A Yarn Feeding Mechanism of Large Circular Knitting Machine

A technology of yarn feeding mechanism and circular knitting machine, which is applied in the direction of textiles and papermaking, knitting, weft knitting, etc. It can solve the problems affecting the knitting quality of large circular knitting machines, yarn tension changes, easy-to-dirty yarns, etc., and achieve stable transmission effect , reduce yarn breakage, and protect the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

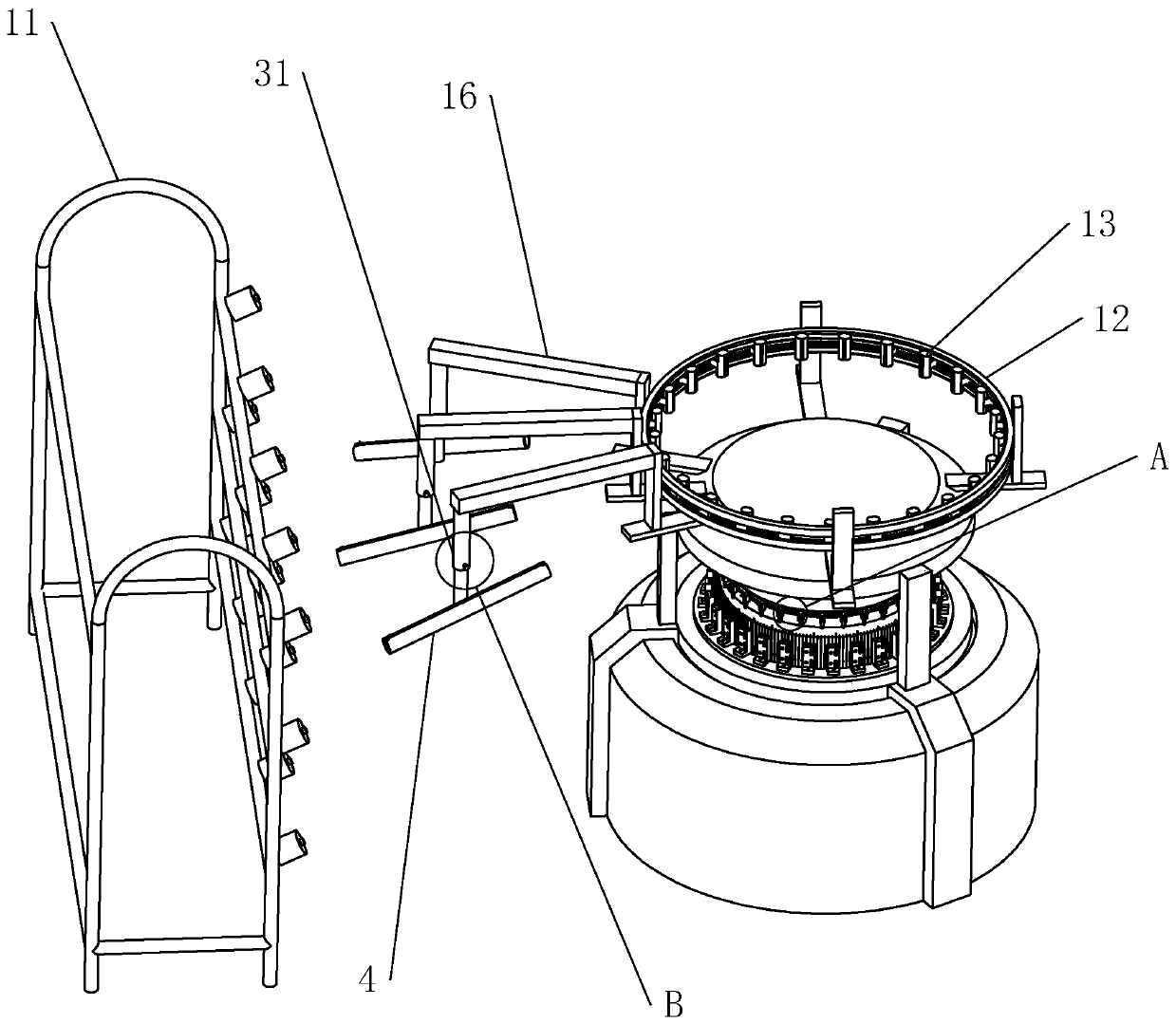

[0044] A yarn feeding mechanism of a large circular knitting machine, such as figure 1 and figure 2 As shown, it includes a creel 11, a support ring 12, a yarn storage device 13 and a yarn feeding nozzle 2. The creel 11 is placed on the ground around the circular knitting machine, and the support ring 12 is coaxially arranged with the dial 14 of the large circular knitting machine and fixed on the large circular knitting machine. On the frame of the machine, a plurality of yarn storage devices 13 are provided and arranged on the support ring 12, and a plurality of yarn storage devices 13 are distributed along the circumferential direction of the support ring 12. 14 is a yarn feeding frame 15 coaxially arranged, and a plurality of yarn feeding nozzles 2 are arranged on the yarn feeding frame 15 along the circumferential direction of the yarn feeding frame 15.

[0045] Such as figure 1 , Figure 7 as well as Figure 8 As shown, a height raising member 3 is arranged between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com