Incoming and outgoing line yarn guiding rod assembly of single-tube yarn feeder

A yarn guide rod and yarn feeder technology, applied in textile and papermaking, weft knitting, knitting and other directions, can solve the problems of unsteady yarn conveying, unstable tension, yarn breakage, etc., to improve work efficiency and product quality, reduced yarn breakage, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

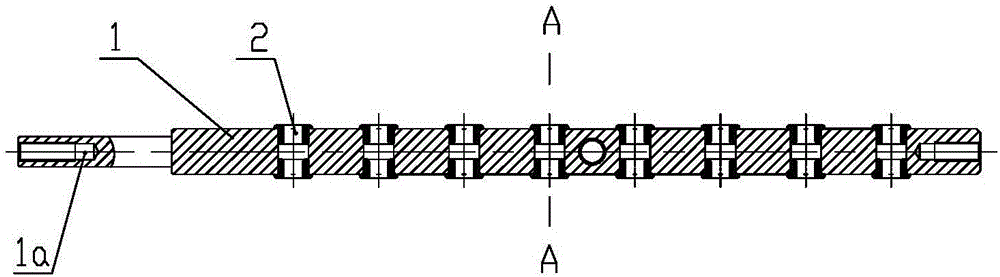

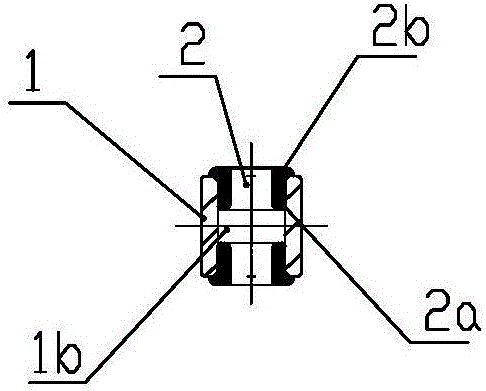

[0013] As shown in the figure: the thread guide rod assembly of the single-tube yarn feeder in the embodiment is mainly composed of a yarn guide rod 1 and a yarn guide ring 2, and threaded mounting holes 1a are provided on the end faces of the two ends of the yarn guide rod 1 , a number of yarn loop installation holes 1b are evenly distributed along the length direction on the yarn guide rod 1; hole.

[0014] Such as figure 1 , figure 2 As shown, in this embodiment, the yarn ring installation hole 1b is circular, the yarn guide ring 2 includes a circular cylinder 2a and an annular flange 2b connected to one end of the circular cylinder 2a, the yarn guide ring 2 The circular barrel 2a is tightly fitted in the loop installation hole 1b, the lower surface of the annular flange 2b of the yarn guide ring 2 is close to the surface of the yarn guide rod 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com