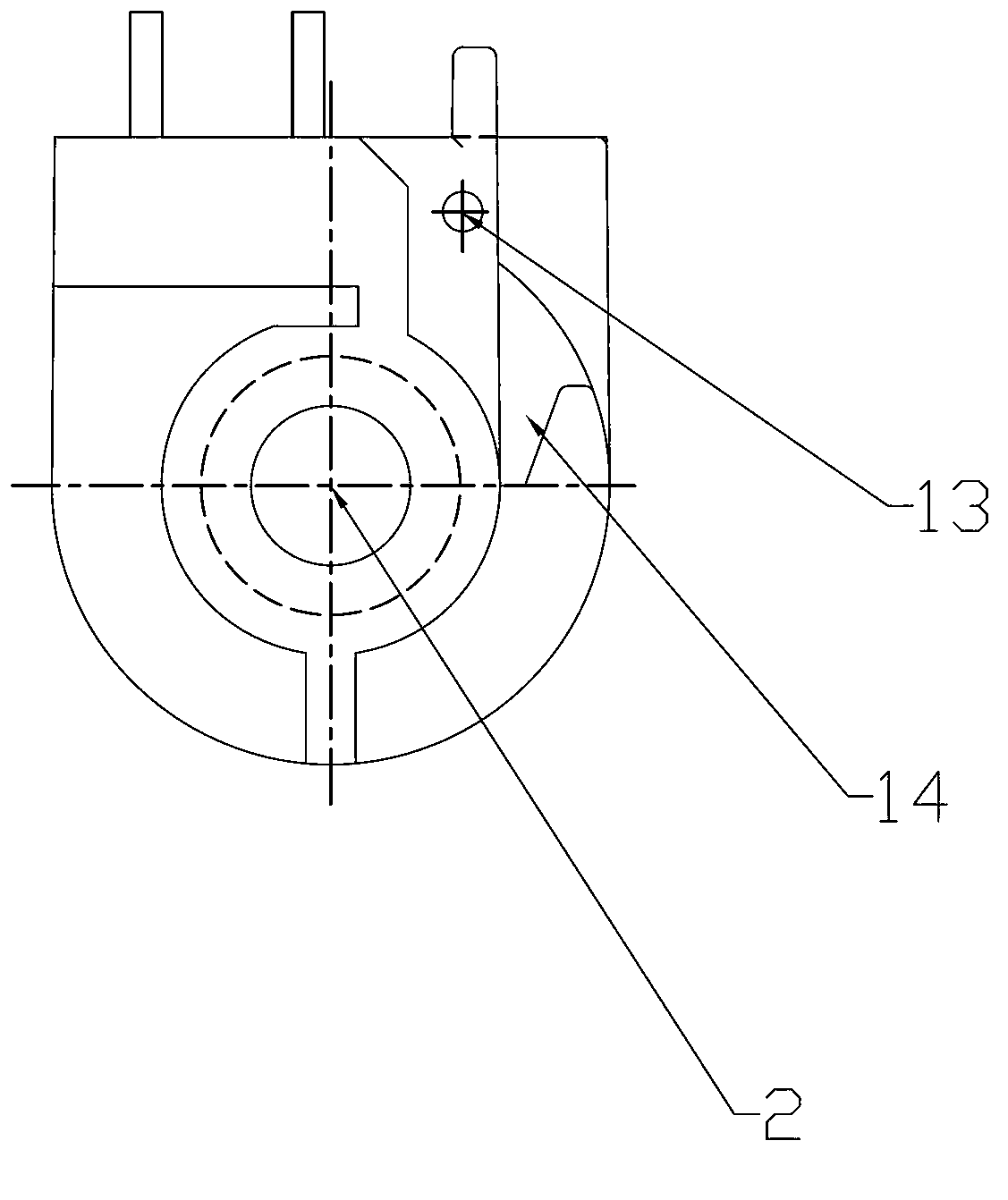

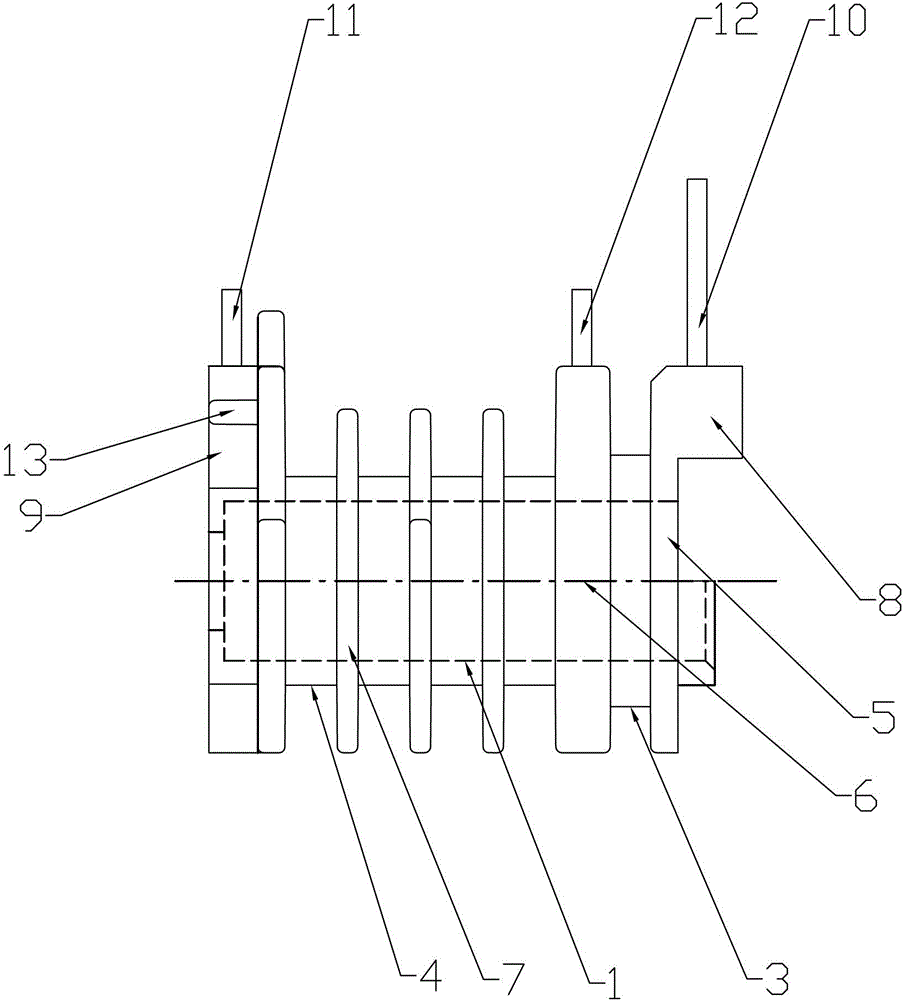

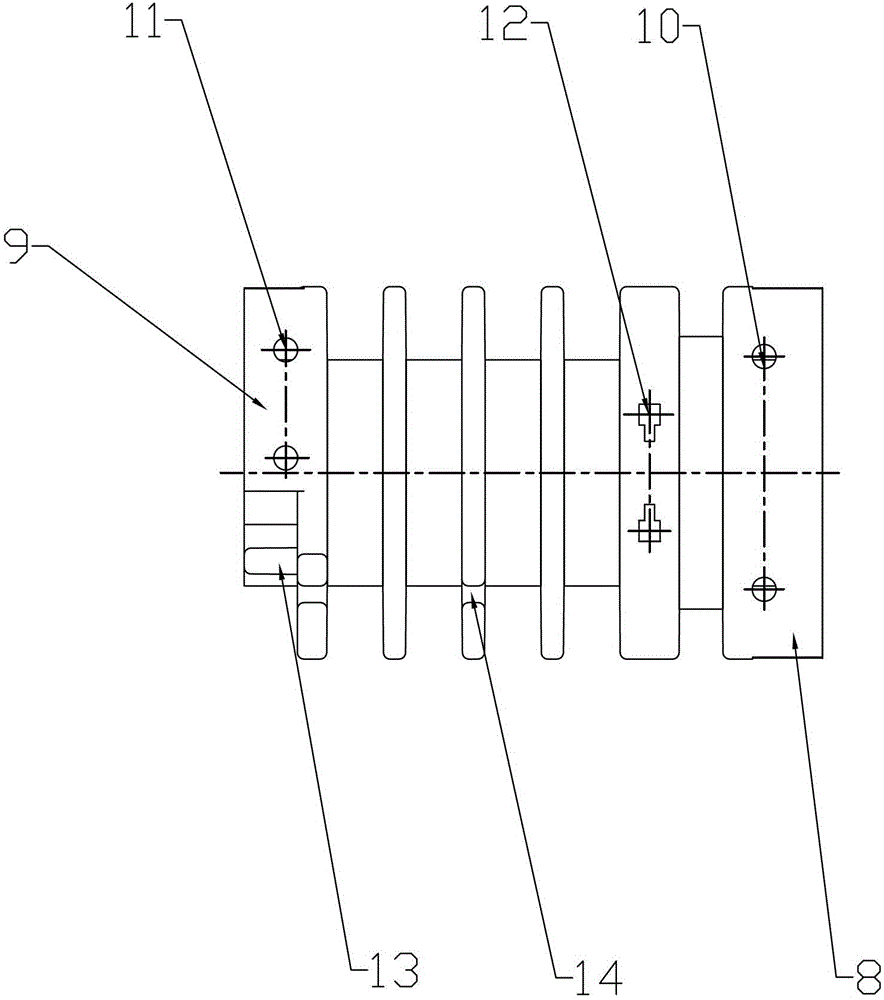

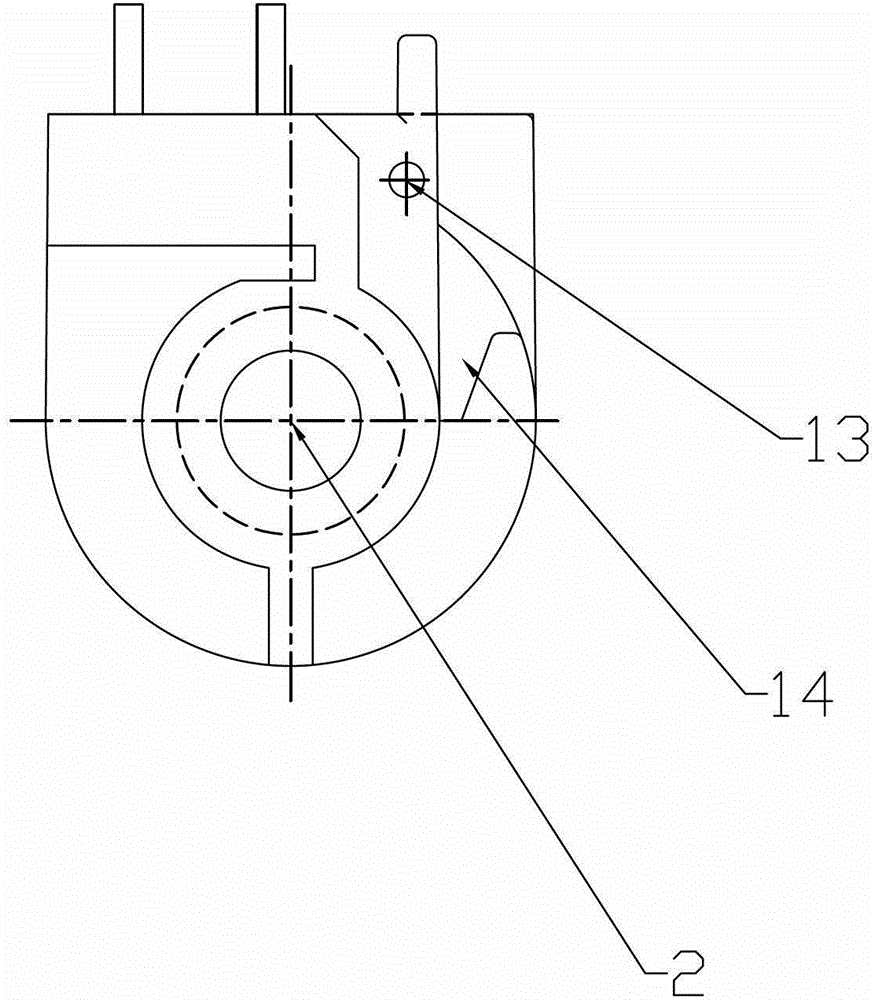

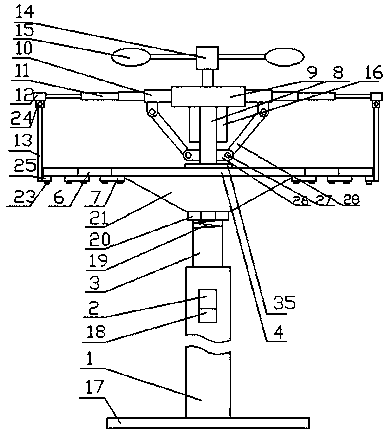

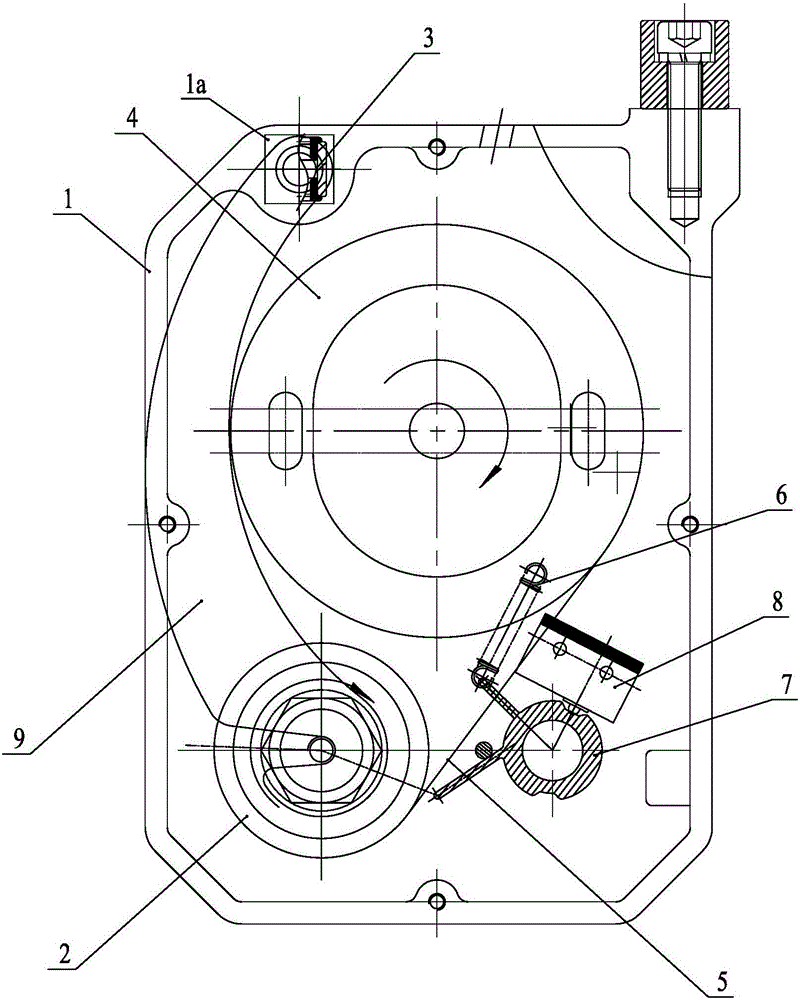

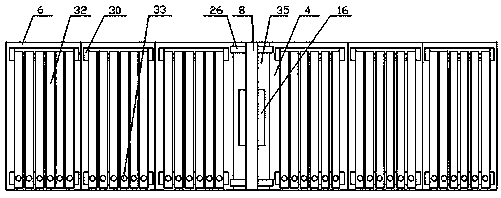

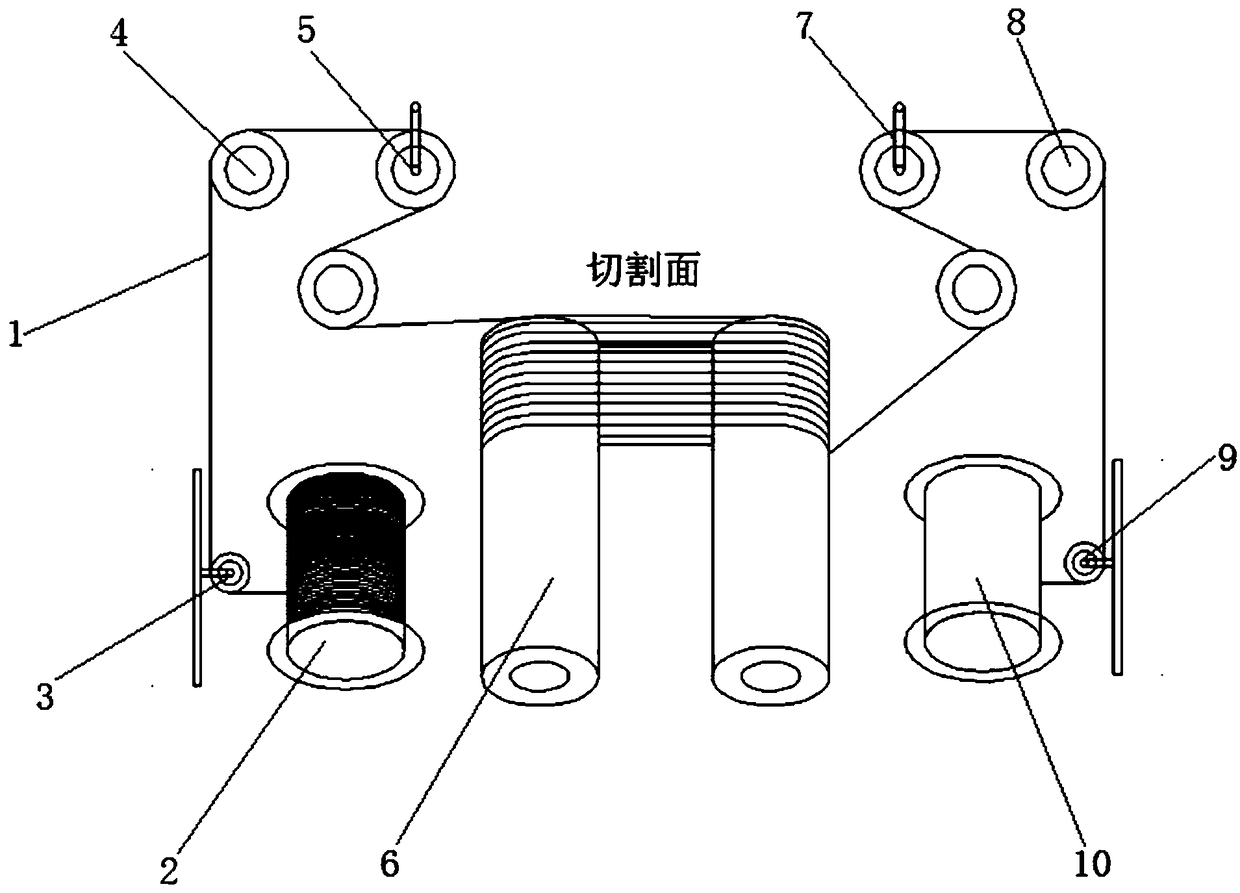

Framework of single-output ion generator

ActiveCN102938304AReduce disconnectionsCompact structureTransformers/inductances coils/windings/connectionsEngineeringStress relief

The invention relates to a framework of a single-output ion generator and belongs to the technical field of high-voltage transformers. The framework comprises an insulating framework body, and the lower ends of two first soldering tin pins penetrate out of first soldering tin pin bases. The lower ends of two second soldering tin pins penetrate out of second soldering tin pin bases. One of a plurality of secondary winding partition plates positioned on the outermost side is provided with a stress relief column. Heat dissipation gaps are arranged at the joints of the first soldering tin pins and the first soldering tin pin bases, heat dissipation gaps are arranged between the second soldering tin pins and the second soldering tin pin bases, and heat dissipation gaps are arranged between third soldering tin pins and a middle partition plate. The framework is compact and reasonable in structure, winding breaking is effectively reduced, product quality is improved, and the production cost is reduced.

Owner:WUXI TOYO ELECTRICAL APPLIANCE

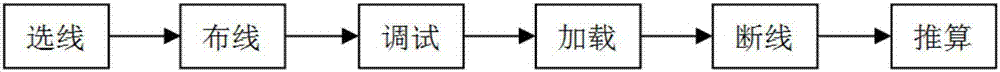

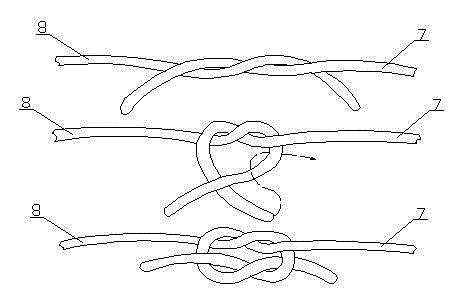

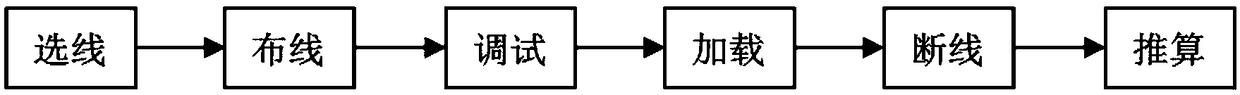

Integrally additional tension detecting method for multi-wire cutting machine

ActiveCN107214868AAvoid wastingShorten the timeWorking accessoriesFine working devicesWire cuttingDiamond

The invention discloses an integrally additional tension detecting method for a multi-wire cutting machine. The integrally additional tension detecting method for the multi-wire cutting machine comprises the following steps that diamond wires with busbar diameter of 50-80 [mu]m are arranged on the multi-wire cutting machine, and wire arrangement is conducted; and limit wire-running tension of the multi-wire cutting machine operated stably under the non-cutting state is measured, the integrally additional tension of the multi-wire cutting machine is obtained by the difference between breaking tension of the diamond wires and maximum wire-running tension. The integrally additional tension detecting method for the multi-wire cutting machine is applicable to cutting machines of different models and different manufactures are applicable, the detected machine range is wide, operation is simple and convenient, transforming for machines and extra addition of auxiliary devices are not required, detecting cost is low, and popularization is easy.

Owner:杨凌美畅新材料股份有限公司

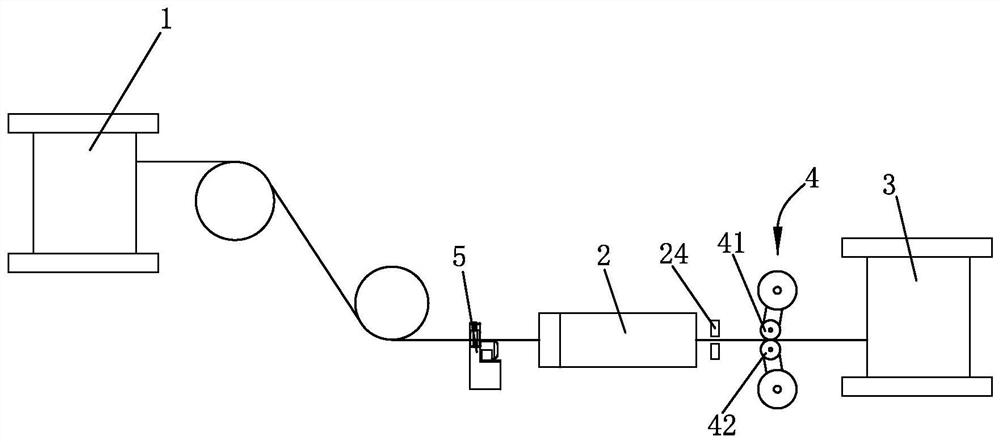

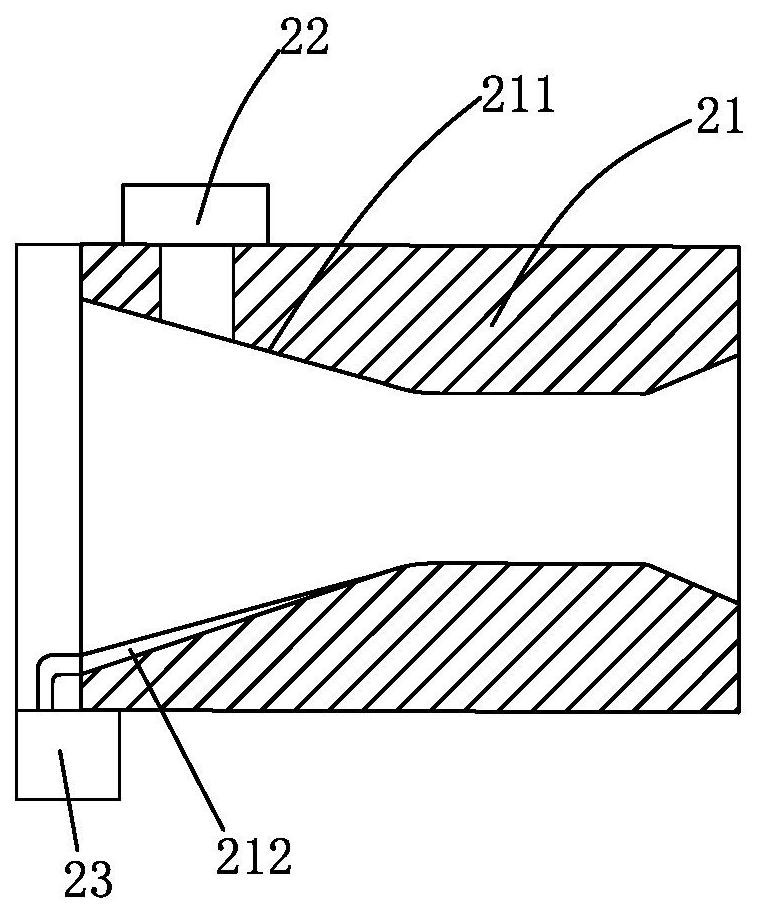

Copper wire drawing assembly

The invention relates to the field of copper wire machining equipment, in particular to a copper wire drawing assembly. The copper wire drawing assembly comprises a pay-off reel, a wire drawing die and a take-up reel which are used for sequentially passing through a drawn copper wire, wherein the wire drawing die comprises a die hole, a lubricating mechanism used for adding lubricating liquid to the copper wire is arranged at the front end of the die hole, an inlet of the die hole is a horn mouth which is gradually reduced in the entering direction of the copper wire, a drainage groove for guiding out the lubricating liquid is formed in the lower surface of the inlet of the die hole, and a liquid suction mechanism is arranged at an outlet of the drainage groove. According to the copper wire drawing assembly, on one hand, the lubricating liquid is used for achieving the lubricating effect, on the other hand, when the lubricating liquid dissolves and takes away impurities on the surfaceof the copper wire and powder scraps formed by abrasion, the liquid suction mechanism provides power to suck away impurities and powder scraps prone to precipitation in time, and the impurity and thepowder scraps are prevented from being accumulated at the inlet, so that the copper wire is kept clean and lubricated when passing through the die hole, the wire drawing quality of the copper wire isimproved, and wire breakage is reduced.

Owner:江西远桥电磁线科技协同创新有限公司

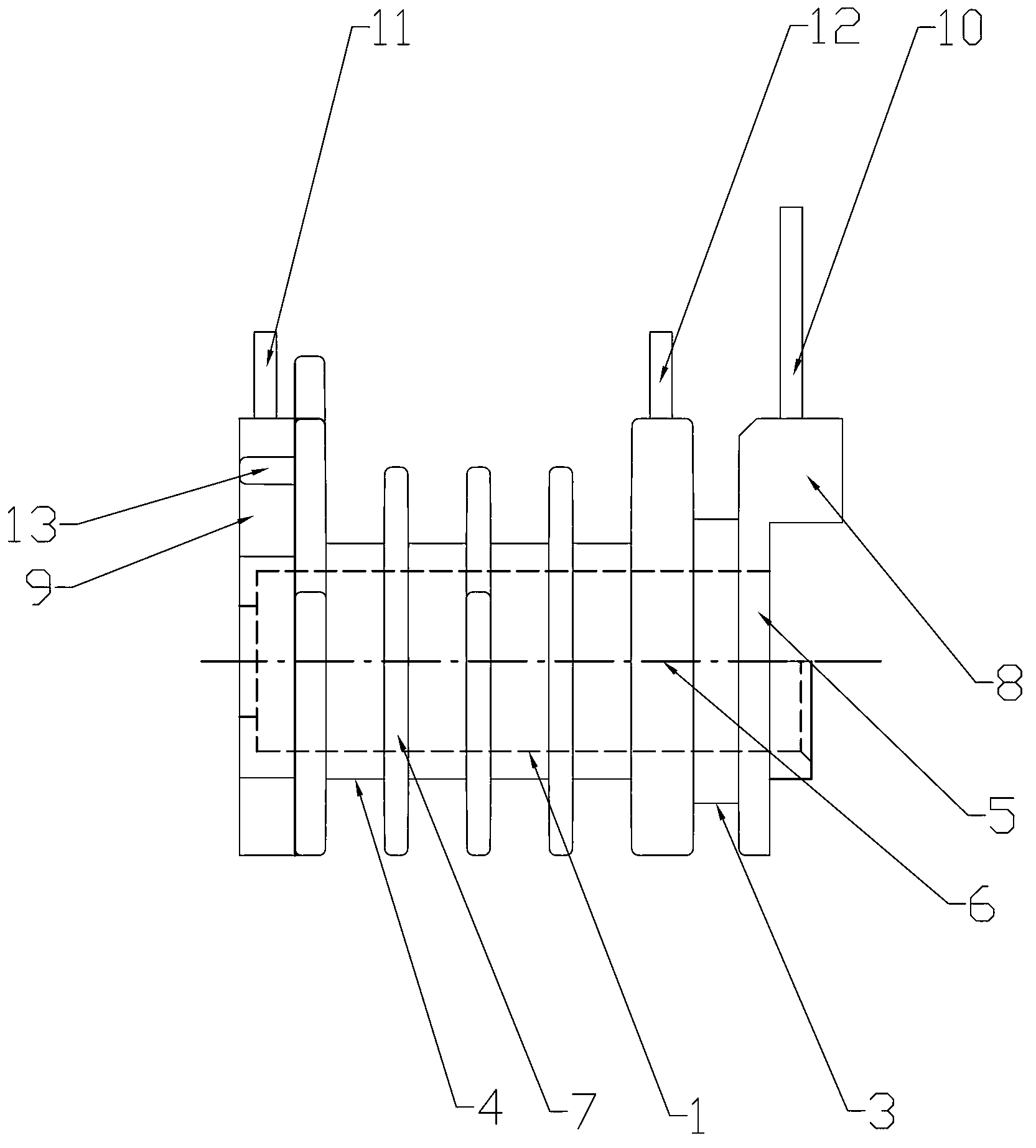

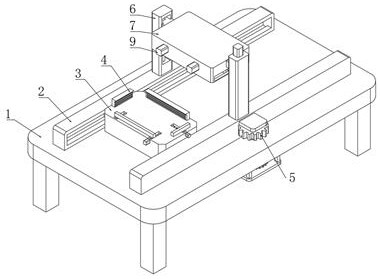

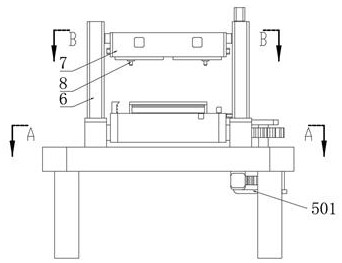

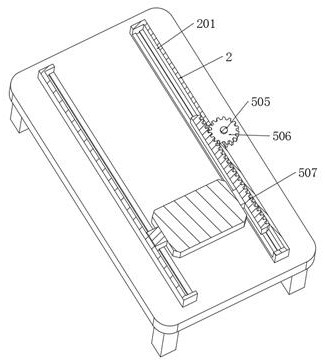

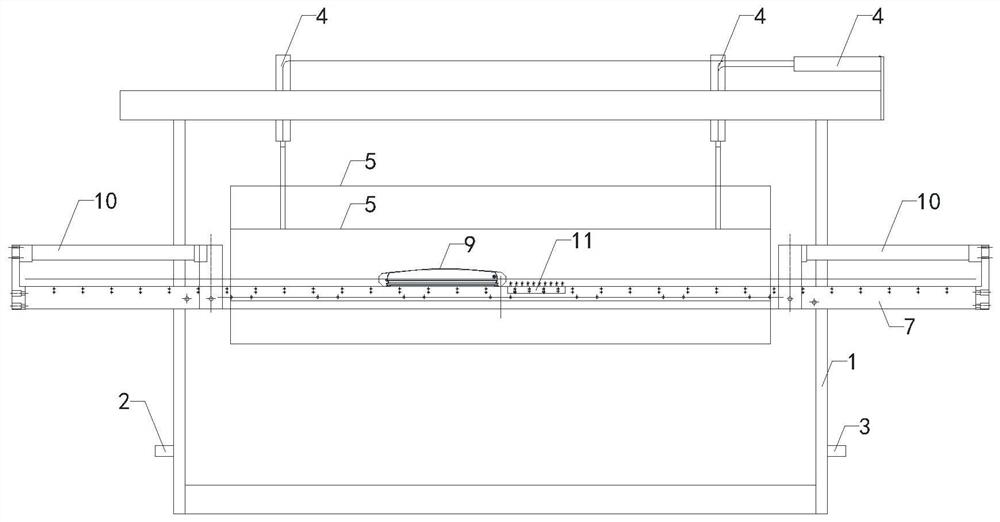

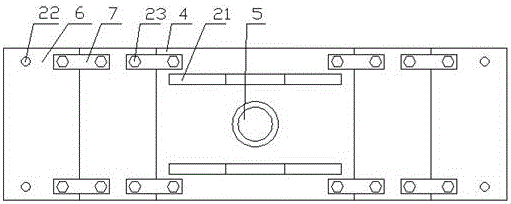

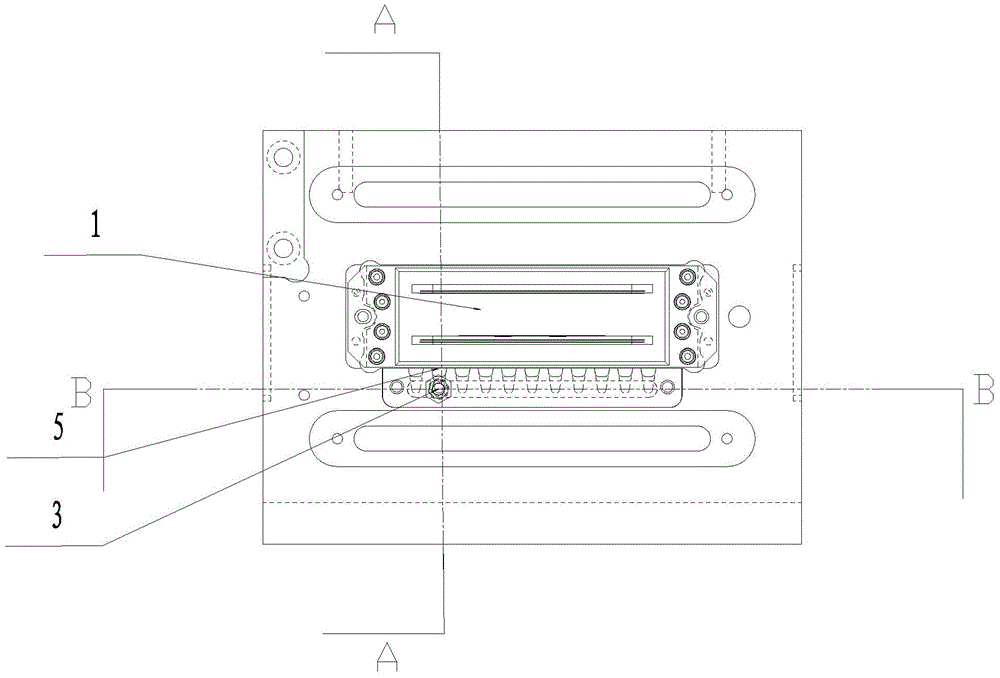

Automatic detection equipment for electrical control panel

PendingCN114779055AReduce testing costsIncrease contact areaCoupling contact membersWork benchesElectrical controlElectrically conductive

The invention provides an electrical control panel automatic detection device, and relates to the technical field of electrical control panel detection, and the electrical control panel automatic detection device comprises a workbench, the two sides of the upper surface of the workbench are fixedly provided with installation plates, and a placement table is movably installed between the two installation plates; a workpiece positioning mechanism used for fixing a workpiece is arranged on the upper surface of the containing table, and a driving mechanism used for driving the containing table to move is arranged on one side of the workbench. Through the wavy design of the annular metal connecting sheet, the annular metal connecting sheet can be changed according to the shape of the spherical contact on the surface of the circuit board under the connection action of the auxiliary spring, so that the contact area between the annular conductive block and the contact on the circuit board and the contact between the annular metal connecting sheet and the contact on the circuit board can be larger; contact breaking conditions can be effectively reduced, detection work can be better facilitated, and the detection contact can be suitable for detection contacts of different sizes on electrical control panels of different models due to the change of the overall shape of the annular metal connecting piece.

Owner:XIAN JIAOTONG UNIV CITY COLLEGE

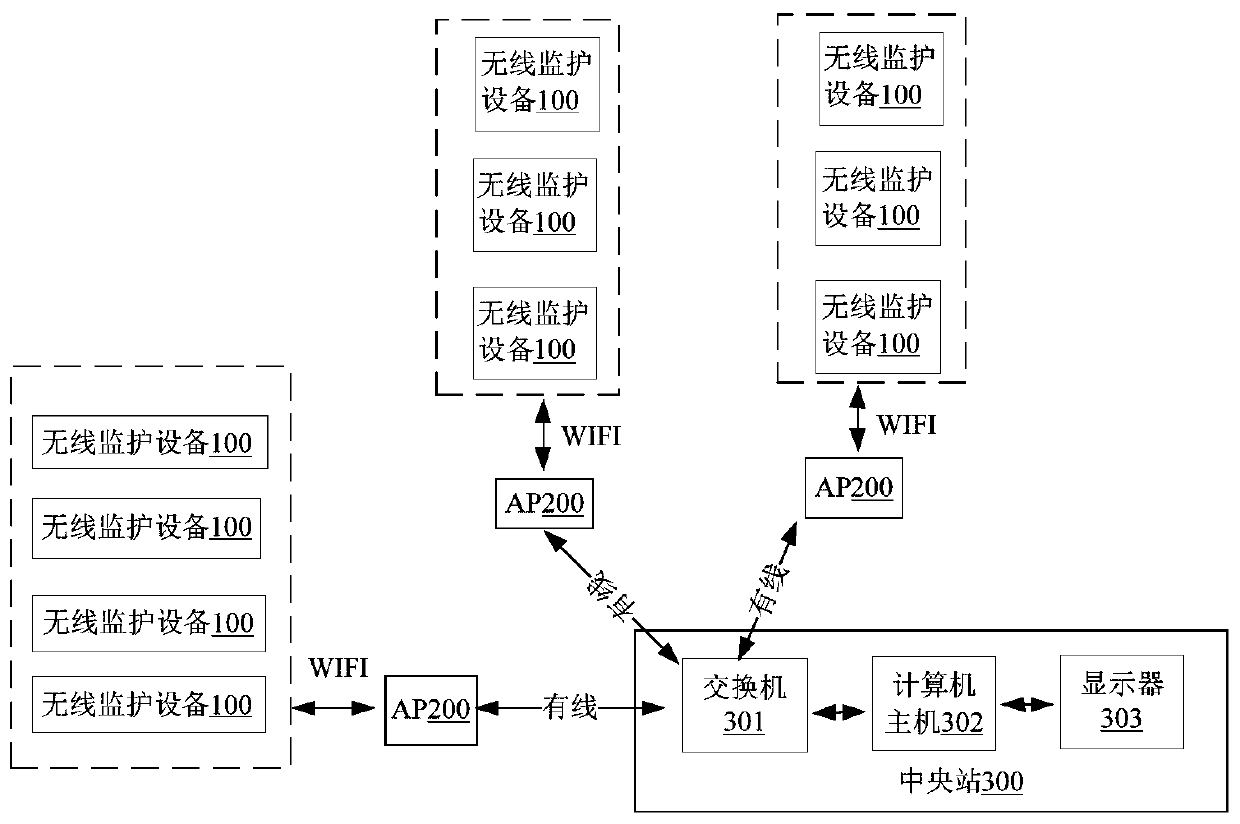

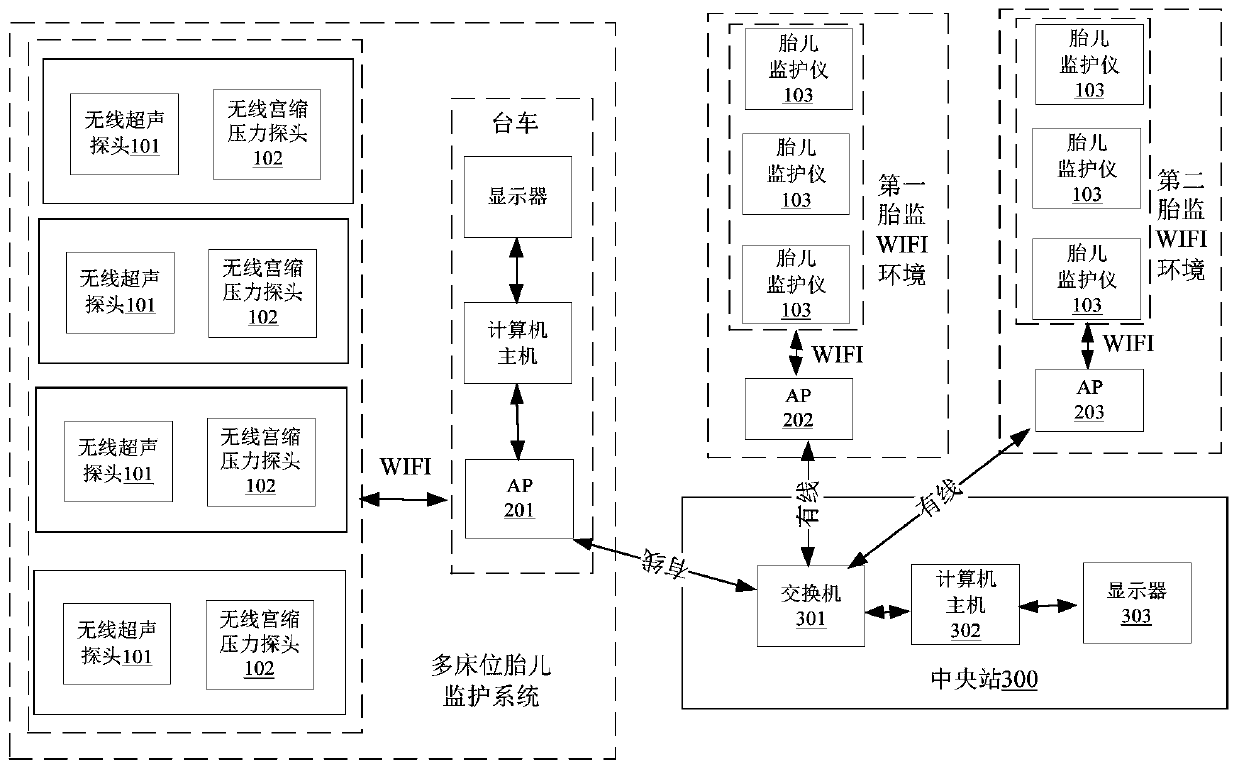

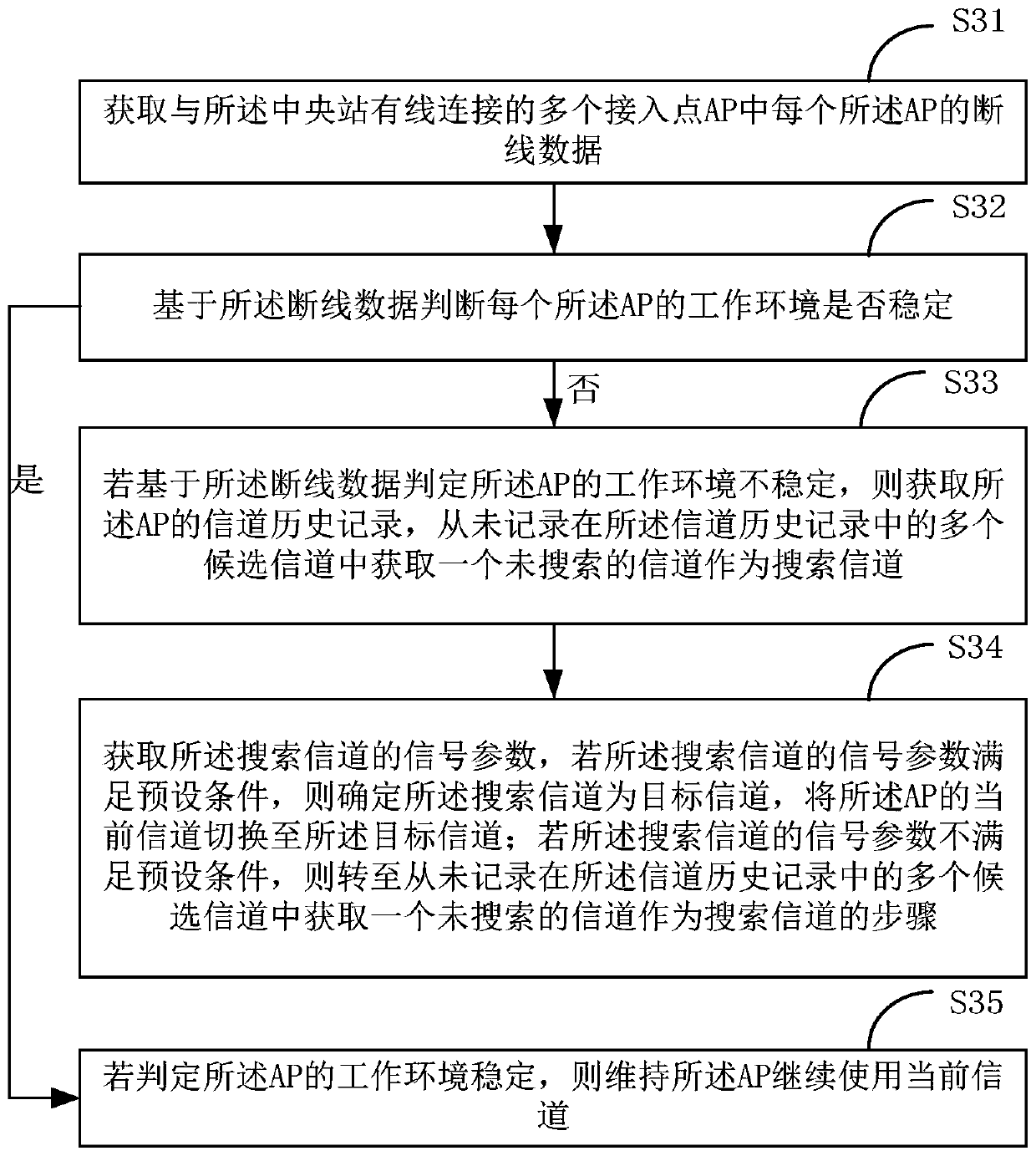

Network channel adjustment method, device, terminal, system and medium

The invention belongs to the technical field of medical monitoring, and particularly relates to a network channel adjustment method and device, a terminal, a system and a medium, and the method comprises the steps: obtaining the disconnection data of each AP in a plurality of APs in wired connection with a central station; judging whether the working environment of each AP is stable or not based on the disconnection data; if it is judged that the working environment of the AP is unstable based on the disconnection data, obtaining a channel historical record of the AP, and obtaining an unsearched channel from a plurality of candidate channels which are not recorded in the channel historical record to serve as a search channel; acquiring a signal parameter of the search channel, if the signal parameter of the search channel satisfies a preset condition, determining the search channel as a target channel, and switching the current channel of the AP to the target channel; and if the signalparameter of the search channel does not meet the preset condition, turning to the step of obtaining an unsearched channel from a plurality of candidate channels which are not recorded in the channelhistory as a search channel. The stability of communication of the whole network system is improved.

Owner:EDAN INSTR

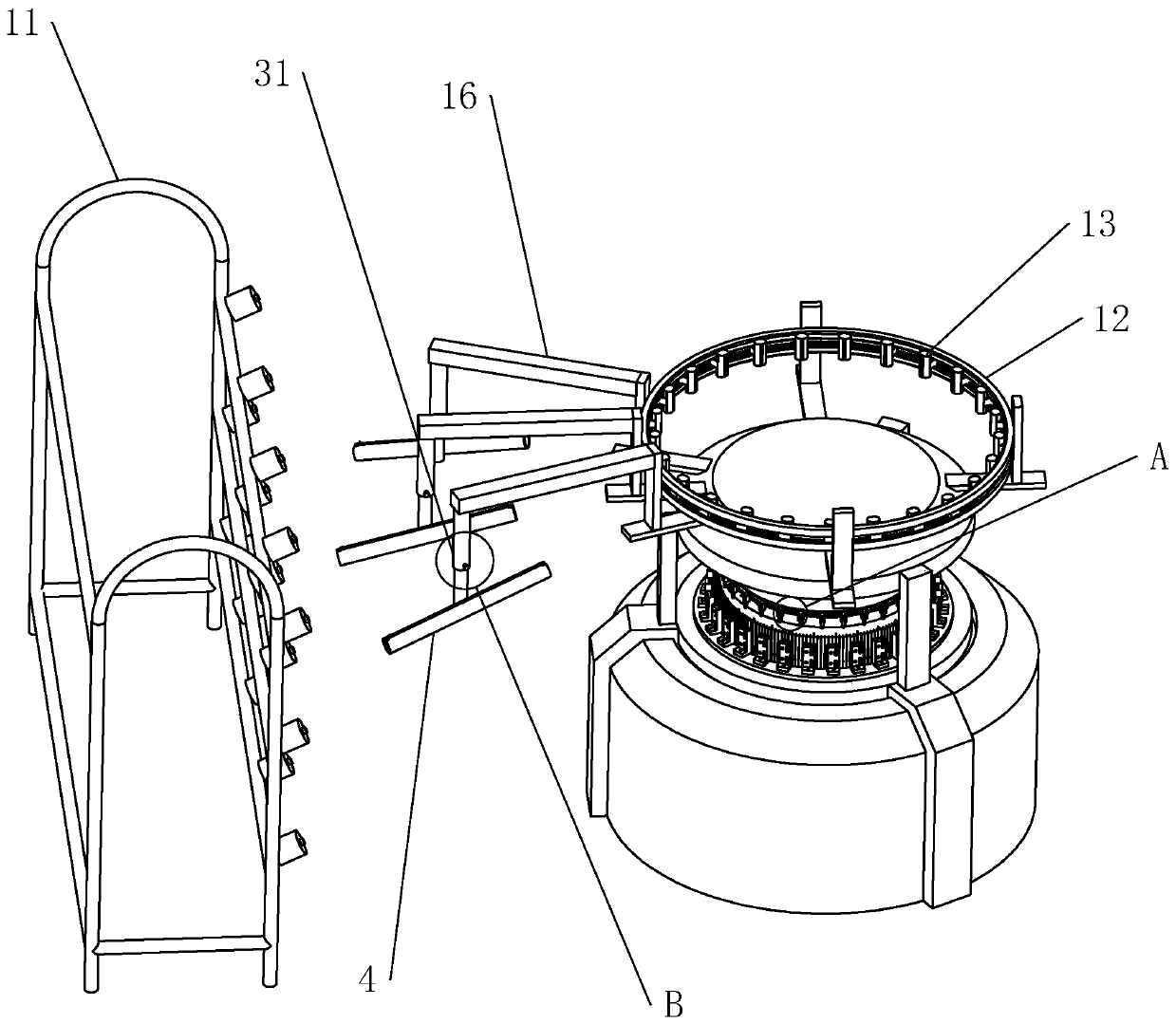

A Yarn Feeding Mechanism of Large Circular Knitting Machine

The invention relates to the technical field of circular knitting machines, and discloses a yarn feeding mechanism of a circular knitting machine. The yarn feeding mechanism of the circular knitting machine includes a creel, a support ring, a yarn storage device and a yarn feeding opening, wherein the creel is placed on the ground around the circular knitting machine, the support ring is arrangedon a rack of the circular knitting machine, the yarn storage device is arranged on the support ring, and the yarn feeding opening is formed in a dial of the circular knitting machine; a height liftingassembly is arranged between the creel and the yarn feeding mechanism and includes a height retractable part and a lifting pulley, the lifting pulley is arranged on the height retractable part, the lifting pulley is located at the height between the creel and the yarn storage device, and yarn on a yarn ring of the creel is unwound and then bypasses the lifting pulley to be imported into the yarnstorage device. According to the yarn feeding mechanism of the circular knitting machine, the lifting pulley is adopted to lift the yarn between the creel and the yarn storage device, the yarn is prevented from being touched when workshop workers walk, tidiness of the yarn is improved, and the yarn is prevented from breaking.

Owner:绍兴美科针纺有限公司

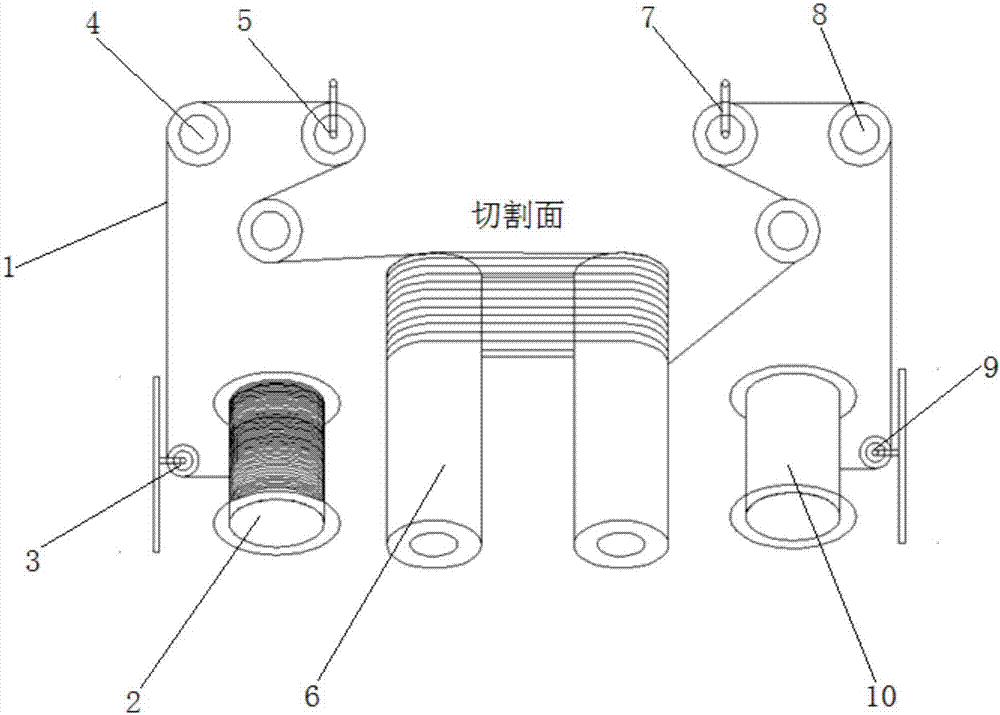

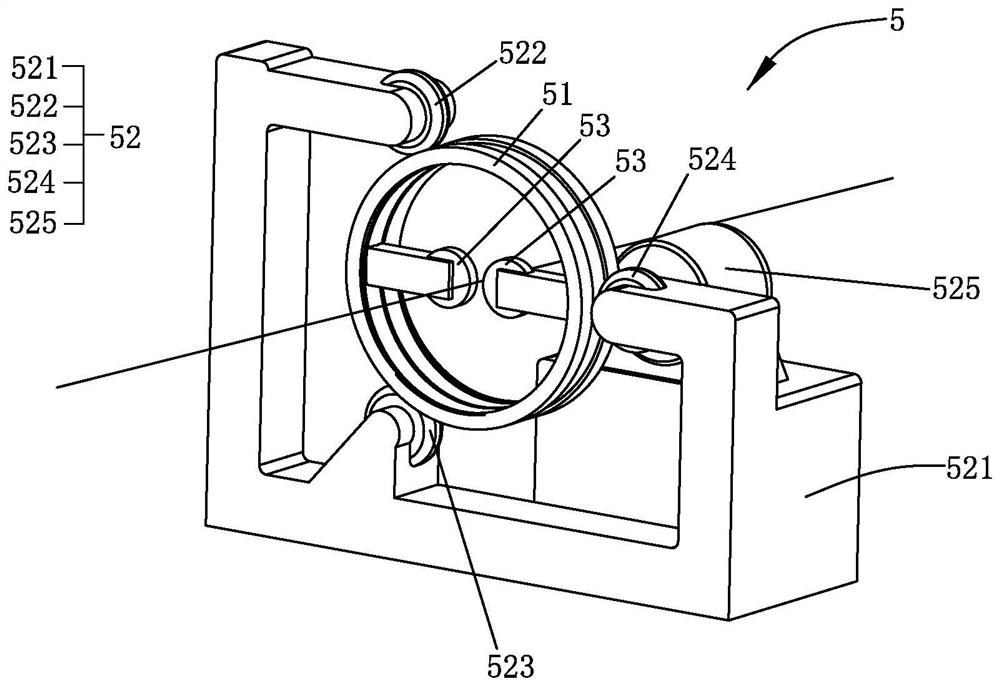

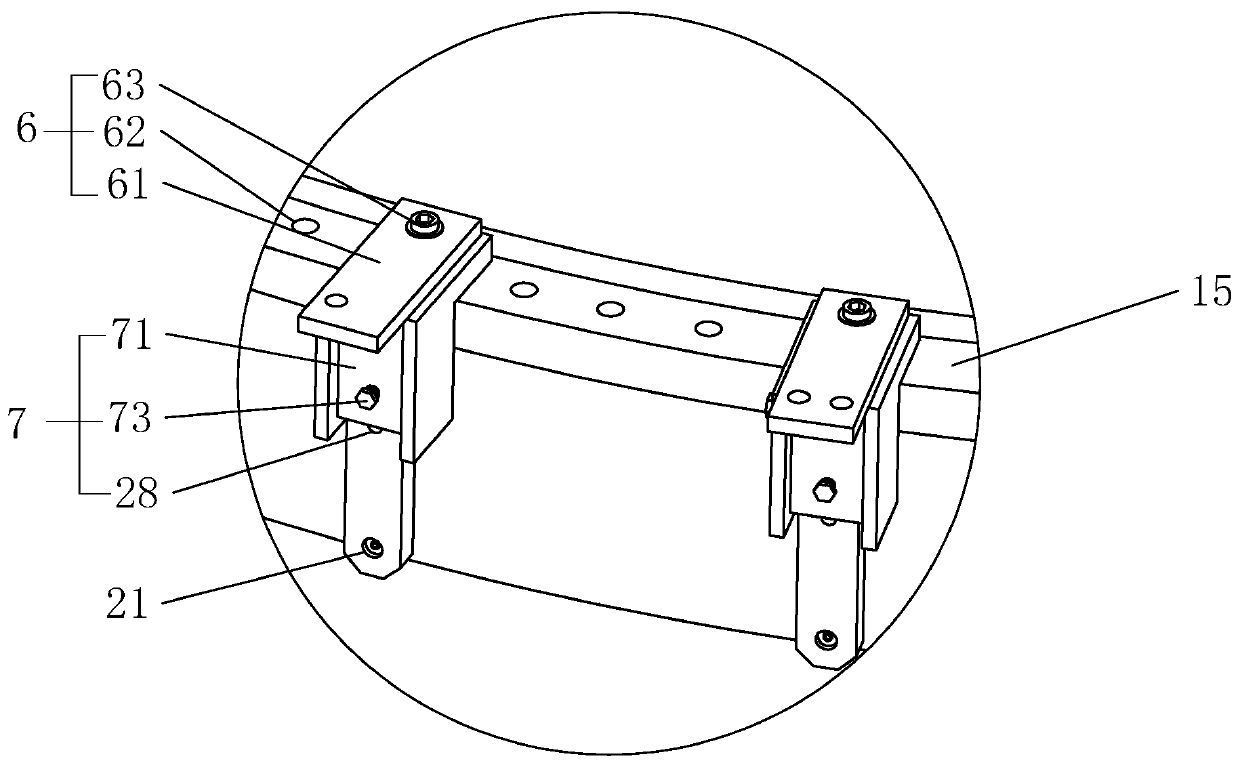

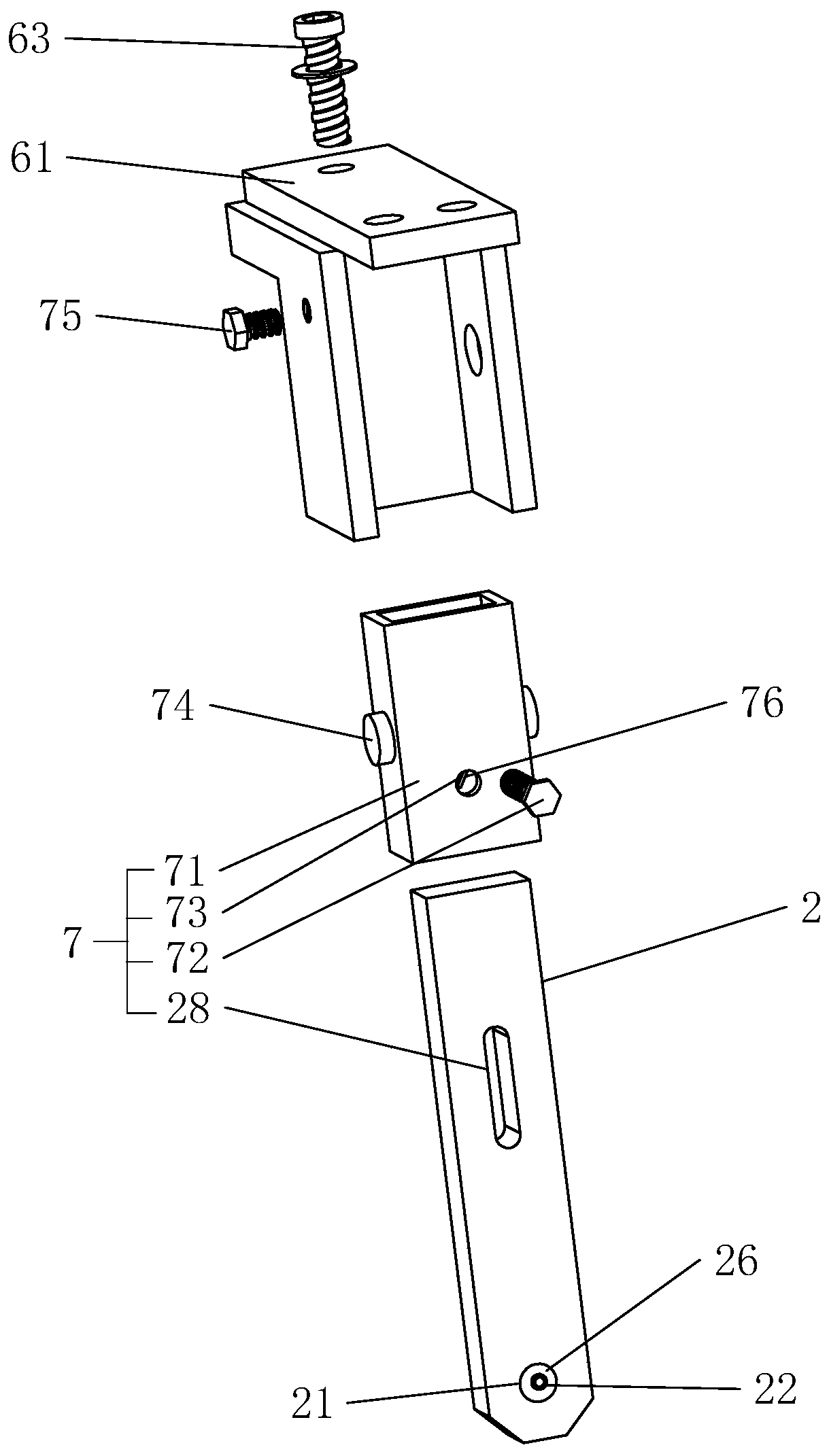

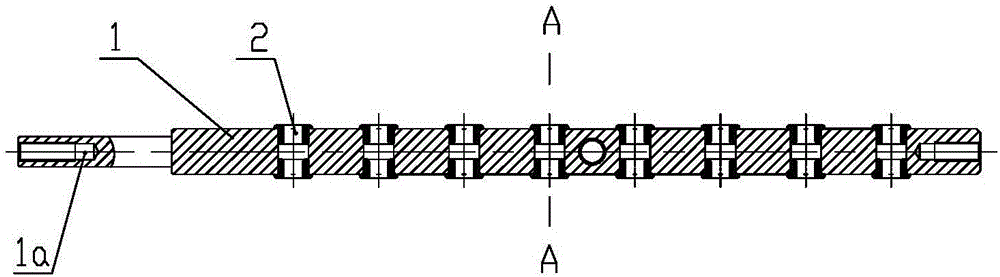

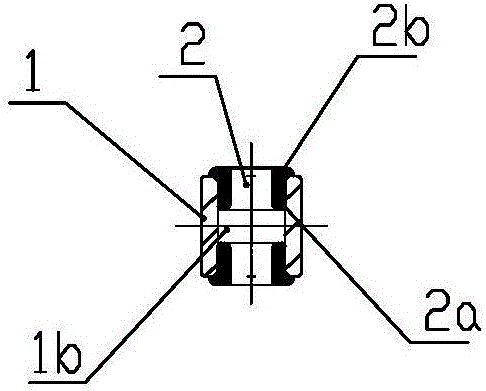

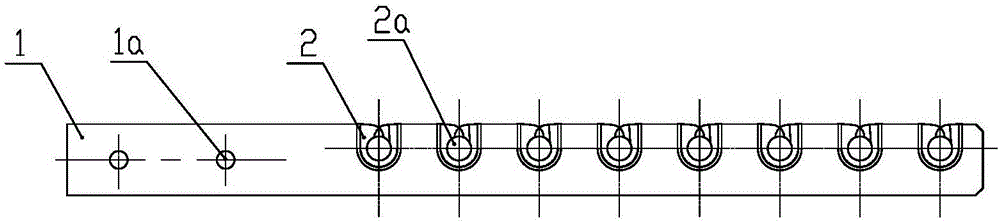

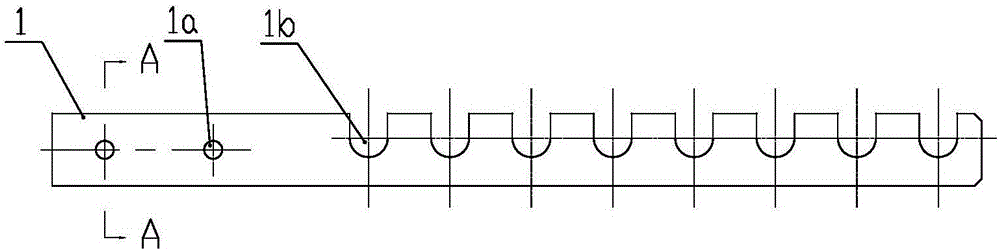

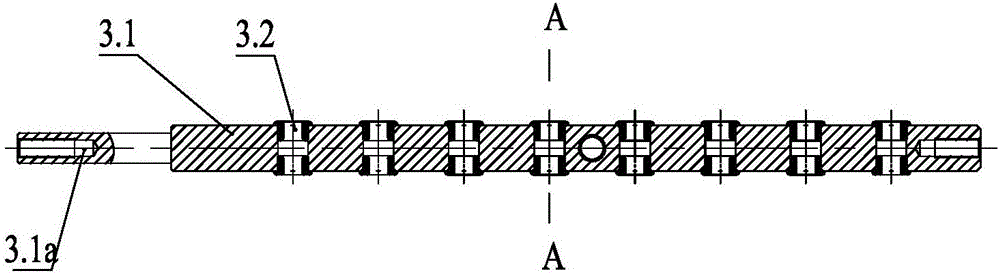

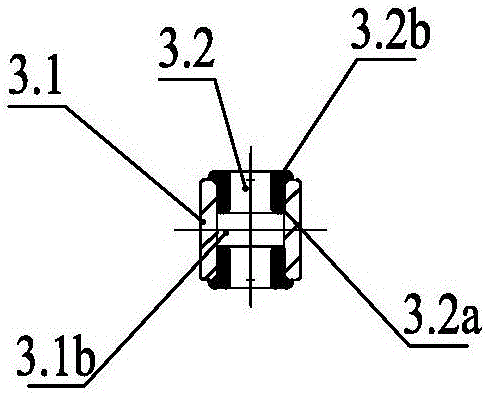

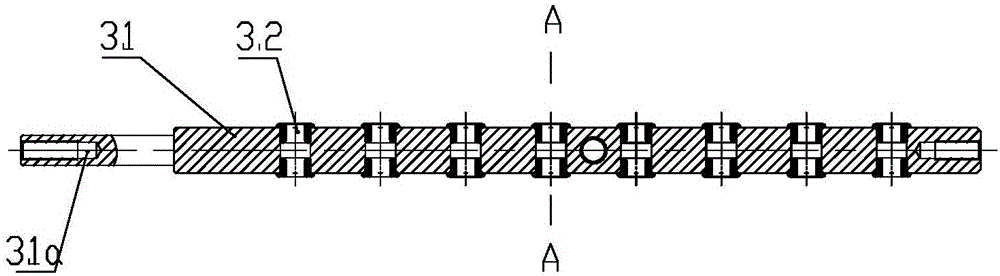

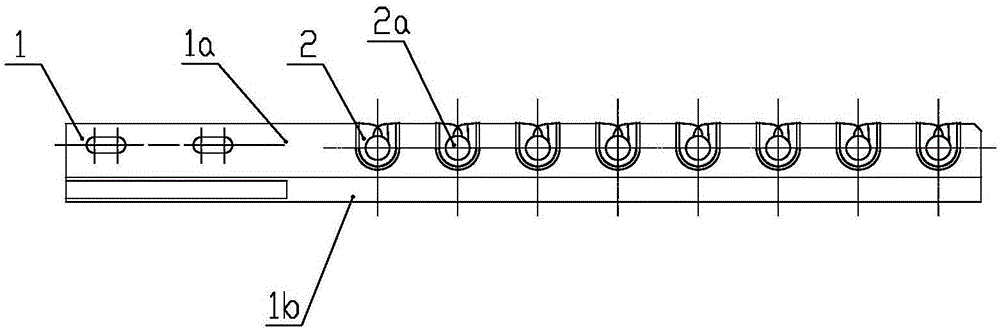

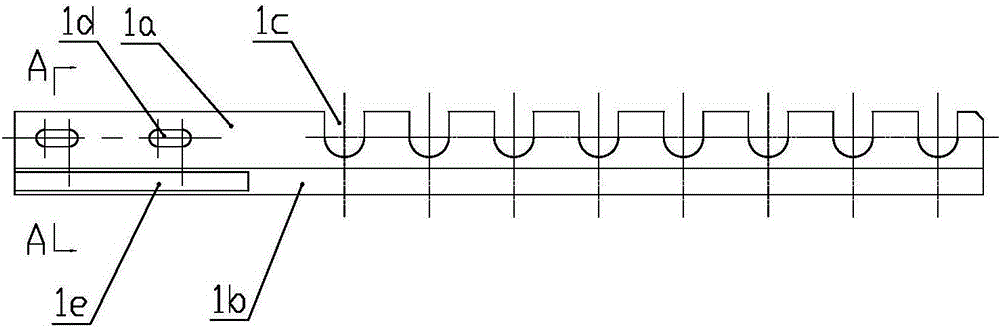

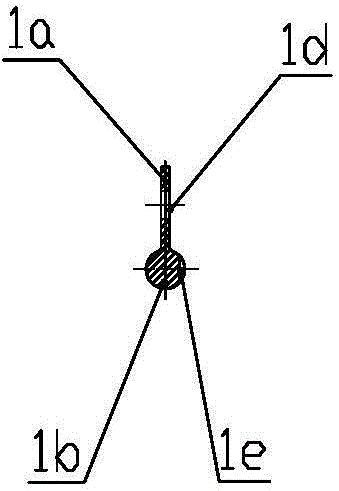

Incoming and outgoing line yarn guiding rod assembly of single-tube yarn feeder

The invention relates to an incoming and outgoing line yarn guiding rod assembly of a single-tube yarn feeder. The incoming and outgoing line yarn guiding rod assembly is characterized by comprising a yarn guiding rod and yarn guiding rings; threaded mounting holes are formed in the end faces of two ends of the yarn guiding rod; a plurality of yarn ring mounting holes are uniformly formed in the yarn guiding rod in the length direction; the yarn guiding rings are detachably assembled in the yarn ring mounting holes; and a yarn guiding hole is formed in the center of each yarn guiding ring. The incoming and outgoing line yarn guiding rod assembly is compact in structure and reasonable in design, smooth and unimpeded guiding can be provided when yarns enter into or come out of the yarn feeder, the occurrence of a yarn breaking condition is reduced, and the work efficiency and the product quality are improved.

Owner:WUXI YINLIAN GEAR MACHINERY CO LTD

Yarn guide rod assembly of single-tube yarn feeder

The invention relates to a yarn guide rod assembly of a single-tube yarn feeder. The yarn guide rod assembly is characterized by comprising a yarn guide rod and a yarn guide ring, wherein the yarn guide rod is of a flat sheet shape; a mounting hole is formed in one end of the yarn guide rod; a plurality of yarn coil mounting grooves are uniformly distributed in the yarn guide rod along the length direction; the yarn guide ring is assembled in the yarn coil mounting grooves in a detachable manner; and a yarn guide hole is formed in the center of the yarn guide ring. The yarn guide rod assembly of the single-tube yarn feeder is compact in structure and reasonable in design, can provide smooth and block-free guidance to yarns and reduce a condition that the yarns are broken, so that the working efficiency and the product quality are improved.

Owner:WUXI YINLIAN GEAR MACHINERY CO LTD

A digital printing machine

ActiveCN107284029BIncrease temperatureUniform temperatureInking apparatusOther printing apparatusComputer terminalDigital printing

The invention discloses a digital printing machine, which solves the problem that when the digital printing machine is discharging ink, the flow rate of the dyestuff will be unequal due to the low ambient temperature or the uneven temperature of the ink. The main points of the technical solution for the problem of broken lines in the image are: the ink outlet head is also equipped with a heating device connected to the main control terminal, the printing machine body is also equipped with a thermal lighting device, and the printing machine body is also equipped with a drying device The printing machine body is also provided with a preheating device, and the side of the printing machine away from the workbench is also provided with a cloth detection device. The cloth detection device detects the cloth and outputs a cloth detection signal to the main control terminal, and the main control terminal controls the preheating device, The thermal lighting device, the heating device, and the drying device are activated. A digital printing machine of the present invention heats the ink outlet head, thereby increasing the temperature of the ink, making the temperature of the ink more uniform, and reducing the situation of image disconnection.

Owner:NANTONG JINKANGHONG TEXTILE CO LTD

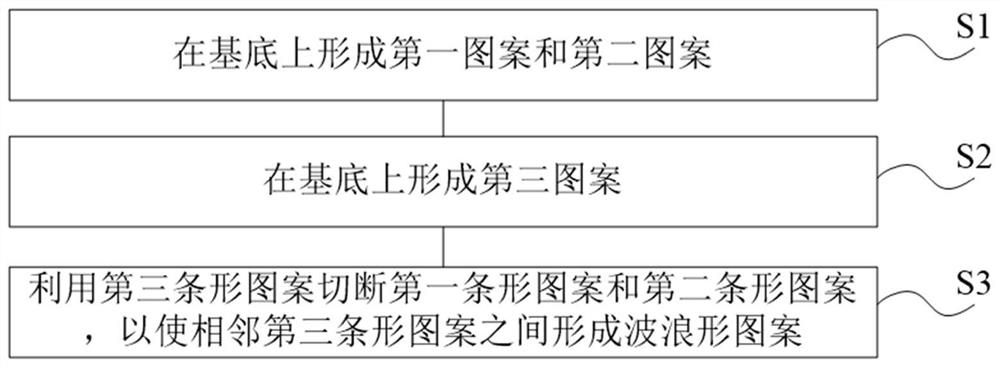

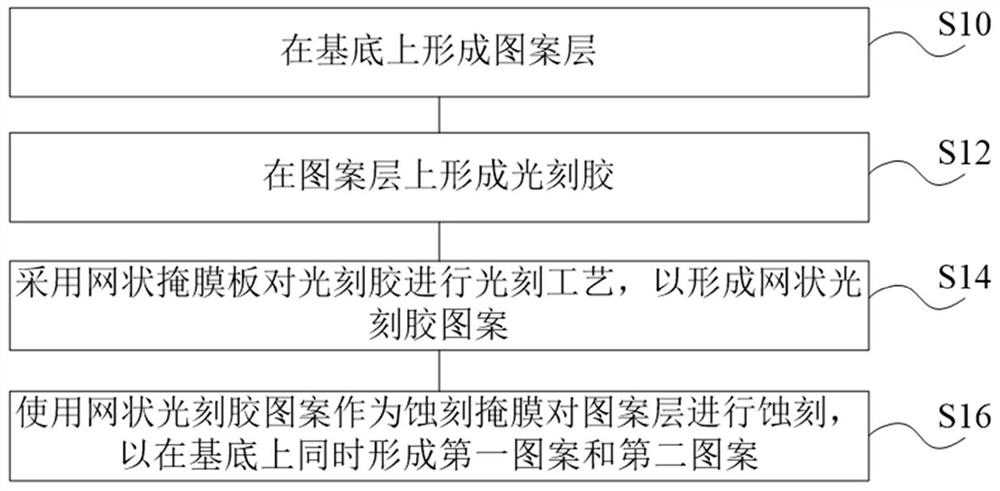

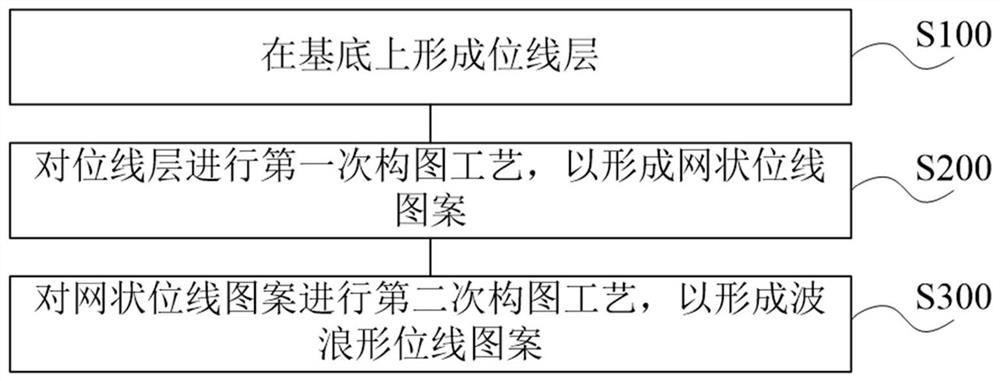

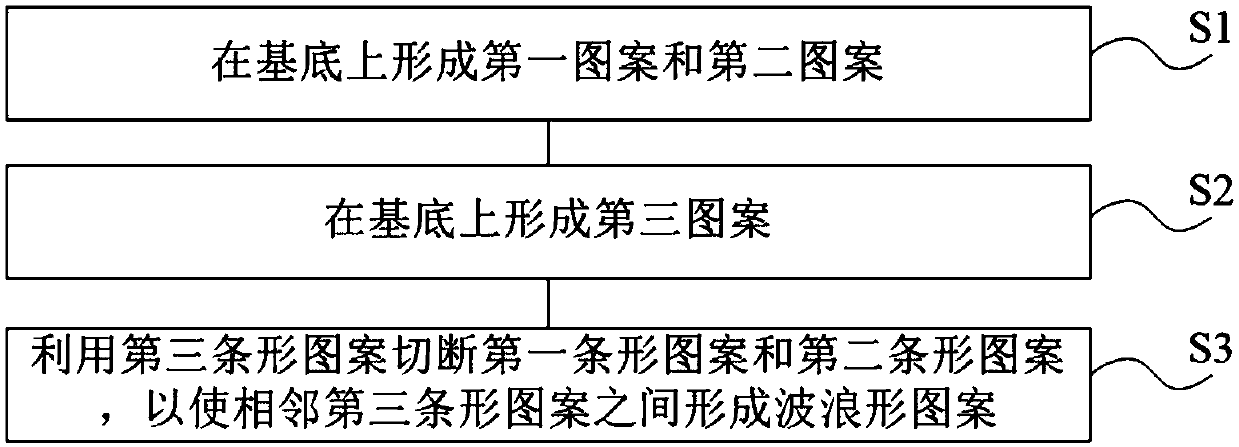

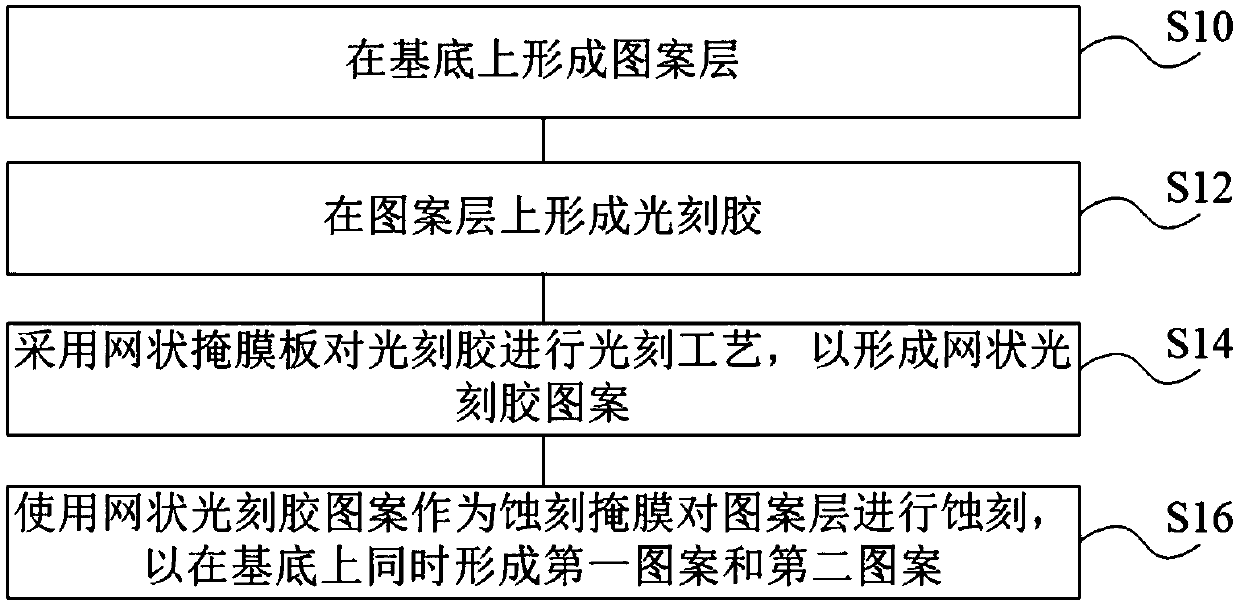

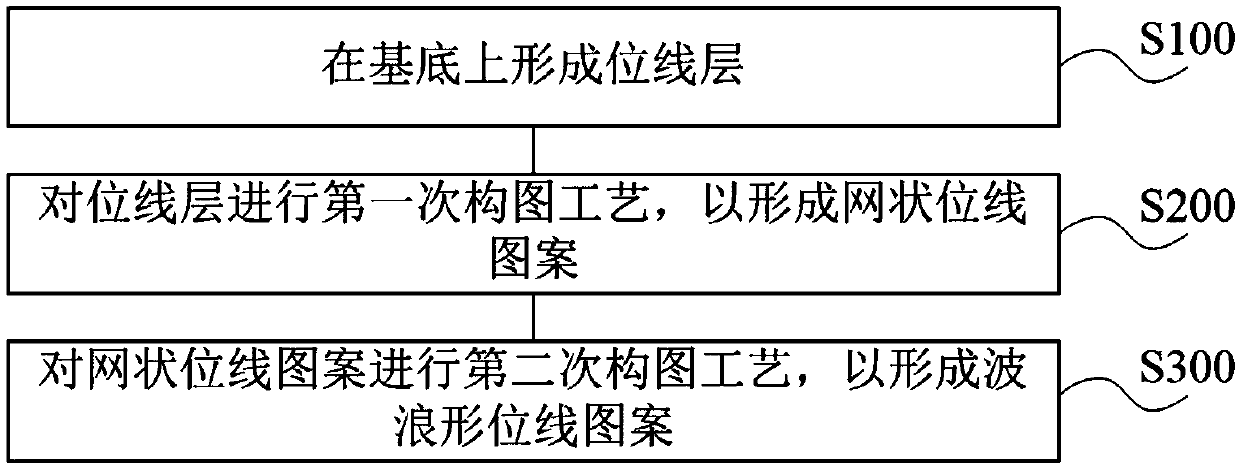

Wavy pattern of integrated circuit and method of forming same, integrated circuit

ActiveCN111192818BImprove manufacturing yieldReduce disconnectionsSemiconductor/solid-state device manufacturingMechanical engineeringSemiconductor

The present application relates to the technical field of semiconductor fabrication, and in particular, to a method for forming a wavy pattern of an integrated circuit, a wavy pattern of an integrated circuit, and an integrated circuit, wherein the method for forming the wavy pattern includes: forming a wavy pattern on a substrate The first pattern and the second pattern, the first pattern includes a plurality of first bar-shaped patterns arranged at intervals in the first direction, and the second pattern includes a plurality of first bar-shaped patterns arranged at intervals in the second direction and connected to the first bar-shaped pattern Intersecting second strip pattern; forming a third pattern on the substrate, the third pattern is located on the first pattern and the second pattern, and the third pattern includes a plurality of spaced in the third direction and is arranged with the first strip pattern and the second pattern. The third bar pattern where the second bar pattern intersects; the first bar pattern and the second bar pattern are cut off by using the third bar pattern, so that a wavy pattern is formed between adjacent third bar patterns. Such a design can reduce the disconnection of the wavy pattern and improve the manufacturing yield of the integrated circuit.

Owner:CHANGXIN MEMORY TECH INC

Automatic pressure-reducing type bobbin loader

The invention relates to an automatic pressure-reducing type bobbin loader and belongs to the field of auxiliary equipment for drawing and coiling steel wires. The automatic pressure-reducing type bobbin loader comprises a disc-shaped base plate and a conical drum wound with steel wires, wherein the drum is fixed on the base plate; a hollow protecting pillar is fixed at the center of circle of thebase plate; a rotating shaft is arranged in the protecting pillar; one end of the rotating shaft is fixedly connected with a plane bearing while the other end is fixedly connected with the rotating shaft of the plane bearing (decelerating effect) through a nut; the lower end of the plane bearing is fixed with the base plate; the lower end of the plane bearing is arranged on the base and is connected with the interior of the base. The structure is simple and the practicability is high; on the basis of the conical design of the drum, the self-adaptive tensioning of the steel wires is realized under the effects of the cycle number increasing and the gravity increasing and the balancing of the tensioning force index is realized; under the effects of the pressure bearing of the plane bearing on the lower part and the speed reduction of the plane bearing on the upper part, the disordered and broken wires are greatly reduced; the subsequent working pressure is also relieved; the working efficiency and the product quality are obviously increased; the potential safety hazard existing in the working process is reduced.

Owner:大连鑫宏利船舶工程有限公司

Single Output Ionizer Backbone

ActiveCN102938304BReduce disconnectionsCompact structureTransformers/inductances coils/windings/connectionsEngineeringStress relief

The invention relates to a framework of a single-output ion generator and belongs to the technical field of high-voltage transformers. The framework comprises an insulating framework body, and the lower ends of two first soldering tin pins penetrate out of first soldering tin pin bases. The lower ends of two second soldering tin pins penetrate out of second soldering tin pin bases. One of a plurality of secondary winding partition plates positioned on the outermost side is provided with a stress relief column. Heat dissipation gaps are arranged at the joints of the first soldering tin pins and the first soldering tin pin bases, heat dissipation gaps are arranged between the second soldering tin pins and the second soldering tin pin bases, and heat dissipation gaps are arranged between third soldering tin pins and a middle partition plate. The framework is compact and reasonable in structure, winding breaking is effectively reduced, product quality is improved, and the production cost is reduced.

Owner:WUXI TOYO ELECTRICAL APPLIANCE

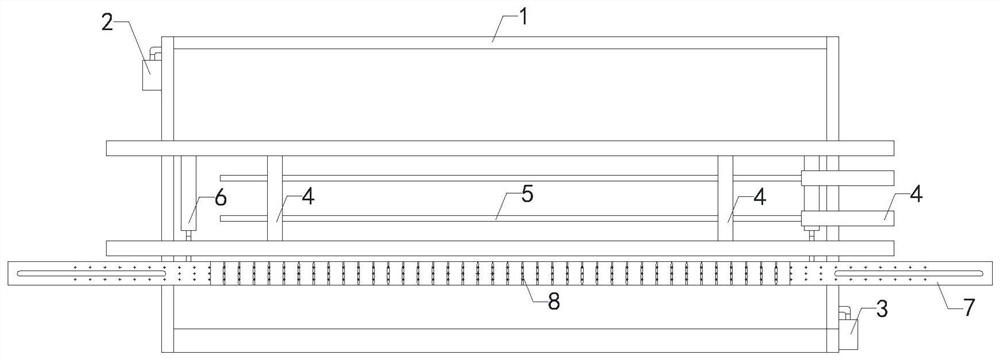

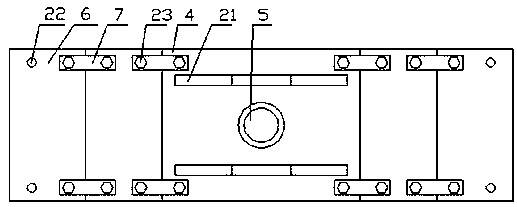

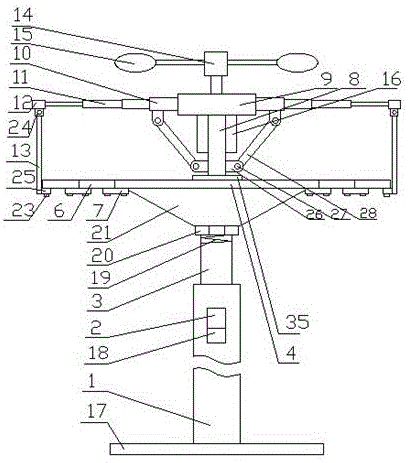

Numerical control aerodynamic shuttle loom

PendingCN112251888AReduce frictionReduce disconnectionsCam shedding mechanismLoomsNumerical controlYarn

The invention relates to the technical field of textile, in particular to a numerical control aerodynamic shuttle loom. The numerical control aerodynamic shuttle loom adopts a shuttle shooting pneumatic device for braking, is simple in action and effective in control; and when a multifunctional air floating shuttle swings left and right, the shuttle shooting pneumatic device moves coordinately, errors are reduced, noise is reduced, and meanwhile the situations of shuttle clamping and yarn breaking are reduced. The numerical control aerodynamic shuttle loom comprises a loom body, a warp let-offpneumatic device, a take-up pneumatic device, a heald frame opening pneumatic device, a heald frame, a beating-up pneumatic device, an air floating guide rail, a multifunctional air floating shuttleand an air floating shuttle hook. The warp let-off pneumatic device and the take-up pneumatic device are fixedly installed on the machine body; the heald frame opening pneumatic device is installed above the machine body; the heald frame is arranged on the heald frame opening pneumatic device; the beating-up pneumatic device is installed on the machine body; a beating-up mechanism is arranged on the beating-up pneumatic device; the air floatation guide rail is transversely installed in the machine body; exhaust holes are formed in the air floatation guide rail; and the multifunctional air floatation shuttle is placed above the air floatation guide rail.

Owner:山东军冠纺织有限公司

Wavy pattern of integrated circuit and forming method thereof and integrated circuit

ActiveCN111192818AReduce disconnectionImprove manufacturing yieldSemiconductor/solid-state device manufacturingIntegrated circuitManufacturing engineering

The invention relates to the technical field of semiconductor manufacturing. Specifically, the invention relates to a forming method of a wavy pattern of an integrated circuit, the wavy pattern of theintegrated circuit and the integrated circuit. The forming method of the wavy pattern comprises the steps that a first pattern and a second pattern are formed on a substrate, the first pattern comprises a plurality of first strip-shaped patterns which are arranged at intervals in the first direction, and the second pattern comprises a plurality of second strip-shaped patterns which are arranged at intervals in the second direction and intersect with the first strip-shaped patterns; a third pattern is formed on the substrate, the third pattern is located on the first pattern and the second pattern, and the third pattern comprises a plurality of third strip-shaped patterns which are arranged at intervals in the third direction and intersect with the first strip-shaped pattern and the secondstrip-shaped pattern; and the first strip-shaped patterns and the second strip-shaped patterns are cut off through the third strip-shaped patterns, so that wavy patterns are formed between the adjacent third strip-shaped patterns. Through the design, the situation that the wavy pattern is broken can be reduced, and the manufacturing yield of an integrated circuit is improved.

Owner:CHANGXIN MEMORY TECH INC

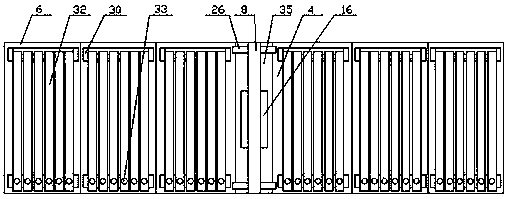

Intelligent spinning system based on yarn winding

ActiveCN114457477AReduce disconnectionReduce the chance of disconnectionDrafting machinesTotal factory controlYarnSpinning

The invention relates to an intelligent spinning system based on yarn winding. The intelligent spinning system comprises a rack, a supply device, a processing device, a wiring device, a first traction device, a second traction device, a first tension detection device, a third traction device, a second tension detection device, a yarn diameter detection device, a winding device, a yarn conveying device, a weaving device and a central control module. The real-time tension of the yarn is detected by arranging the first tension detection device and the second tension detection device, the rotating speed of the second traction device and the rotating speed of the third traction device are adjusted through the central control module, and the tension borne by the yarn is controlled within the standard range. By arranging the yarn diameter detection device and adjusting the rotating speed of the third detection device, the diameter of the yarn is controlled within the standard range, the yarn consumption speed of the knitting device is detected, yarn supply of the knitting device is guaranteed through adjustment, and meanwhile yarn breakage is reduced to the maximum extent.

Owner:江苏格颖纺织有限公司

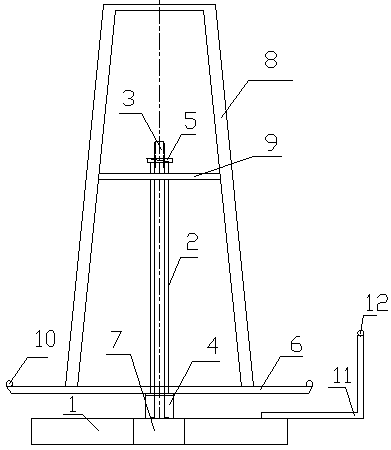

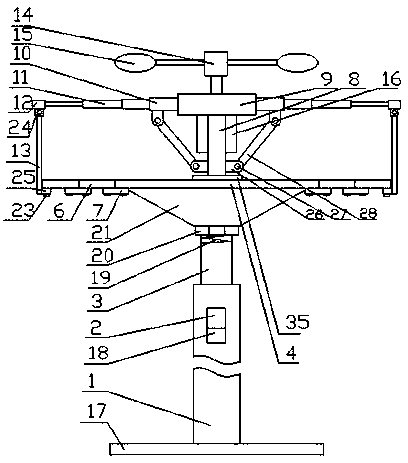

An overhead line tightening device

Owner:PENGLAI POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

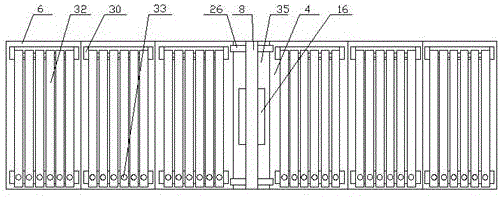

Line tightening device for overhead lines

ActiveCN106129942AHigh strengthImprove wind resistanceOverhead installationScrew jointElectric generator

The invention discloses a line tightening device for overhead lines. The line tightening device comprises a main upright post, wherein an illuminating lamp is arranged at the middle part of the main upright post; an auxiliary upright post is sleeved in the main upright post; the top end of the auxiliary upright post is in screw joint with a thread bushing arranged at the lower part of a main line slot frame; a group of extension line slot frame is arranged on two sides of the main line slot frame respectively; a top end upright plate is arranged at the upper part of the main line slot frame; a top end platform is arranged at the top end of the top end upright plate; extension rods are arranged on two sides of the top end platform respectively; pull rods are arranged at the ends of the extension rods; an electric generator head is arranged at the upper end of the top end platform; the electric generator head is connected with a group of fan blades; and the electric generator head is further electrically connected with a storage battery pack arranged on the top end upright plate. The line tightening device for the overhead lines has an illumination function, wind energy can be used for charging, the device is energy-saving, environmentally-friendly, high in strength and high in anti-wind capacity, and good protection and supporting effects can be provided for overhead power lines, so that the probability of the condition that the power lines are broken is reduced.

Owner:安徽长城仪表线缆有限公司

Method for eliminating texture structure of large-draw-ratio copper wire

PendingCN114054528AImprove errorDrawing dimensions are accurateFurnace typesHeat treatment furnacesDrawing ratioCopper wire

The invention provides a method for eliminating a texture structure of a large-draw-ratio copper wire, and relates to the technical field of copper wire processing. The method for eliminating the texture structure of the large-draw-ratio copper wire comprises the following specific steps that: step 1, a material is put into large drawing equipment; step 2, in a wire drawing process, the surface of the material is coated with a lubricating agent; step 3, during wire drawing, different powers are used for machining by observing changes of the material, high power is adopted for machining the material before the material is obviously processed and hardened, and low power is adopted for machining the material when the material is obviously processed and hardened; and step 4, after wire drawing is completed, the copper wire is subjected to a multi-section annealing process. High power is adopted before the material is obviously processed and hardened, and low power is adopted when the material is obviously processed and hardened, so that the error caused by material springback is improved under the condition that the material meets the processing requirement, and the drawing size of the copper wire is more accurate.

Owner:ANHUI CHUJIANG HIGH TECH ELECTRIC WIRE CO LTD

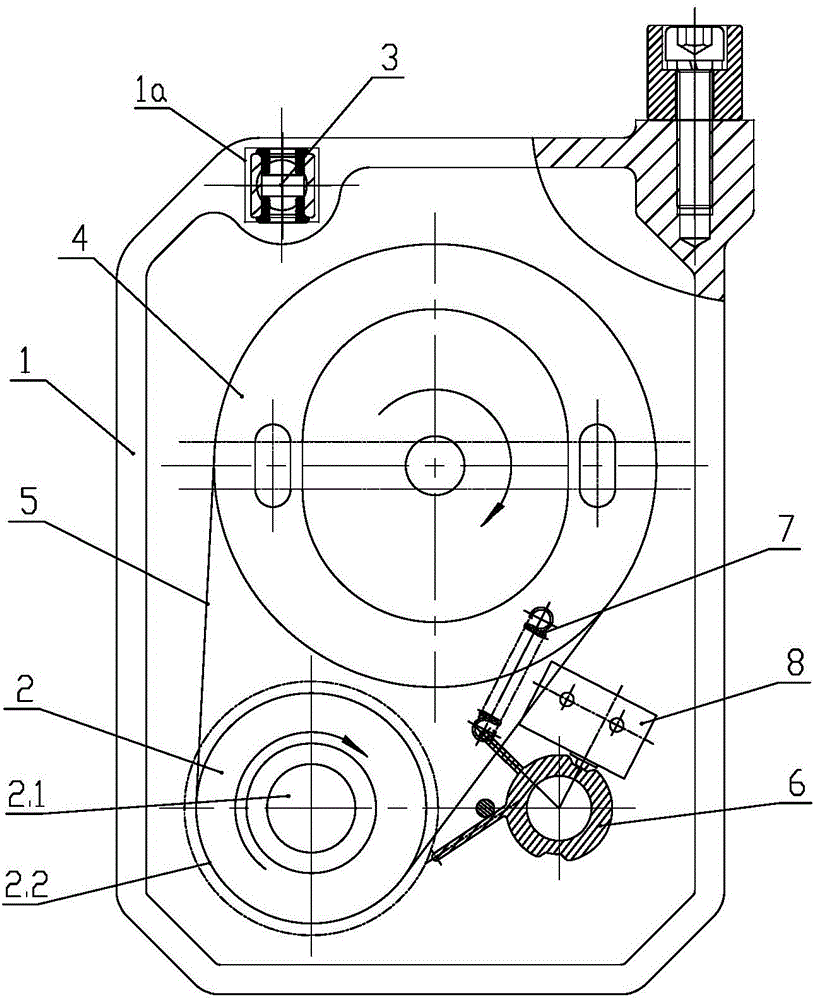

Improved single-tube yarn feeder with pitch adjusting function

The invention relates to an improved single-tube yarn feeder with a pitch adjusting function. A yarn guide rod assembly is installed on a thread inlet yarn guide rod mounting seat at the upper left corner of the top of a single-tube seat. A motor shaft hole is formed in the middle of the upper portion of the single-tube seat. A motor is installed on the single-tube seat. A driving belt wheel is fixedly installed on a motor output shaft. A roller mounting seat is arranged on the lower left portion of the motor shaft hole. The end of a roller mandrel is installed in the roller mounting seat in a supported mode and can move. The roller mandrel is sleeved with a roller drum, and the roller drum can rotate freely. The roller drum is in transmission connection with the driving belt wheel through a transmission belt. Pitch adjusting connecting plates are arranged at the two ends of a roller correspondingly. The small-head end of each pitch adjusting connecting plate is connected to the yarn guide rod assembly in a hinged mode. The big-head end of each pitch adjusting connecting plate is provided with an open mounting groove. The roller mandrel is installed in the open mounting grooves in an embedded mode. A yarn breaking automatic stop mechanism is installed on a microswitch mounting seat and an automatic stop rod supporting seat on the lower right portion of the motor shaft hole. By the adoption of the improved single-tube yarn feeder, the situation of yarn breaking can be effectively reduced, and the operation safety of the equipment is improved.

Owner:WUXI YINLIAN GEAR MACHINERY CO LTD

Single-thread-inlet single-tube yarn feeder

InactiveCN106400287AReduce disconnectionsTimely control stops workingWeft knittingYarnTransmission belt

The invention relates to a single-thread-inlet single-tube yarn feeder. A single tube base is in a square shape, a thread-inlet yarn-guide rod mounting base is arranged on the upper left corner of the top of the single tube base, and a yarn guide assembly is installed on the thread-inlet yarn-guide rod mounting base; a motor shaft hole is formed in the middle of the upper portion of the single tube base, a motor is installed on the rear side wall of the single tube base, an output shaft of the motor stretches out of the motor shaft hole formed in the single tube base to reach the front side of the single tube base, and a drive sprocket is fixedly installed; a roller mounting base is arranged at the bottom left of the motor shaft hole, the end of a roller spindle is installed in the roller mounting base in a supported mode, a roller cylinder is installed on the roller spindle in a sleeving mode and can rotate freely, and the roller spindle is in transmission connection with through a transmission belt; a micro switch mounting base and an automatic-stop rod supporting base are arranged at the bottom right of the motor shaft hole, and a broken-yarn automatic-stop mechanism is installed on the micro switch mounting base and the automatic-stop rod supporting base. By means of the single-thread-inlet single-tube yarn feeder, yarn breaking can be effectively reduced, the safety of equipment operation is improved, and efficient operation of the yarn feeder is guaranteed.

Owner:WUXI YINLIAN GEAR MACHINERY CO LTD

Inner yarn guide rod assembly of single-pipe yarn feeder

The invention relates to an inner yarn guide rod assembly of a single-pipe yarn feeder. The inner yarn guide rod assembly is characterized by comprising a yarn guide rod and a yarn guide ring, wherein the yarn guide rod comprises a long and flat sheet part and a long round rod part; the long round rod part is internally connected onto a lower side edge of the long and flat sheet part; a plurality of yarn ring mounting grooves are uniformly distributed in the long and flat sheet part along the length direction; a mounting hole is formed in one end of the long and flat sheet part; the yarn guide ring is mounted in the yarn ring mounting grooves in a detachable manner; and a yarn guide hole is formed in the center of the yarn guide ring. The inner yarn guide rod assembly is compact in structure and reasonable in design and can provide smooth and obstacle-free guidance to yarns; and a condition that the yarns are broken is reduced, and the working efficiency and the quality of a product are improved.

Owner:WUXI YINLIAN GEAR MACHINERY CO LTD

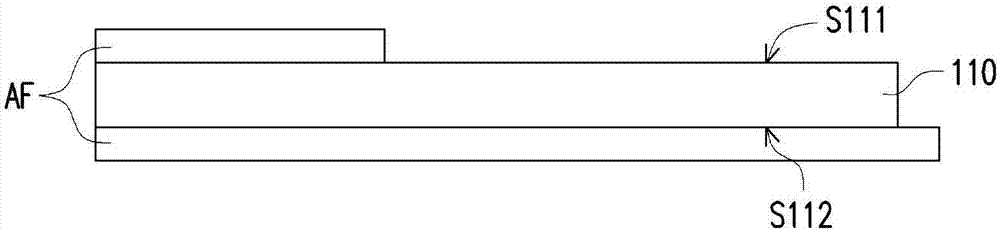

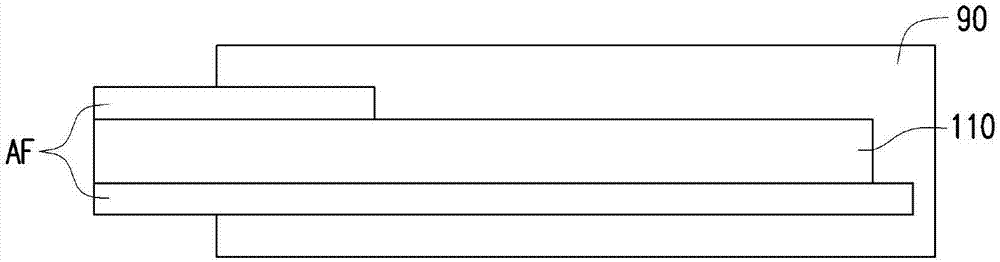

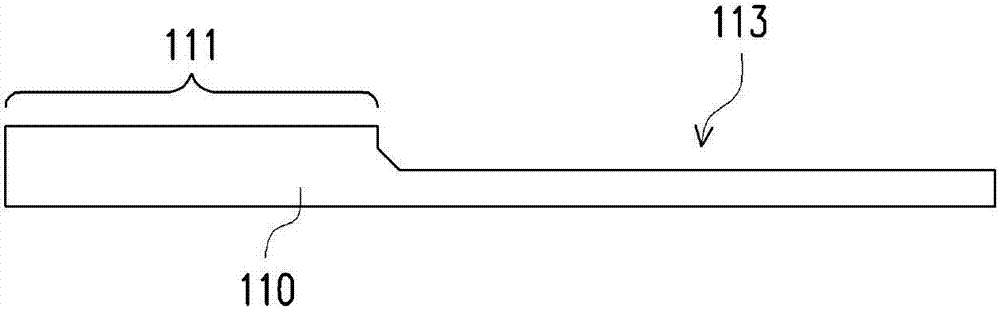

Touch panel and manufacturing method thereof

ActiveCN104516562BReduce disconnectionsReduce height differenceInput/output processes for data processingMetallic materialsComputer science

The invention provides a touch panel and a manufacturing method thereof. The touch panel is used for providing a touch signal. The touch panel comprises a substrate, a first vision shielding layer, an electrode layer and a metal material layer. The substrate is provides with a display region and a first groove part. The first vision shielding layer is partially or completely embedded in the first groove part. One part of the electrode layer is arranged on the display region, while the other part of the electrode layer is arranged on the first vision shielding layer. When an object touches with or is close to the touch panel, the electrode layer correspondingly generates a touch signal. The metal material layer is arranged on the first vision shielding layer and is electrically connected with the electrode layer to transfer the touch signal to a drive element.

Owner:ACER INC

An overhead line tightening device

The invention discloses a line tightening device for overhead lines. The line tightening device comprises a main upright post, wherein an illuminating lamp is arranged at the middle part of the main upright post; an auxiliary upright post is sleeved in the main upright post; the top end of the auxiliary upright post is in screw joint with a thread bushing arranged at the lower part of a main line slot frame; a group of extension line slot frame is arranged on two sides of the main line slot frame respectively; a top end upright plate is arranged at the upper part of the main line slot frame; a top end platform is arranged at the top end of the top end upright plate; extension rods are arranged on two sides of the top end platform respectively; pull rods are arranged at the ends of the extension rods; an electric generator head is arranged at the upper end of the top end platform; the electric generator head is connected with a group of fan blades; and the electric generator head is further electrically connected with a storage battery pack arranged on the top end upright plate. The line tightening device for the overhead lines has an illumination function, wind energy can be used for charging, the device is energy-saving, environmentally-friendly, high in strength and high in anti-wind capacity, and good protection and supporting effects can be provided for overhead power lines, so that the probability of the condition that the power lines are broken is reduced.

Owner:安徽长城仪表线缆有限公司

Automatic nozzle cleaning device and method

The present invention relates to a nozzle automatic cleaning device and method, comprising a printing nozzle, a nozzle mounting plate and an air blowing device, the printing nozzle is fixed on the nozzle mounting plate, the air blowing device is located on the nozzle mounting plate, and the air blowing device includes an air inlet hole and an air blowing hole And the air pump, the air pump is connected with the air inlet, the air inlet is connected with the air outlet, the air blow hole is provided with a long and narrow air hole, and the gas is blown out from the long and narrow air hole of the air blow hole. A method for removing impurities such as paper powder, toner, and dust particles on the surface of the nozzle. An automatic cleaning device is added to the nozzle mounting plate, which is efficient, clean, and will not cause damage to the nozzle. Through the air blowing principle of the air blowing hole on the nozzle mounting plate, the paper powder, toner, dust particles and other sundries on the surface of the nozzle are blown away. No need to stop the machine, no need to manually wipe the nozzle, timely maintenance, simple and easy to operate. Reduce the interruption of the nozzle printing process, ensure the normal operation of printing, improve production efficiency, and ensure the quality of printing images.

Owner:杜怀月

Method of cutting ingot by wire-cutting mesh

The invention discloses a method of cutting an ingot by a wire-cutting mesh, and relates to the technical field of solar ingot cutting. The method includes 1, measuring the tops and bottoms of two silicon blocks, and marking cutting positions, namely 2 to 3mm widths reserved on the tops and bottoms of the two silicon blocks, when a machine with a saw cuts, and cutting; 2, bonding a tray and glass, then bonding the two silicon blocks, reserving a gap 3 to 5mm in width between the two silicon blocks, and finishing producing the ingot; 3, marking effective cutting lengths of the silicon blocks, then loading the ingot on a fret-saw machine, weaving a mesh on a guide wheel till extending 10mm length of a non-cutting area between the two silicon blocks, cutting the mesh in the non-cutting area between the two silicon blocks, tying knots, weaving the mesh continuously till finishing, and wrapping the knots on a winding shaft. By the aid of the method, the wire-cutting mesh can be operated without pulleys, product qualified rate can be increased, and production efficiency, operation rates and capacity can be improved greatly.

Owner:HENGSHUI YINGLI NEW ENERGY

A method for detecting the overall additional tension of a multi-wire cutting machine

ActiveCN107214868BAdjust the running status in timeReduce disconnectionsWorking accessoriesFine working devicesWire cuttingDiamond

The invention discloses an integrally additional tension detecting method for a multi-wire cutting machine. The integrally additional tension detecting method for the multi-wire cutting machine comprises the following steps that diamond wires with busbar diameter of 50-80 [mu]m are arranged on the multi-wire cutting machine, and wire arrangement is conducted; and limit wire-running tension of the multi-wire cutting machine operated stably under the non-cutting state is measured, the integrally additional tension of the multi-wire cutting machine is obtained by the difference between breaking tension of the diamond wires and maximum wire-running tension. The integrally additional tension detecting method for the multi-wire cutting machine is applicable to cutting machines of different models and different manufactures are applicable, the detected machine range is wide, operation is simple and convenient, transforming for machines and extra addition of auxiliary devices are not required, detecting cost is low, and popularization is easy.

Owner:杨凌美畅新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com